Flexible drawing tension slow control device for metal microwire

A tension control and fine wire technology, which is applied in the directions of transportation and packaging, conveying filamentous materials, and thin material processing. And its fluctuation control and other issues, to achieve the effect of precise adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

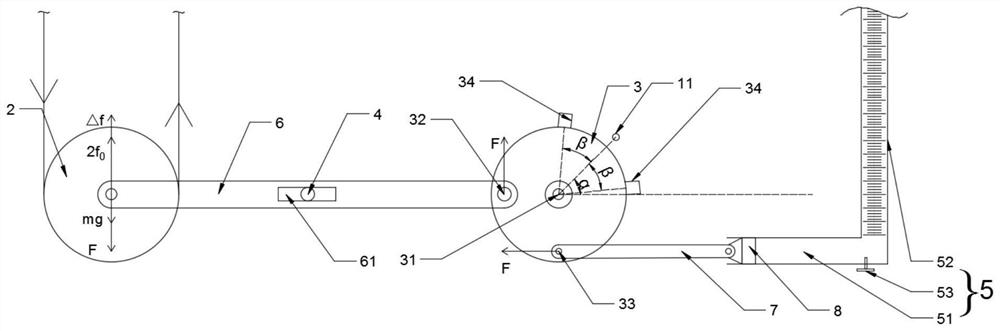

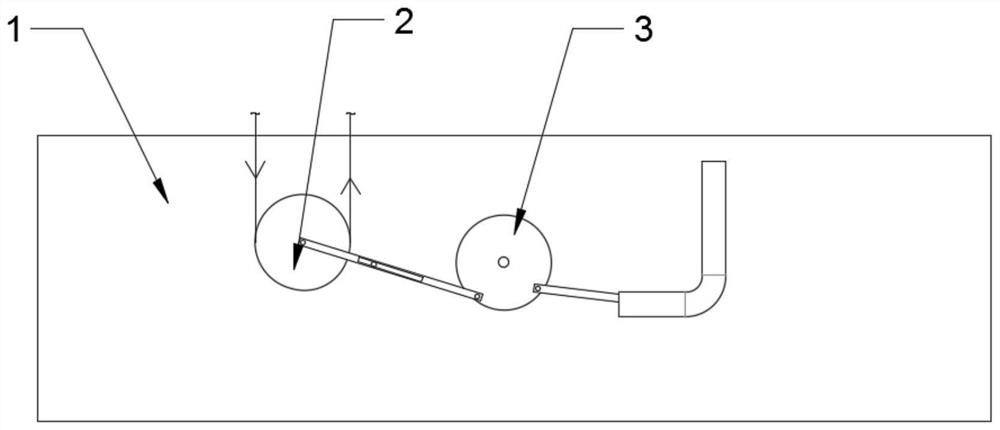

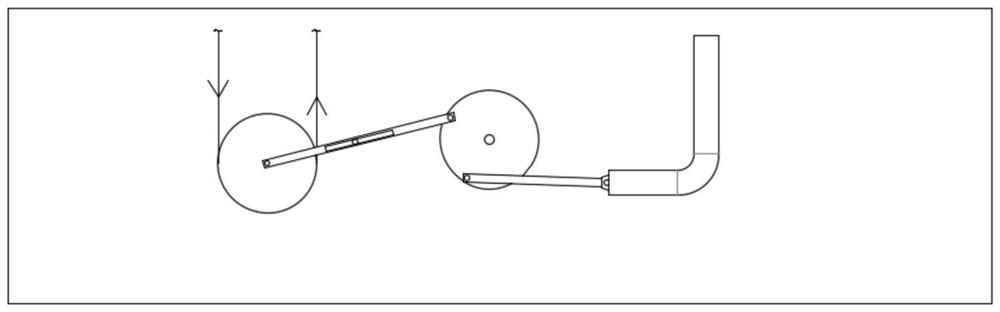

[0031] like figure 1 The shown metal fine wire drawing flexible tension control device includes a fixed side plate 1, a tension adjustment wheel 2, a rotating disc 3, a fulcrum shaft 4, a rotating disc shaft 31 and a hydraulic tube 5, and the fulcrum shaft 4 and the rotating disc shaft 31 is vertically fixed on the fixed side plate 1, the rotating disk 3 is connected to the rotating disk shaft 31 through a bearing, and a first connecting rod 6 is arranged between the tension adjusting wheel 2 and the rotating disk 3, and the first connecting rod One end is hinged with the wheel shaft of the tension adjusting wheel 2, and the other end is hinged with the edge of the rotating disk 3 near the tension adjusting wheel side. The middle part of the first connecting rod 6 is provided with a long hinged sliding hole that matches the fulcrum shaft 4. 61. The length of the hinged sliding hole 61 is greater than the diameter of the fulcrum shaft 4. The width of the hinged sliding hole 61 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com