A car interior handle and its manufacturing method

A manufacturing method and automobile technology, applied in vehicle locks, building structures, lock applications, etc., can solve the problems of easily affecting the comfort, aggravating the wear and tear of the inner handle, and affecting the service life of the inner handle, so as to improve the strength of the handle and improve the Effect of service life and loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

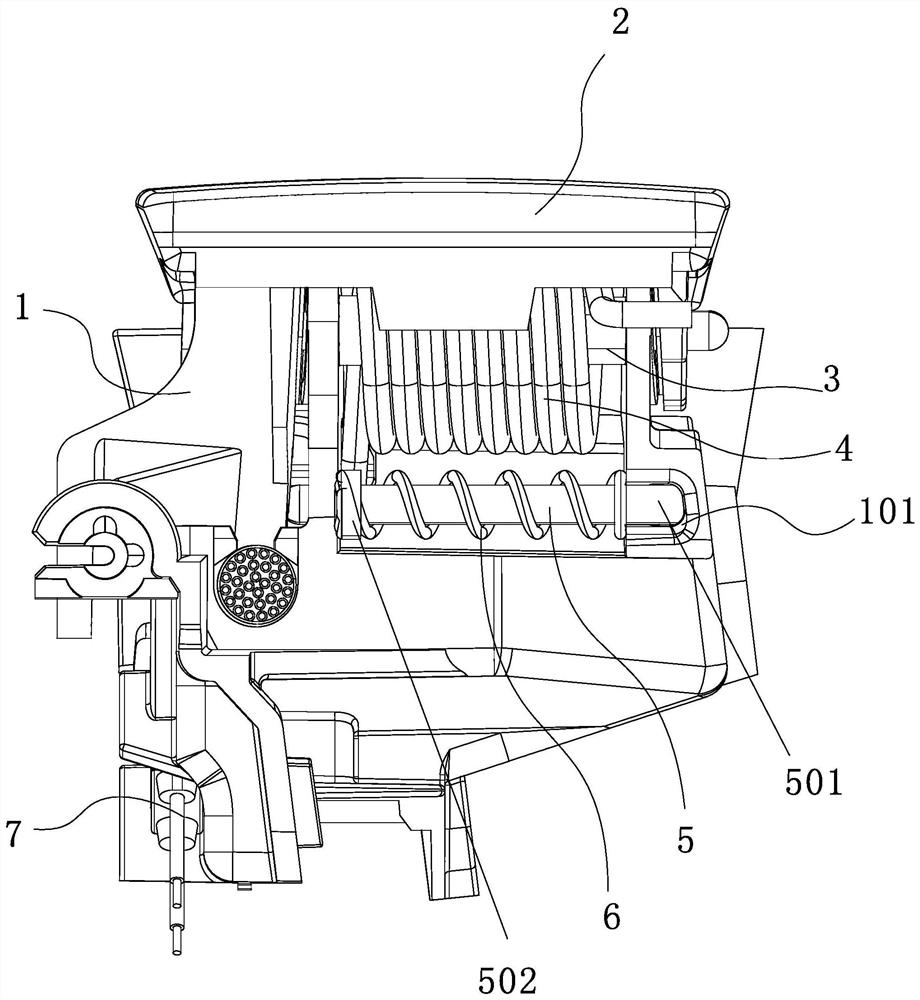

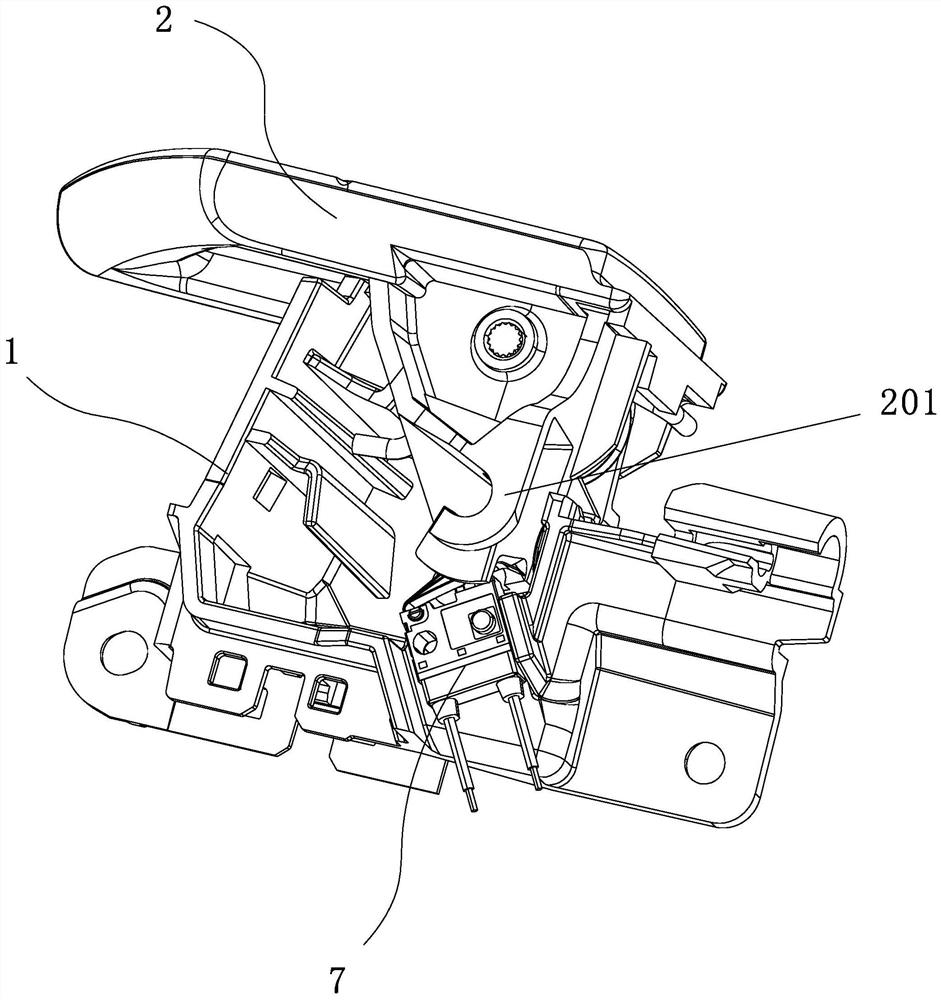

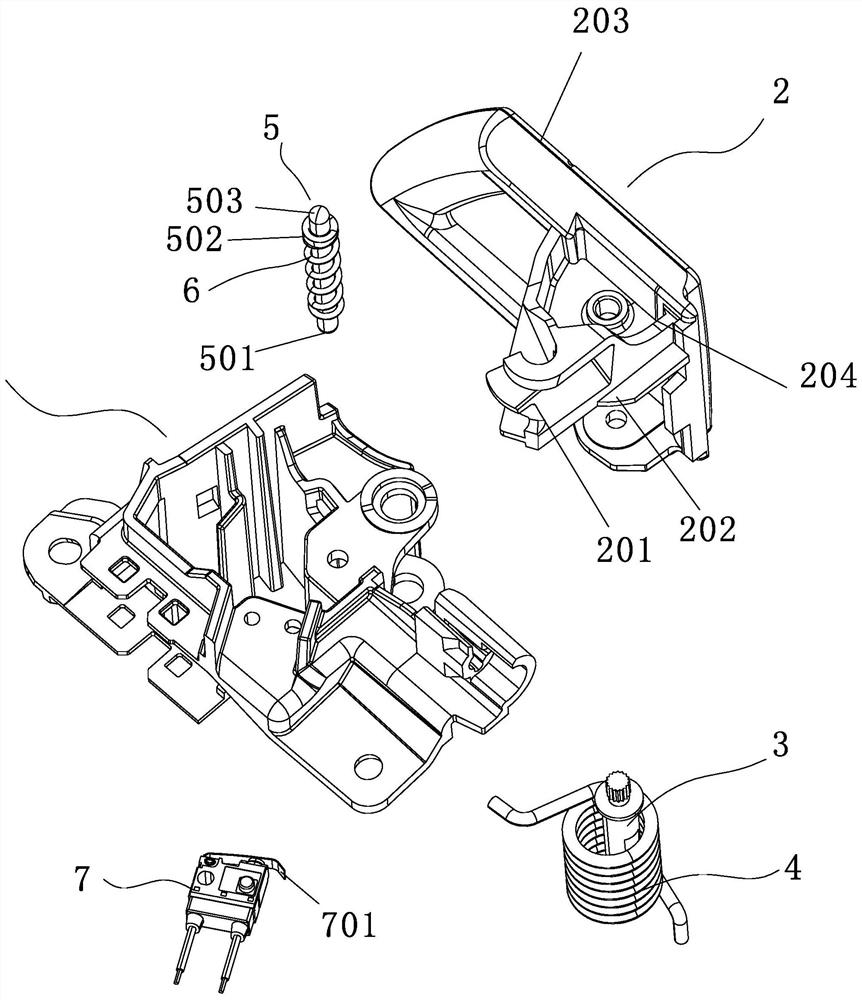

[0032] Such as figure 1 , figure 2 , image 3 In the shown embodiment 1, a kind of car inner opening handle includes a handle base 1 and a handle 2, the handle base 1 fixes the inner handle bracelet on the door, and a micro switch 7 is arranged on the handle base 1, wherein the micro switch 7 The switch 7 adds the function of an electronic lock to the inner pull bracelet, and the micro switch 7 is provided with a shrapnel 701, the shrapnel 701 contacts the handle 2 and then transmits signals to control the opening and closing of the electronic lock, and the handle 2 is used to trigger the electronic lock and the mechanical lock. Lock, the handle 2 is rotatably connected to the handle base 1, a rotating shaft 3 is arranged between the handle 2 and the handle base 1, and a second return spring 4 that drives the handle 2 to rotate and reset is arranged outside the rotating shaft 3; in addition, the handle base 1 A limit plunger 5 is also arranged on the top, and the limit plun...

Embodiment 2

[0037] Embodiment 2 is a method for manufacturing an interior handle of an automobile, comprising the following steps:

[0038] Step 1: Firstly, the connecting inner part 204 is injection-molded through an injection mold, wherein the material used for injection molding of the connecting inner part 204 is PC / ABS+GF30;

[0039] Step 2: Rotate the connecting inner 204 and its injection mold by 180 degrees, install the injection mold used for the hand-held outer 203, and inject the hand-held outer 203. The injection molding material of the hand-held outer 203 is electroplating grade PC / ABS, and then hold the hand-held outer 203 Perform electroplating to complete the manufacture of the handle 2;

[0040] Step 3: Injection molding the handle base 1;

[0041] Step 4: Install the handle 2 on the handle base 1 to complete the manufacturing of the inner handle bracelet.

[0042] In this technical solution, since the wall thickness of the handle 2 itself is relatively large, double-sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com