Waterproof women's boots and preparation process thereof

A preparation process and a technology for waterproof finishing, applied in the field of shoes, can solve the problems of poor waterproof effect, affecting wearing experience, wet boots, etc., and achieve the effects of improving waterproof effect, improving waterproof performance, and improving the degree of dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

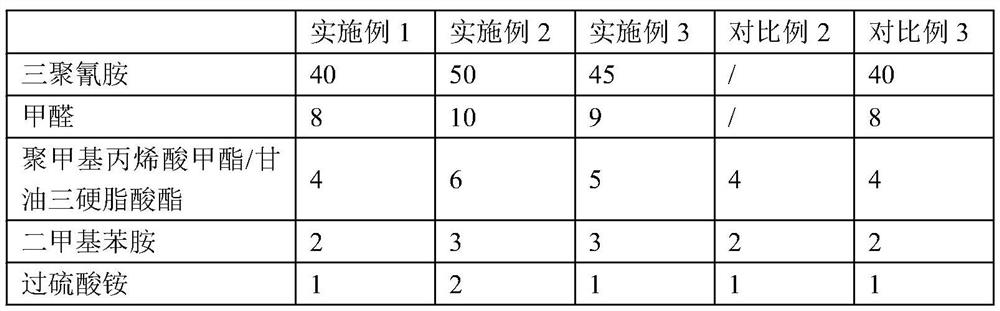

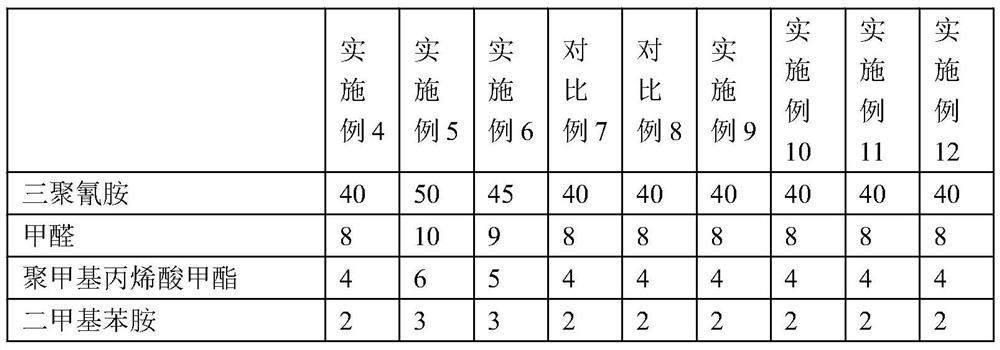

Embodiment 1

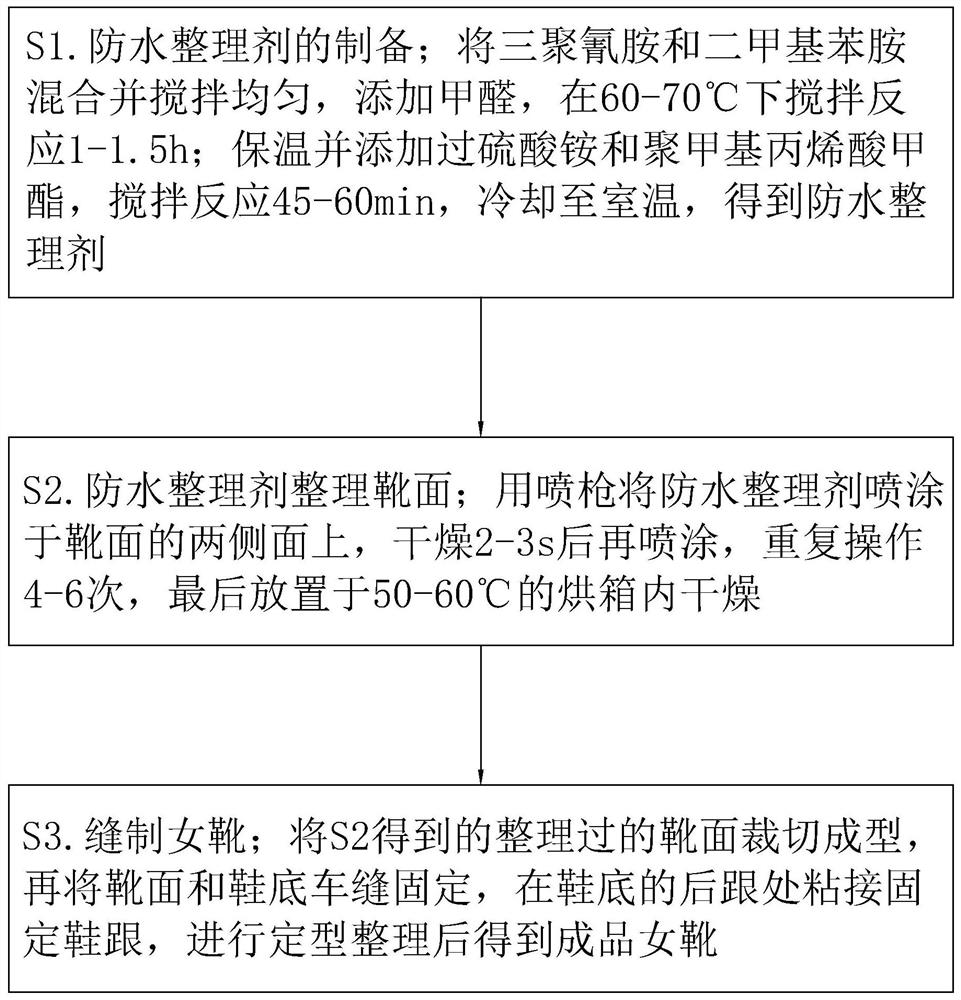

[0036] This application discloses a waterproof women's boot and its preparation process. The women's boot includes a boot upper and a sole. Refer to figure 1 , the preparation process includes the following steps:

[0037] S1. Preparation of waterproof finishing agent; mix melamine and dimethylaniline and stir evenly, add formaldehyde, stir and react at 60°C for 1 hour; keep warm and add ammonium persulfate and polymethyl methacrylate, stir and react for 45 minutes, and cool to room temperature to obtain a waterproof finishing agent;

[0038] S2. Finish the boot surface with a waterproof finishing agent; spray the waterproof finishing agent on both sides of the boot surface with a spray gun, spray after drying for 2 seconds, repeat the operation 4 times, and finally place it in an oven at 50°C to dry;

[0039] S3. Sewing women's boots; cut and shape the sorted boot uppers obtained in S2, then sew and fix the boot uppers and soles, glue and fix the heels at the heels of the so...

Embodiment 2

[0042] This application discloses a waterproof women's boot and its preparation process. The women's boot includes a boot upper and a sole. Refer to figure 1 , the preparation process includes the following steps:

[0043] S1. Preparation of waterproof finishing agent; mix melamine and dimethylaniline and stir evenly, add formaldehyde, stir and react at 70°C for 1.5h; keep warm and add ammonium persulfate and polymethyl methacrylate, stir and react for 60min, Cool to room temperature to obtain a waterproof finishing agent;

[0044] S2. Finish the boot surface with a waterproof finishing agent; spray the waterproof finishing agent on both sides of the boot surface with a spray gun, spray after drying for 3 seconds, repeat the operation 6 times, and finally place it in an oven at 60°C to dry;

[0045] S3. Sewing women's boots; cut and shape the sorted boot uppers obtained in S2, then sew and fix the boot uppers and soles, glue and fix the heels at the heels of the soles, and ob...

Embodiment 3

[0048] This application discloses a waterproof women's boot and its preparation process. The women's boot includes a boot upper and a sole. Refer to figure 1 , the preparation process includes the following steps:

[0049] S1. Preparation of waterproof finishing agent; mix melamine and dimethylaniline and stir evenly, add formaldehyde, stir and react at 68°C for 1.5h; keep warm and add ammonium persulfate and polymethyl methacrylate, stir for 52min, Cool to room temperature to obtain a waterproof finishing agent;

[0050] S2. Finish the boot surface with a waterproof finishing agent; spray the waterproof finishing agent on both sides of the boot surface with a spray gun, spray after drying for 3 seconds, repeat the operation 5 times, and finally place it in an oven at 55°C to dry;

[0051] S3. Sewing women's boots; cut and shape the sorted boot uppers obtained in S2, then sew and fix the boot uppers and soles, glue and fix the heels at the heels of the soles, and obtain finis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com