Novel tool clamp for non-ferrous metal machining

A non-ferrous metal and tooling fixture technology, applied in the field of tooling fixtures, can solve problems such as inconvenient clamping force, poor stability of metal materials, cumbersome fixture operation, etc., to avoid loose clamping, improve work efficiency, and reduce labor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

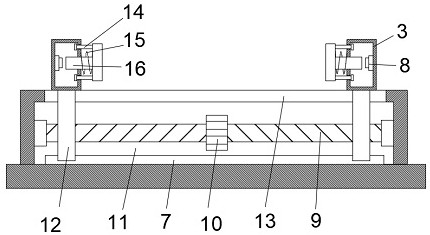

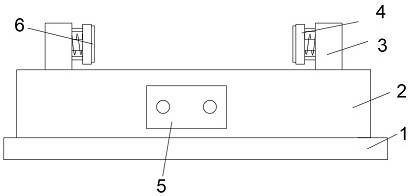

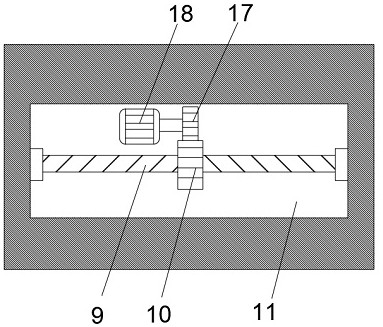

[0021] Figure 1 to Figure 3 As shown, it involves a new type of non-ferrous metal processing fixture, including a base 1; the upper surface of the base 1 is fixedly connected with an operation table 2, and the inside of the operation table 2 is provided with a cavity 11, and the cavity The inside of the cavity 11 is provided with a threaded rod 9, and the two ends of the threaded rod 9 are respectively connected in rotation with the two inner side walls of the cavity 11, and the inner bottom wall of the cavity 11 is fixedly connected with a motor 18, the motor 18 The driving end is fixedly sleeved with a driving gear 17, and the middle part of the outer surface of the threaded rod 9 is fixedly sleeved with a driven gear 10, and the driving gear 17 is meshed with the driven gear 10, and the outer surface of the threaded rod 9 Two moving rods 12 are threaded, and the two moving rods 12 are located on both sides of the driven gear 10 respectively. The top ends extend to the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com