Colorful artistic resin

A colorful and artistic technology, applied in the field of resin and its synthesis, can solve the problems of easy detachment, single mixing of resin and pigment, etc., and achieve the effect of improving stability, reducing the risk of color fading, and good protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

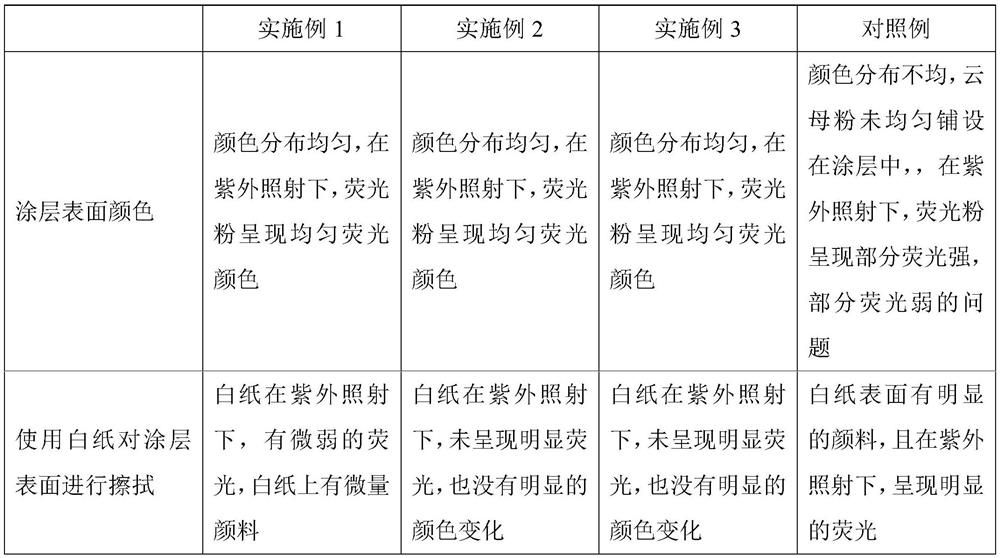

Examples

Embodiment 1

[0030] The preparation method of colorful artistic resin of the embodiment of the present invention is as follows:

[0031] Step 1: Take 50 parts by weight of hydroxyacrylate in 30 parts by weight of water, add 5 parts by weight of 1-100nm mica powder, and shake to form a uniform mixed solution;

[0032] Step 2: Take the mixed solution for coating and curing, and dry at 150°C for 4 hours to form a coating;

[0033] Step 3: crushing, grinding, and sieving the coating to obtain resin particles of 300-400 mesh;

[0034] Step 4: Soak the resin particles in 50 parts by weight of water, add 10 parts by weight of pigment and 100 parts by weight of hydroxyacrylate, shake to form a uniform mixed solution;

[0035] Step 5: Take the mixed solution for coating and curing, and dry at 150°C for 4 hours to form a coating;

[0036] Step 6: Grinding, grinding, and sieving the coating to obtain 50-100 mesh resin particles, which is the colorful art resin of the embodiment of the present inven...

Embodiment 2

[0039] The preparation method of colorful artistic resin of the embodiment of the present invention is as follows:

[0040] Step 1: Take 25 parts by weight of hydroxyacrylate and 25 parts by weight of aminoacrylate in 30 parts by weight of water, add 5 parts by weight of 1-100nm mica powder, and shake to form a uniform mixed solution;

[0041] Step 2: Take the mixed solution for coating and curing, and dry at 150°C for 4 hours to form a coating;

[0042] Step 3: crushing, grinding, and sieving the coating to obtain resin particles of 300-400 mesh;

[0043] Step 4: Soak the resin particles in 50 parts by weight of water, add 10 parts by weight of pigments and 100 parts by weight of hydroxy acrylate, vibrate and mix well;

[0044] Step 5: Take the mixed solution for coating and curing, and dry at 150°C for 4 hours to form a coating;

[0045] Step 6: Grinding, grinding, and sieving the coating to obtain 50-100 mesh resin particles, which is the colorful art resin of the embodim...

Embodiment 3

[0048] The preparation method of colorful artistic resin of the embodiment of the present invention is as follows:

[0049] Step 1: Take 50 parts by weight of hydroxyacrylate in 30 parts by weight of water, add 5 parts by weight of 1-100nm mica powder, and shake to form a uniform mixed solution;

[0050] Step 2: Take the mixed solution for coating and curing, and dry at 150°C for 4 hours to form a coating;

[0051] Step 3: crushing, grinding, and sieving the coating to obtain resin particles of 300-400 mesh;

[0052] Step 4: Soak the resin particles in 50 parts by weight of acetone, soak at 40°C for 1 hour, add 10 parts by weight of pigment and shake, add 20 parts by weight of isophorone diisocyanate, shake at 60°C for 2 hours After forming a uniform mixed solution, add 80 parts by weight of hydroxy acrylate, shake and mix;

[0053] Step 5: Take the mixed solution for coating and curing, and dry at 150°C for 4 hours to form a coating;

[0054] Step 6: Grinding, grinding, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com