A kind of maleopimaric acid modified silicon-phosphorus synergistic flame retardant, its preparation method and flame-retardant polyurethane foam prepared therefrom

A technology of maleopimaric acid and polyurethane foam, which is applied in the field of flame-retardant materials, can solve the problems of poor flame-retardant performance of rigid polyurethane foam, and achieve the effects of ensuring stability, high flame-retardant performance, and improving rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

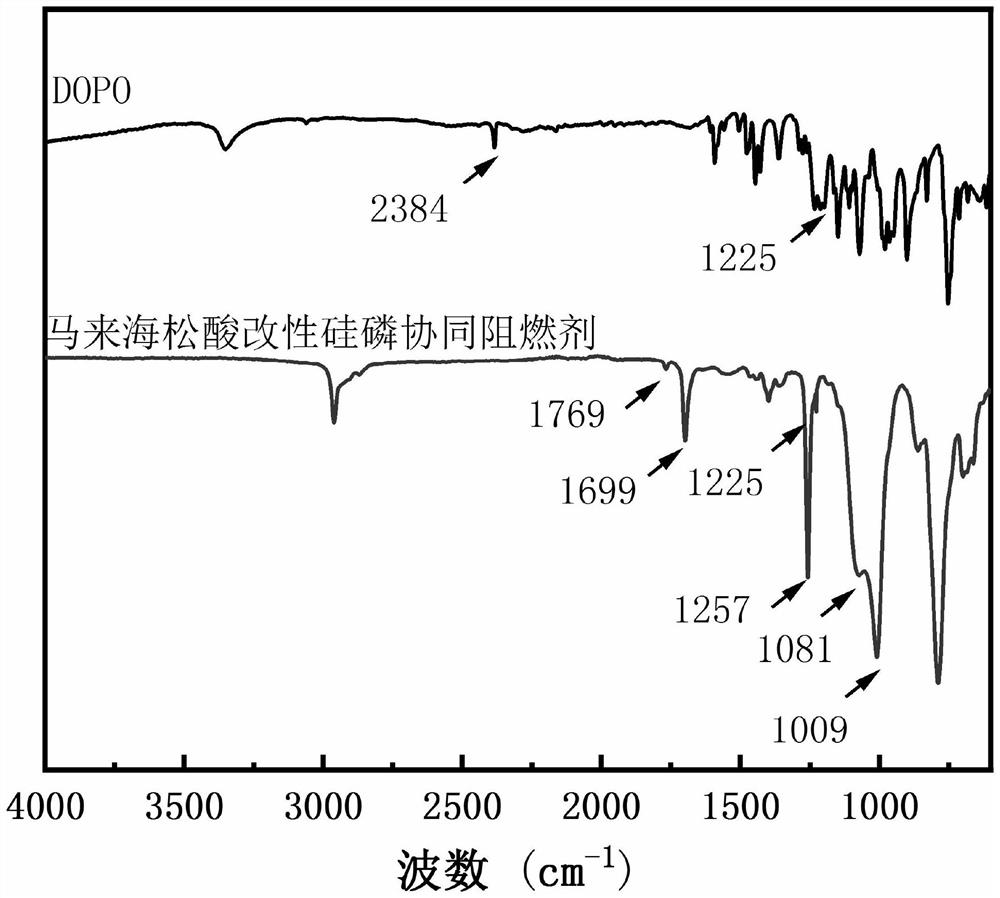

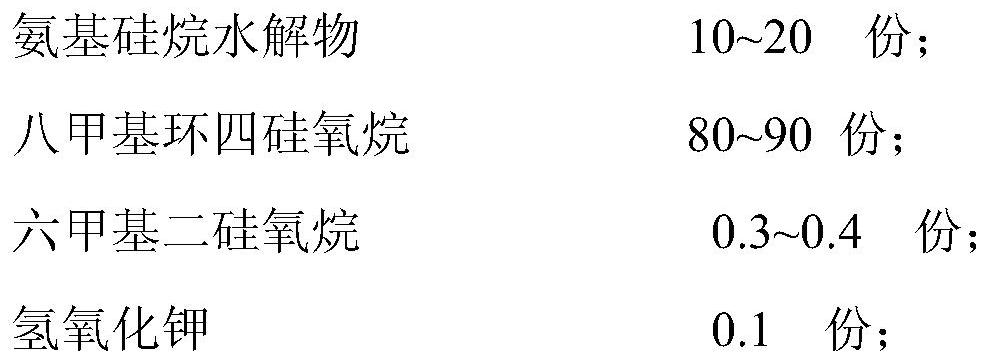

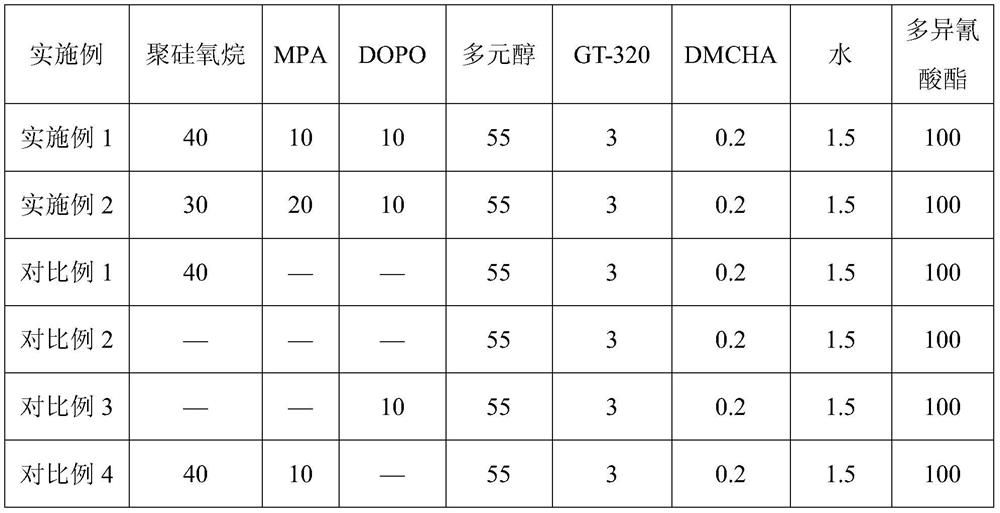

[0042] Weigh 150ml of γ-aminopropylmethyldiethoxysilane and 150ml of deionized water, stir and react at 90°C for 4.5h to obtain aminosilane hydrolyzate (HAPMS). 10 parts by weight of HAPMS, 90 parts by weight of octamethylcyclotetrasiloxane (D 4 ), 0.4 parts by weight of hexamethyldisiloxane (MM) and 0.1 parts by weight of potassium hydroxide (KOH) was heated to 140° C., stirred and reacted for 6 hours to obtain polysiloxane. 40 parts by weight of polysiloxane and 10 parts by weight of maleopimaric acid (MPA) were weighed, heated to 91° C. and stirred for 4 hours. After the reaction is completed, weigh 40 parts by weight of the above product and 10 parts by weight of DOPO, dissolve them in 300ml of chloroform, react at 50°C for 12 hours, and remove the solvent by rotary evaporation to obtain maleopimaric acid modified silicon-phosphorus synergistic flame retardant . Weigh 55 parts by weight of polyether polyol (ZS4110, Jiangsu Zhongshan Chemical Co., Ltd.), 45 parts by weigh...

Embodiment 2

[0048] Weigh 150ml of γ-aminopropylmethyldiethoxysilane and 150ml of deionized water, stir and react at 90°C for 4.5h to obtain aminosilane hydrolyzate (HAPMS). 20 parts by weight of HAPMS, 80 parts by weight of octamethylcyclotetrasiloxane (D 4 ), 0.3 parts by weight of hexamethyldisiloxane (MM) and 0.1 parts by weight of potassium hydroxide (KOH) was heated to 140° C., stirred and reacted for 6 hours to obtain polysiloxane. 30 parts by weight of polysiloxane and 20 parts by weight of maleopimaric acid (MPA) were weighed, heated to 91° C. and stirred for 4 hours. After the reaction is completed, weigh 40 parts by weight of the above product and 10 parts by weight of DOPO, dissolve them in 300ml of chloroform, react at 50°C for 12 hours, and remove the solvent by rotary evaporation to obtain maleopimaric acid modified silicon-phosphorus synergistic flame retardant . Weigh 55 parts by weight of polyether alcohol (ZS4110, Jiangsu Zhongshan Chemical Co., Ltd.), 45 parts by weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com