Textile machine reed with reed width adjusting function and reed width adjusting method of textile machine reed

An adjustable and machine-made reed technology, which is applied in textiles, textiles, papermaking, weaver tools, etc., can solve the problems of user inconvenience, the reed does not have reed width adjustment, and the reed height cannot be adjusted, so as to achieve convenience The effect of using and increasing the length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

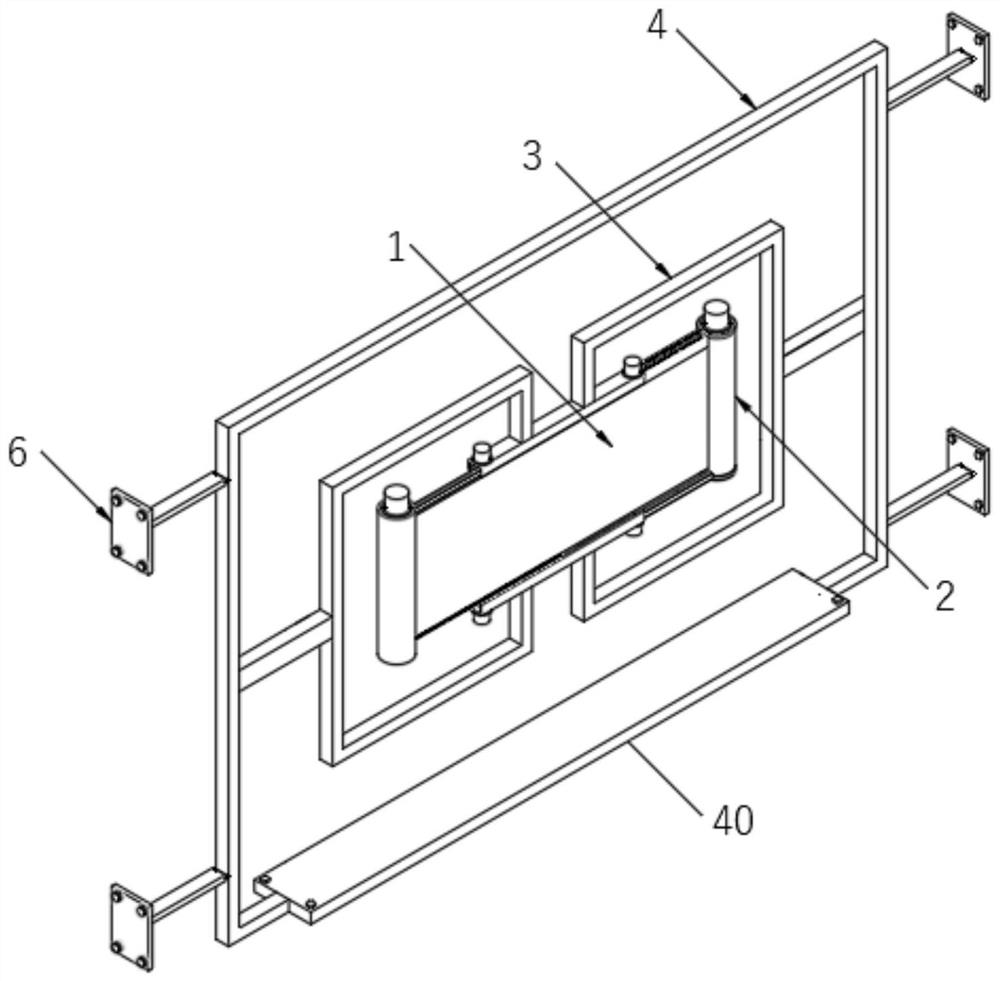

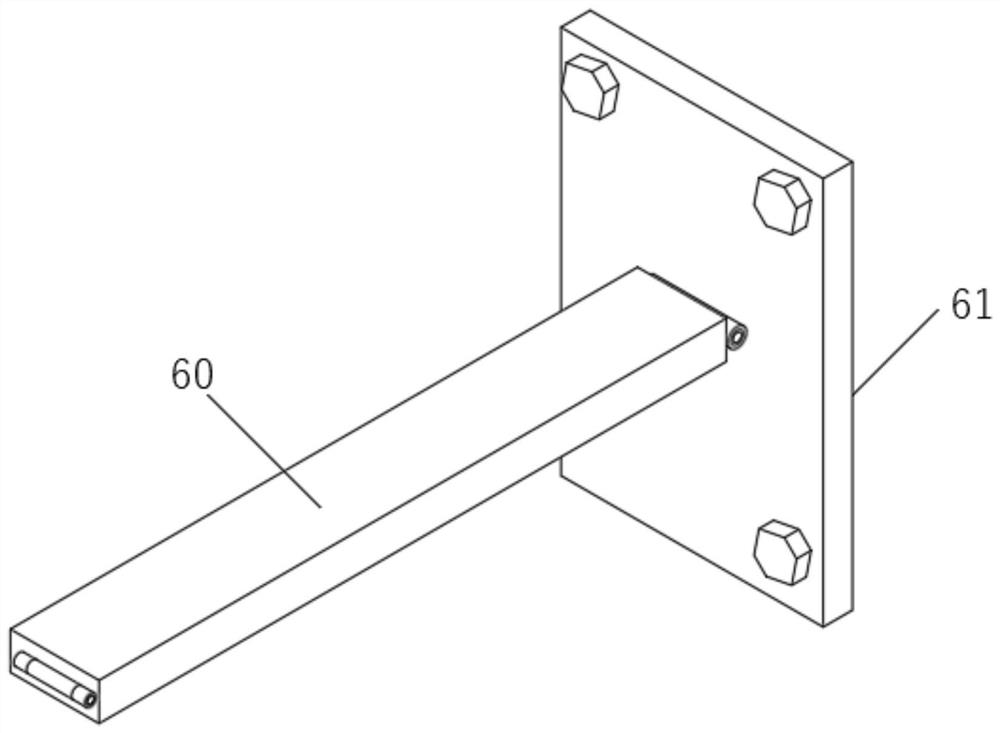

[0045] see Figure 1-Figure 9 , the present embodiment proposes a textile machine reed with adjustable reed width, comprising a reed main body 1, on which a reed width adjustment device 2 is arranged, and the reed width adjustment device 2 includes two upper and lower mutually positive The pair of fixed guide rails 20 and two left and right reeling drums 23 facing each other are provided with a mounting groove 201 communicating with the outside world in the fixed guide rail 20. The cross section of the mounting groove 201 is U-shaped, and the reeling drum 23 is tightly welded with Two upper and lower fixed strips 22 that are centrally symmetrical, the fixed strips 22 are located in the installation groove 201 and are slidably connected with the installation groove 201. Specifically, the front and rear sides of the installation groove 201 are provided with grooves along the installation groove 201. The chute 202 arranged in the length direction, the side of the fixed bar 22 fac...

Embodiment 2

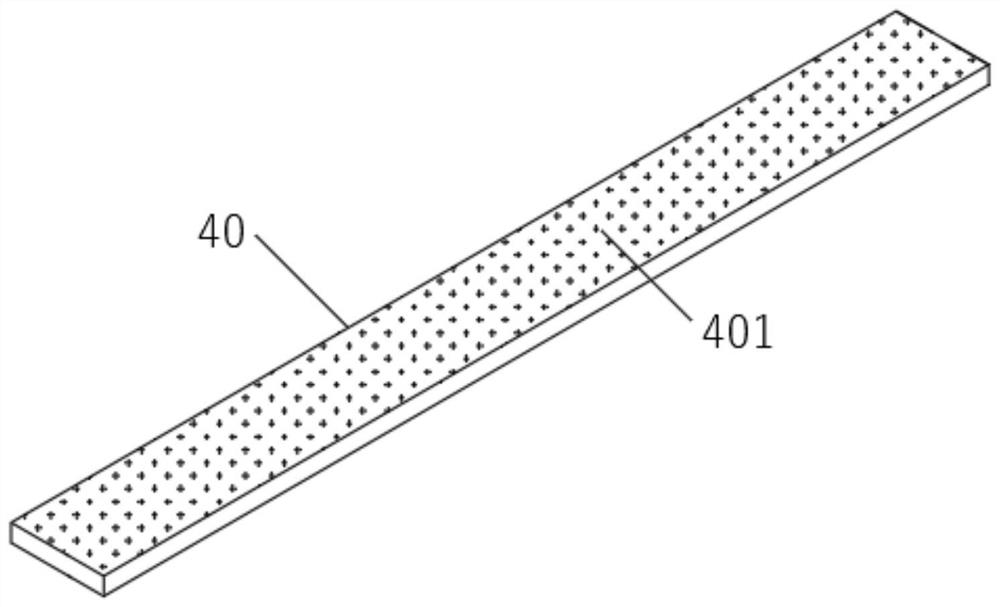

[0052] see Figure 10-Figure 11 , a kind of textile machine reed with adjustable reed width that the present embodiment proposes also includes two height adjustment devices 5, and two height adjustment devices 5 are arranged between the external fixing frame 3 and the support frame 4, and the height adjustment device 5 includes two drive motors 50 that are symmetrical to each other and fixedly installed on the fixed base plate 40 and two guide rods 52 that are symmetrical to each other and fixedly installed on the fixed base plate 40. The fixed base on the drive motor 50 is fixed by a plurality of fastening bolts Installed on the fixed base plate 40, the guide rod 52 is tightly welded on the fixed base plate 40, the output shaft of the drive motor 50 is arranged vertically upward, and the end of the output shaft of the drive motor 50 is tightly welded with a screw mandrel 51 arranged vertically upward, The screw mandrel 51 passes through the corresponding rectangular block 30 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com