Diamond wire tension adjusting mechanism

A technology of tension adjustment and diamond wire, which is applied in the direction of manufacturing tools, stone processing equipment, fine working devices, etc., can solve problems such as tension fluctuation, affecting cutting quality, diamond wire breakage, etc., and achieve the effect of accurate tension adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

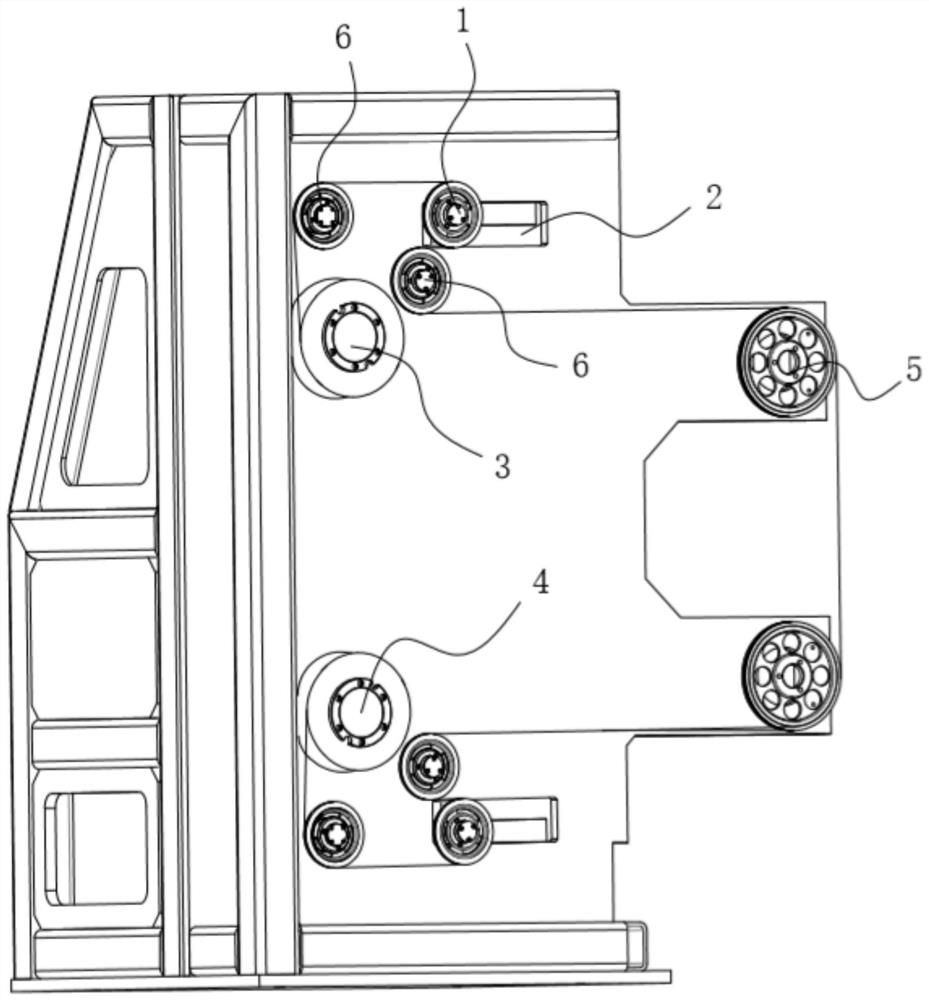

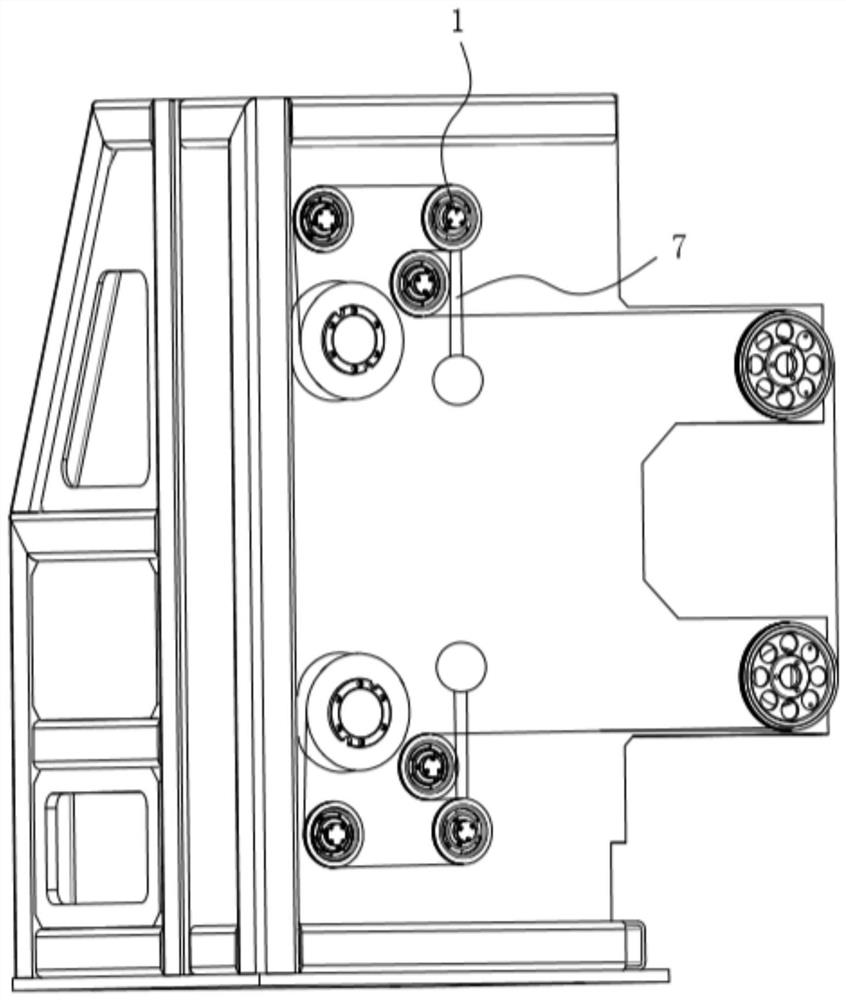

[0031] Embodiment 1: A diamond wire tension adjustment mechanism, see attached figure 1 , including a tension wheel 1 and a thrust application mechanism 2 that applies a thrust to the tension wheel 1; there are two tension wheels 1, wherein the tension wheel 1 is located at the cutting side of the take-up and pay-off roller one 3 and the side near the take-up and take-off roller one 3 Between the wheels 5, another tension wheel 1 is located between the take-up and pay-off roller two 4 and the cutting wheel 5 near the side of the take-up and take-off roller two 4; The tensile force of the diamond wire received by the tension wheel 1 and the thrust applied by the thrust applying mechanism 2 are in a straight line. When the tension applied by the diamond wire of the tension wheel 1 and the thrust are in a balanced state, they are equal in magnitude and opposite in direction; 1 can move along the straight line where the thrust is located.

[0032] Specifically, four guide wheels ...

Embodiment 2

[0045] Embodiment two: a diamond wire tension adjustment method, comprising the following steps:

[0046] Determining thrust: according to the formula Calculate the thrust F T ; Among them, F is the diamond wire tension, N; F T is the thrust of the linear motor, N; m 1 The mass of the mover of the linear motor, kg; v 1 and v 2 Respectively, the linear velocity m / min of the diamond wire on both sides of the tension wheel 1; Ff is the friction force of the linear motor, N; V line is the moving speed of the linear motor mover, m / min;

[0047] Apply thrust: according to the calculated thrust, apply a constant thrust to the tension wheel (1) through the linear motor;

[0048] Mechanism operation: During operation, when the tension exerted by the diamond wire on the tension wheel changes, the balance at the tension wheel (1) is broken, and the tension wheel (1) moves until the tension wheel (1) receives the tension until it is balanced again with the thrust exerted by the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com