Separation device in astragalus polysaccharide extraction process

A technology of extraction process and separation device, which is applied in the direction of manufacturing tools, presses, grain processing, etc., and can solve the problem of waste of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

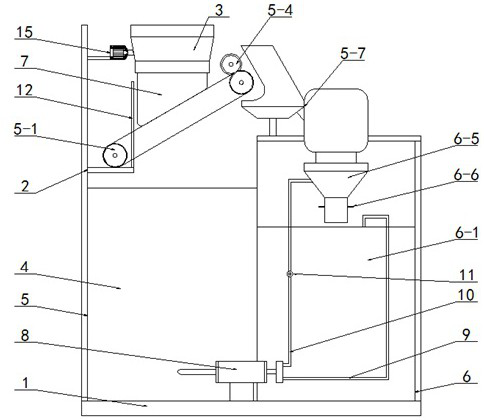

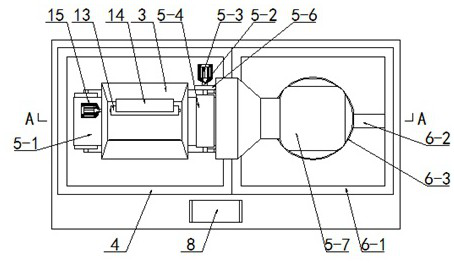

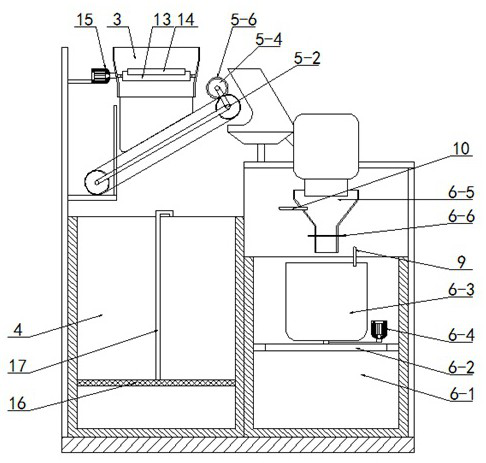

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

[0025] see as Figure 1-Figure 5 As shown, this specific embodiment comprises a base 1, a support 2, an extrusion crushing assembly 5, and a centrifugal dehydration assembly 6, wherein the base 1 is riveted with a support 2, and the extrusion crushing assembly 5 is riveted on the support 2, and the extrusion crushing A feed hopper 3 is arranged above the inlet end of the component 5, and the feed hopper 3 is riveted on the support 2, and a No. 1 liquid collection pool 4 is arranged below the extrusion crushing assembly 5, and the No. 1 liquid collection pool 4 is riveted on the On the base 1; a centrifugal dehydration assembly 6 is riveted on the base 1, and the centrifugal dehydration assembly 6 is arranged below the outlet end of the extrusion crushing assembly 5;

[0026] Described extrusion crushing assembly 5 comprises conveyer belt 5-1, squeeze roller 5-4, No. 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com