Tensioning device of belt conveyor, belt conveyor and adjusting method

A technology for belt conveyors and tensioning devices, applied in conveyors, transportation and packaging, etc., can solve the problems of high cost of tensioning devices, large space occupied by equipment, and high maintenance level, so as to improve service life, occupy small area, The effect of a high maintenance level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

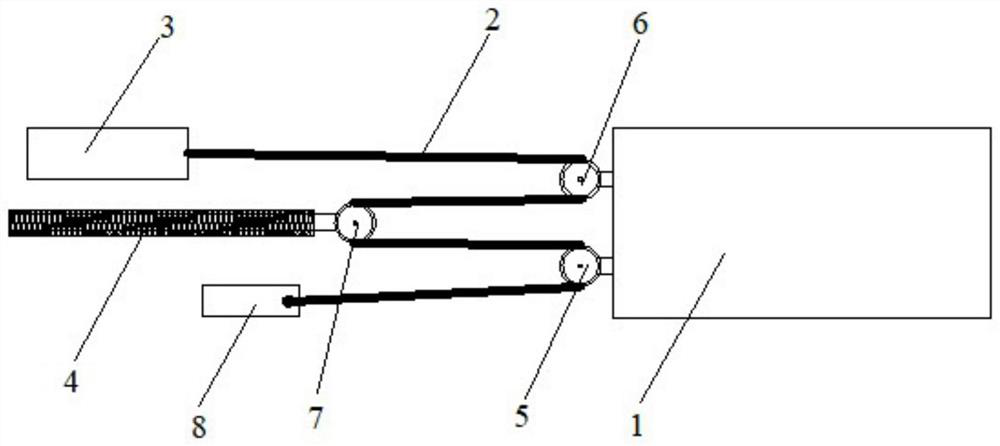

[0053] Such as figure 1 As shown, this embodiment provides a tensioning device for a belt conveyor, which includes a swimming structure 1 , an adjusting rope, a pulley block, a driving structure and an elastic telescopic structure 4 .

[0054] In this embodiment, the swimming structure 1 includes a traveling trolley and a tensioning roller, a belt is wound on the tensioning roller, and a pulley block is fixed on the traveling trolley.

[0055] The adjusting rope is a steel wire rope 2, and the driving structure is a tensioning winch 3. One end of the wire rope 2 is fixed on the frame 8 of the belt conveyor, and the other end has a longer margin, which is wound on the tensioning winch 3 to adjust the position of the traveling trolley. The tensioning winch 3 has a large tensioning stroke adjustment range, can accurately control the tensioning force, and has a stable and adjustable growth speed. In this embodiment, the JZB-6 tensioning winch 3 is selected, the diameter of the s...

Embodiment 2

[0065] This embodiment provides a belt conveyor, which includes a frame 8, a roller set, idler rollers and a belt, and also includes the tensioning device of Embodiment 1. The drum set includes a driving drum and a transmission drum, the driving drum and the driving drum are arranged on the frame 8, and the belt is wound on the drum set.

[0066] One end of the wire rope 2 of tensioner is fixed on the frame 8. Preferably, the tensioning device is arranged at the tail of the belt conveyor, and the tensioning roller is arranged on the lower belt.

Embodiment 3

[0068] This embodiment provides a method for adjusting the belt conveyor, using the tensioning device of Embodiment 1 to adjust the tension of the belt, including the following steps:

[0069] S1: Before the belt conveyor is started, the driving structure is started to shorten the steel wire rope 2, and drive the tensioning roller to tighten the belt. The elastic telescopic structure 4 is compressed during the belt tensioning process and stores elastic potential energy.

[0070] S2: When the pre-tensioning force on the belt reaches 1.3-1.5 times of the tension value during stable operation, stop the operation of the tensioning winch 3, fix the length of the wire rope 2, start the belt conveyor, and the belt is under the friction of the roller Start spinning.

[0071] S3: The belt gradually rotates to a steady state at a constant speed, and the required tension decreases and stabilizes. At the same time, the elastic telescopic structure 4 compressed in step S1 is gradually ext...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com