Automatic unhooking method for factory and mine railways

An automatic and railway technology, applied in railway couplings, railway car body parts, railway traffic management, etc., can solve problems such as easy operation errors, safety accidents, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

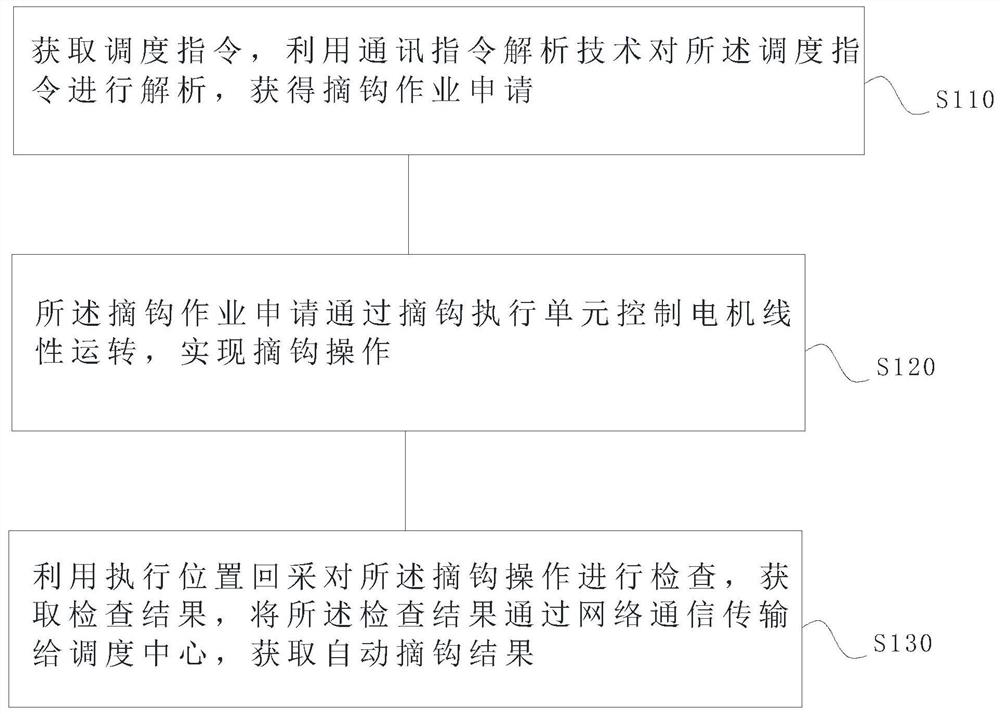

[0050] Such as figure 1 Shown, a kind of factory mine railway automatic unhooking method comprises the following steps:

[0051] S110. Obtain a scheduling instruction, analyze the scheduling instruction by using communication instruction analysis technology, and obtain an unhooking operation application;

[0052] S120, the unhooking operation application controls the linear operation of the motor through the unhooking execution unit to realize the unhooking operation;

[0053] S130. Check the unhooking operation by using the back-picking at the execution location, obtain the inspection result, transmit the inspection result to the dispatching center through network communication, and obtain the automatic unhooking result.

[0054] According to Embodiment 1, it can be seen that firstly, the dispatching instruction is obtained, and the dispatching instruction is analyzed by using the communication instruction analysis technology to obtain the unhooking operation application; th...

Embodiment 2

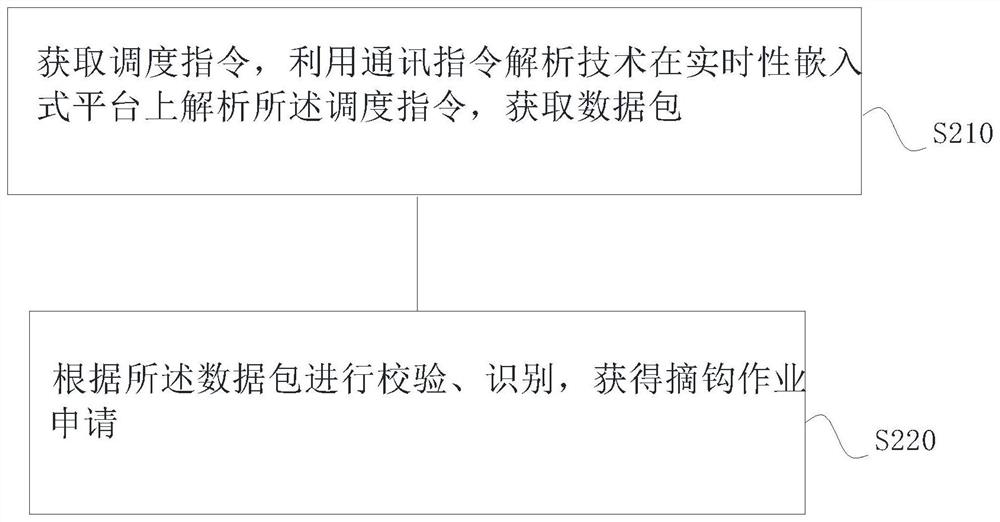

[0056] Such as figure 2 Shown, a kind of factory and mine railway automatic unhooking method comprises:

[0057]S210. Obtain a scheduling instruction, analyze the scheduling instruction on a real-time embedded platform by using communication instruction analysis technology, and obtain a data packet;

[0058] S220. Perform verification and identification according to the data packet, and obtain an unhooking operation application.

[0059] According to Embodiment 2, it can be seen that firstly, the dispatching instruction can be received through the RJ45 network interface, and the dispatching instruction can be analyzed on the real-time embedded platform by using the communication instruction analysis technology to obtain the data packet, verify and identify it according to the data packet, and obtain the unhooking operation application , this method can realize the unhooking automation of locomotive transportation in factories and mines, improve production efficiency and redu...

Embodiment 3

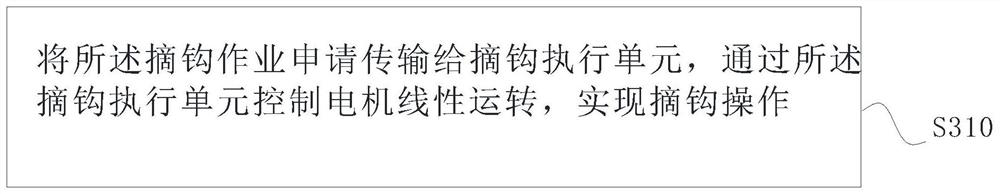

[0061] Such as image 3 Shown, a kind of factory and mine railway automatic unhooking method comprises:

[0062] S310. Transmit the unhooking operation application to the unhooking execution unit, and control the linear operation of the motor through the unhooking execution unit to realize the unhooking operation.

[0063] In Embodiment 3, first, the unhooking operation application is transmitted to the unhooking execution unit, and the linear operation of the motor is controlled by the unhooking execution unit to meet the requirements of smooth, smooth and fast unhooking, and the unhooking operation is smoothly realized. This method can realize Factory mine locomotive transport unhook automation, improve production efficiency, reduce safety accidents.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com