A kind of low-shrinkage beautifying agent and preparation method thereof

A beautifying agent and low-shrinkage technology, applied in the field of low-shrinking beautifying agent and its preparation, can solve the problems of low solid content of the beautifying agent, influence of the strength of the caulking surface, waste of manpower and material resources, etc. High acid and alkali resistance, good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

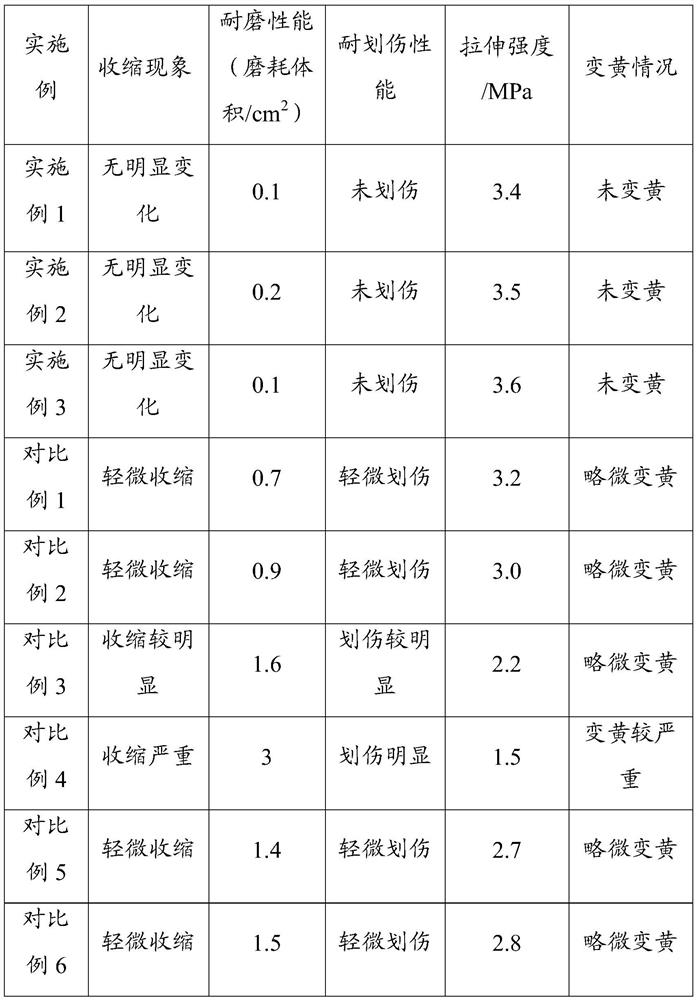

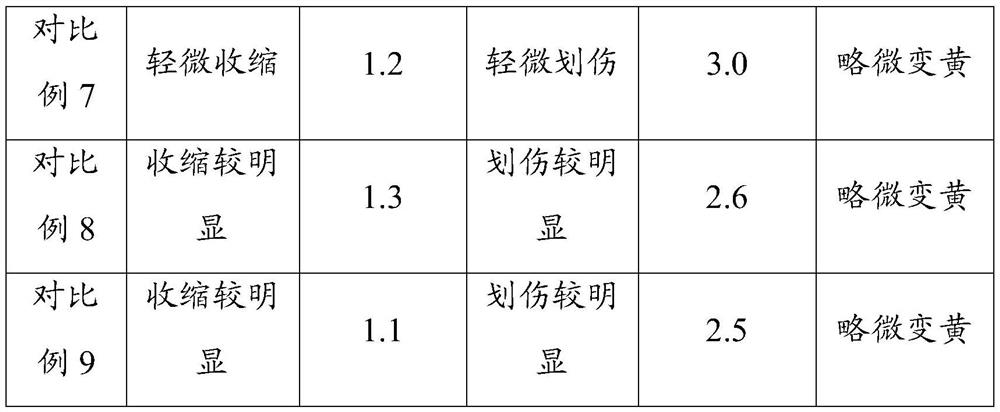

Examples

preparation example Construction

[0037] A second aspect of the present invention also provides a method for preparing the above-mentioned low-shrinkage beautifying agent, comprising the following steps:

[0038] S1: Mix N,N-dimethylformamide, nano-titanium oxide A, catalyst and ethylene glycol diglycidyl ether (mass ratio is 10:3:2:4), react at 120~150℃, Then the reaction material is cooled and centrifuged to obtain solid-phase vacuum drying to obtain nano-titanium oxide B;

[0039] S2: place nano titanium oxide B and 4,4'-diaminodicyclohexylmethane and diethyl maleate in a reaction flask to react (diethyl maleate and 4,4'-diaminodicyclohexyl The molar ratio of methane is 1.8:1, and the amount of nano-titanium oxide B added is 1.6% of the total mass of diethyl maleate and 4,4'-diaminodicyclohexylmethane). Reaction at 85°C for 18-22h to obtain nano-titanium oxide B-modified polyaspartate;

[0040] S3: adding nano-titanium oxide B modified polyaspartate, pigments and fillers, anti-wear agent, dispersant, and ...

Embodiment 1

[0049] Embodiment 1 provides a low-shrinkage beautifying agent, including a resin component and a curing agent component; the resin component, in parts by weight, includes 76 parts of nano-titanium oxide B-modified polyaspartate, 20 parts of pigments and fillers, 1 part of anti-wear agent, 2 parts of dispersant, and 1 part of defoamer; the curing agent component is aliphatic isocyanate; the volume ratio of the resin component and the curing agent component is 2:1 .

[0050] The nano-titanium oxide A is DK405-1, manufacturer: Beijing Dekedao Gold Technology Co., Ltd.

[0051] The pigment and filler is a mixture of titanium dioxide with oil absorption of 15%, titanium dioxide with oil absorption of 18%, and titanium dioxide with oil absorption of 21%, wherein the mass ratio of the three is 1:1.2:1.4.

[0052] The dispersant is a mixture of ethylene glycol monobutyl ether and BYK110 dispersant, and the mass ratio is 0.8:1.

[0053] The curing agent component, in parts by weight...

Embodiment 2

[0060] Embodiment 2 provides a low-shrinkage beautifying agent, including a resin component and a curing agent component; the resin component, in parts by weight, includes 85 parts of nano-titanium oxide B-modified polyaspartate, 8 parts of pigment and filler, 2 parts of anti-wear agent, 3 parts of dispersant, 2 parts of defoamer; the curing agent component is aliphatic isocyanate; the volume ratio of the resin component and the curing agent component is 1:2 .

[0061] The nano-titanium oxide A is DK40-2, manufacturer: Beijing Dekedao Gold Technology Co., Ltd.

[0062] The pigment and filler is a mixture of titanium dioxide with oil absorption of 15%, titanium dioxide with oil absorption of 18%, and titanium dioxide with oil absorption of 21%, wherein the mass ratio of the three is 1:1.5:1.7.

[0063] The dispersant is a mixture of ethylene glycol monobutyl ether and BYK110 dispersant, and the mass ratio is 1:1.2.

[0064] The curing agent component, in parts by weight, incl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com