Ship anchor chock quick positioning method

A positioning method and anchor technology, which are applied in ship construction, ship design, ship parts, etc., can solve the problems of high time cost, many repeated measurement operations, low accuracy, etc., to solve the waste of man-hours and labor, improve Anchor platform positioning efficiency, saving man-hours and manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

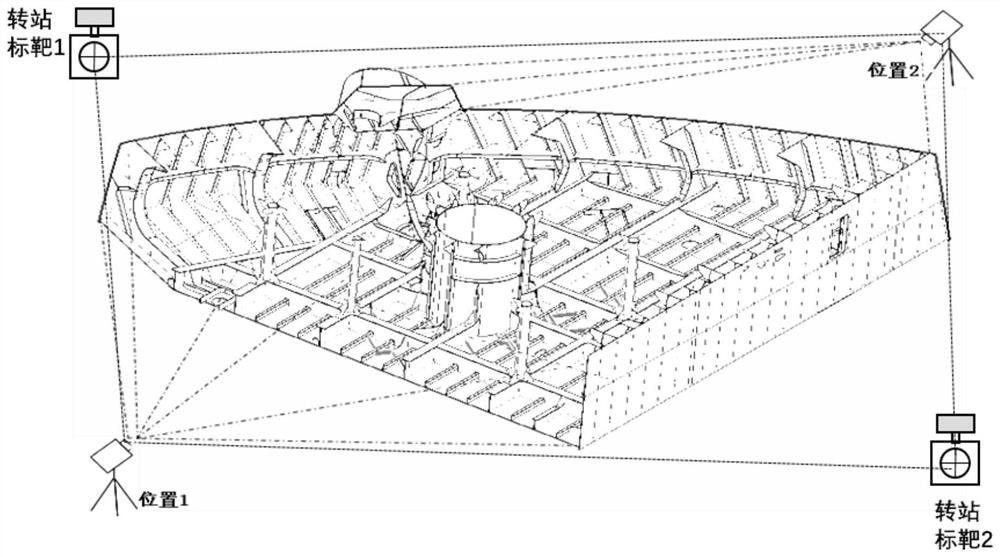

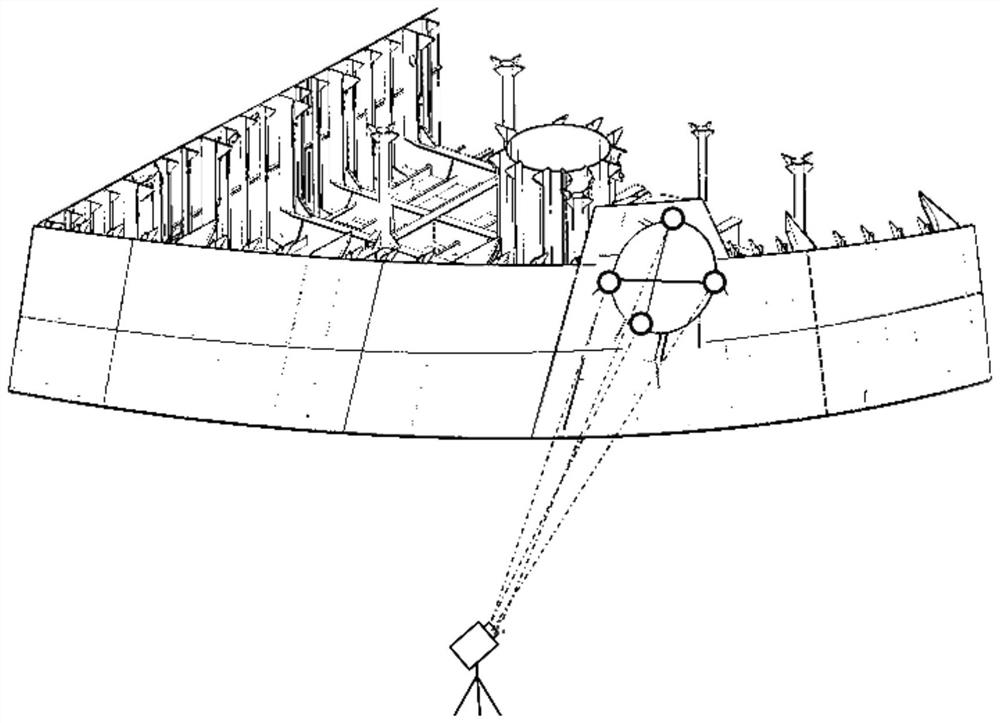

[0019] see Figure 1-2 , the present embodiment provides a fast positioning method for ship anchorage, including the following steps:

[0020] T1. Pre-weld accuracy control of the anchor system segmented: according to the general segmental accuracy control process, the accuracy status before welding is monitored to ensure that the pre-weld accuracy reaches a qualified state;

[0021] T2. Sticking of fixed transfer station patches: in the direction of the anchor platform of the anchor system section, find the location for pasting the patches, and firmly paste the transfer station patches, so that the transfer station patches are clearly visible before and after the transfer station and before the completion of the section ;

[0022] T3. Coarse positioning measurement of the anchor platform before welding: After the measurement of the segmented structural surface of the anchor system is completed, the fixed transfer station patch is used to carry out the transfer station operat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com