Air bag type testing fixture for air tightness of paper bag

An air-tight, air-bag technology, applied in the direction of using liquid/vacuum for liquid-tightness measurement, etc., can solve the problems of connection strength not reaching the design state, checking glue, affecting the carrying capacity of paper bags, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

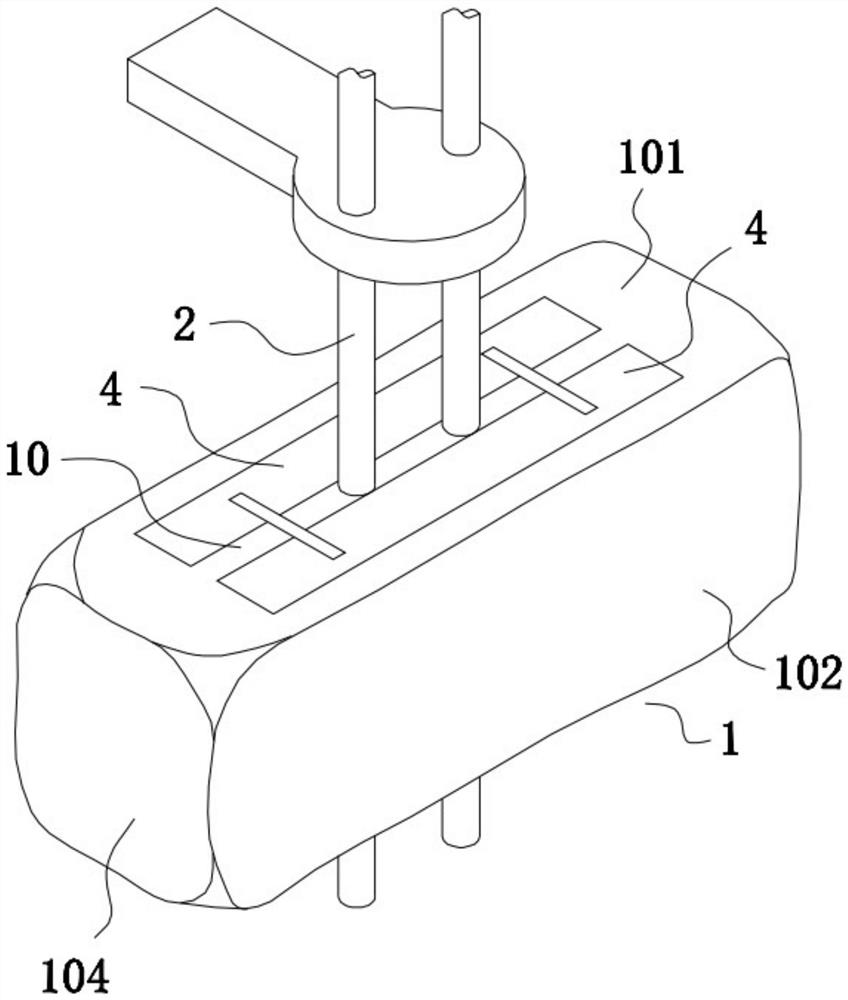

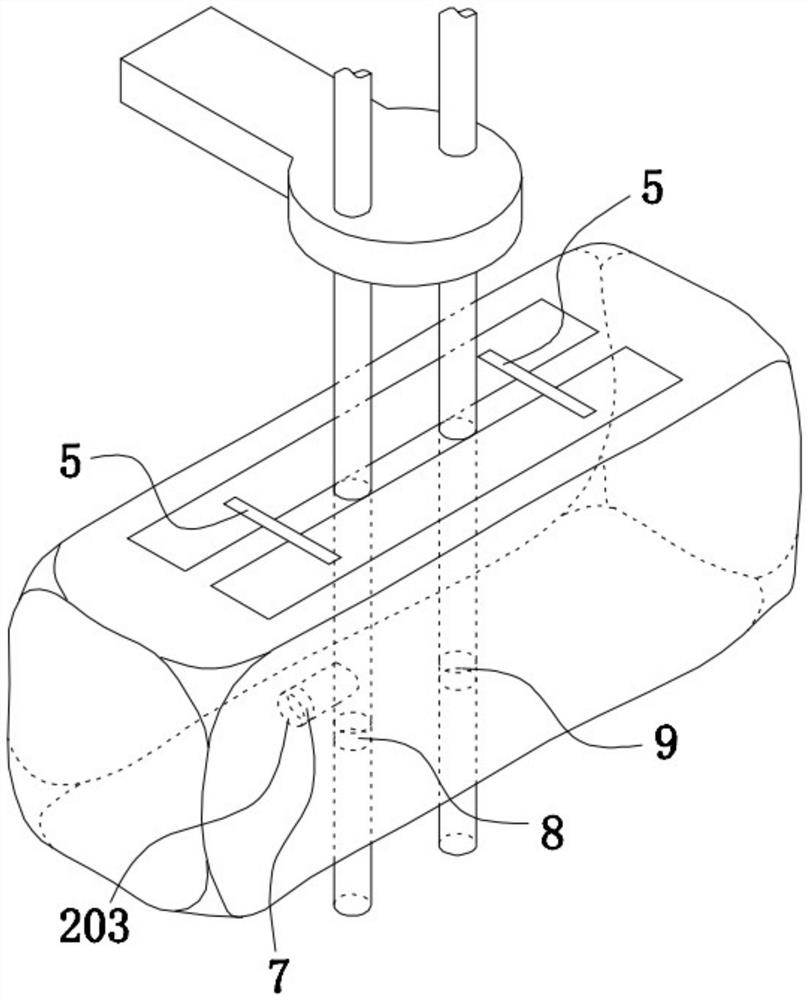

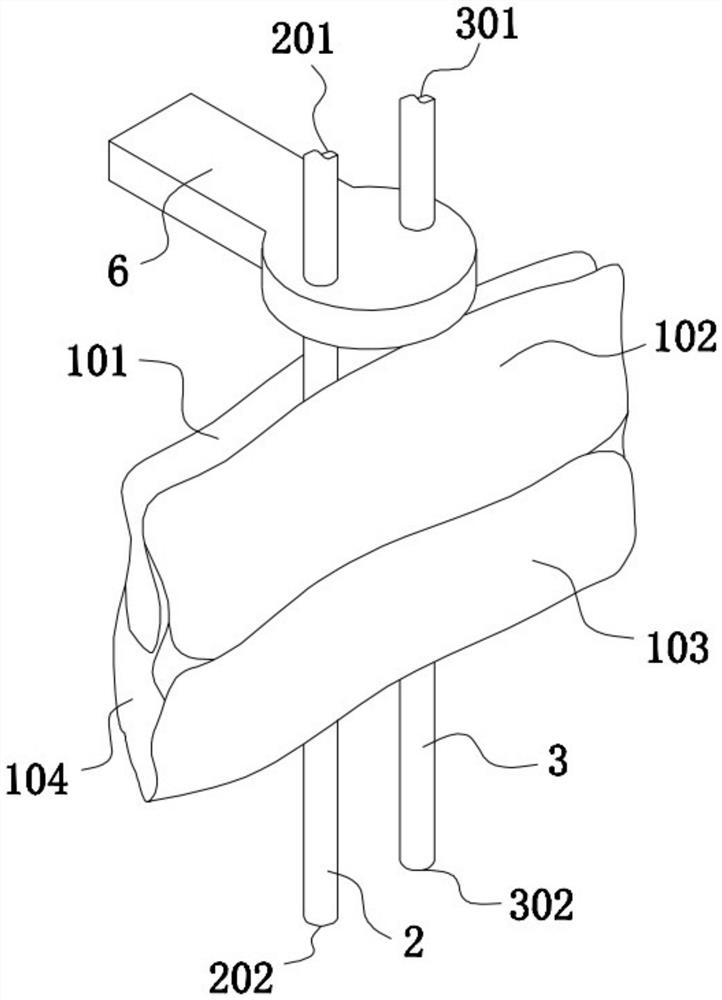

[0035] In order to achieve the purpose of the present invention, the airbag 1 is a cuboid in the stretched state, and the vertical projection profile of the airbag 1 in the stretched state matches the opening contour of the paper bag 11; When stuffed into the paper bag 11, both ends of the air inlet pipe 2 include a first air inlet 201 outside the paper bag 11 and a first air outlet 202 inside the paper bag 11. The air port 203, the inner air outlet 203 is connected with the first air valve 7, the first air outlet 202 is connected with the second air valve 8; the first air inlet 201 is connected with an air compressor, the first air valve 7, the second air valve 8 It is a self-operated pressure control valve. The first air valve 7 and the second air valve 8 are two-way valves and one-way valves respectively. The pressure required to open the second air valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com