High-precision clamping type telescopic system

A telescopic system and high-precision technology, which is applied in the field of high-precision cassette telescopic systems, can solve problems such as unstable precision and large design volume, reduce design volume and weight, ensure assembly accuracy, and ensure optical The effect of image quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

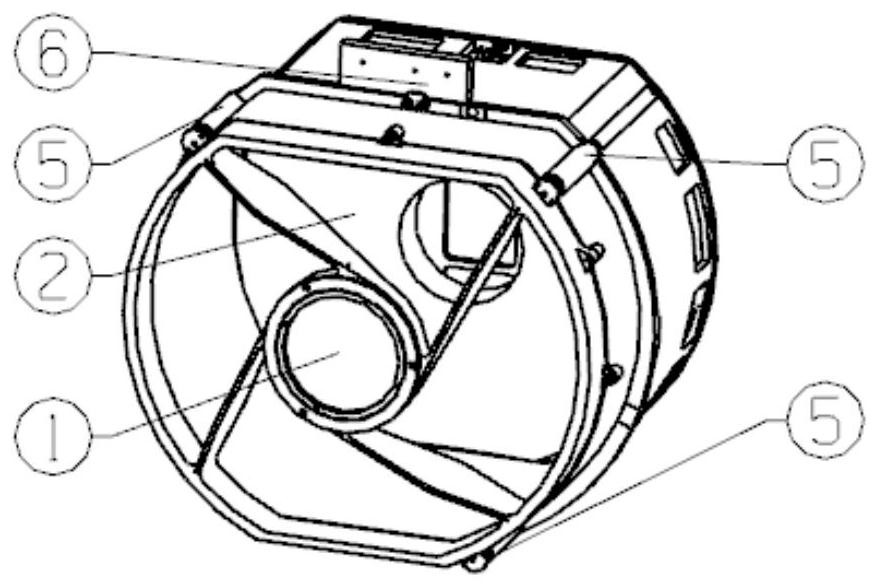

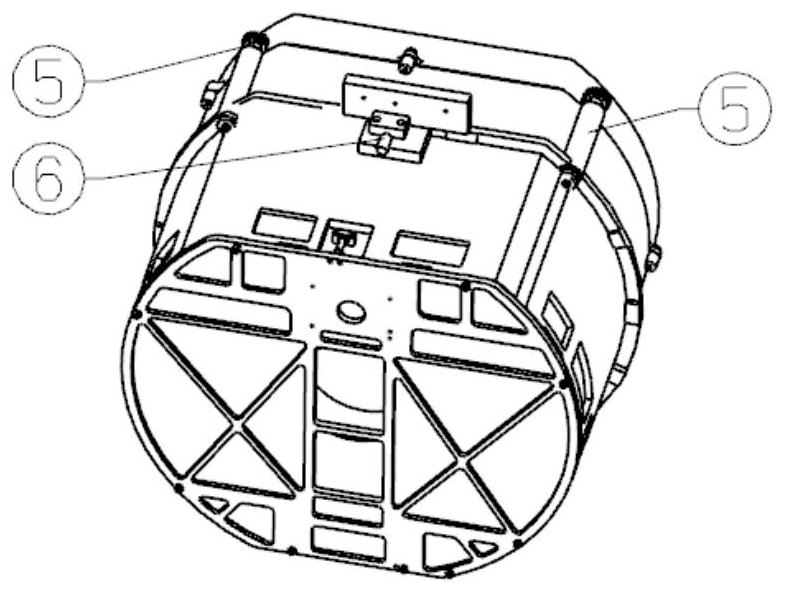

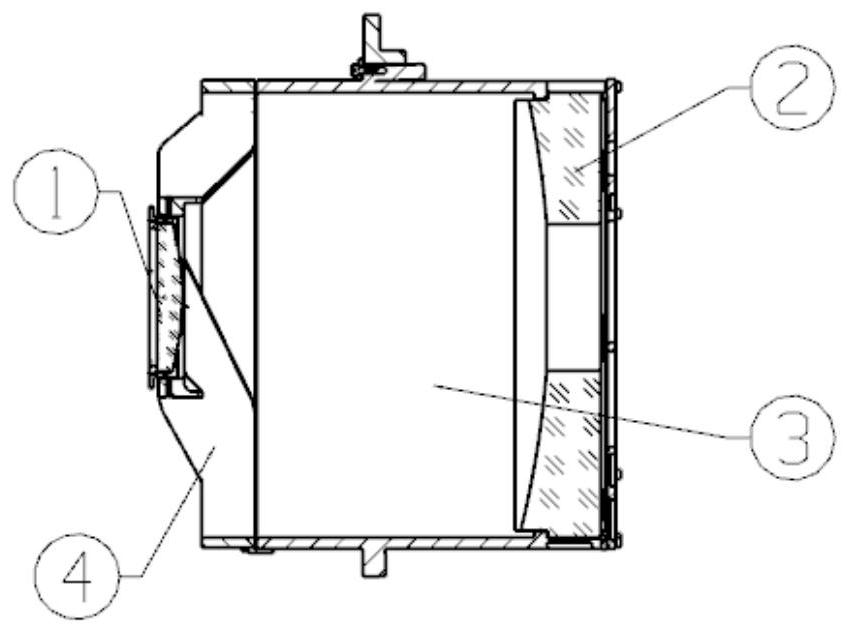

[0031] Such as figure 1 As shown, the card type telephoto optical system includes two lenses, which are respectively a secondary mirror 1 and a primary mirror 2 from front to back. Correspondingly, as figure 1 , figure 2 , image 3 As shown, the card type telescopic system of the present invention includes: a primary mirror part 3 , a secondary mirror part 4 , a secondary mirror position adjustment mechanism 5 and an external mounting mechanism 6 .

[0032] Figure 4 Primary mirror part 3 is shown. The main mirror component 3 mainly includes a main mirror 2 , a main mirror fixing mechanism 7 , a main mirror mounting seat 8 , and a main mirror rear seat 9 . Figure 5 It mainly shows the main mirror 2, the main mirror fixing mechanism 7, and the main mirror rear seat 9, among which, the main mirror 2 is surrounded by processing flanges for the main mirror in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com