Economical thin-specification Q355B steel plate and preparation method thereof

A Q355B, thin-gauge technology, applied in the field of economical thin-gauge Q355B steel plate and its preparation, can solve the problems of slow rolling rhythm, achieve high rolling efficiency, improve rolling efficiency, and improve product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

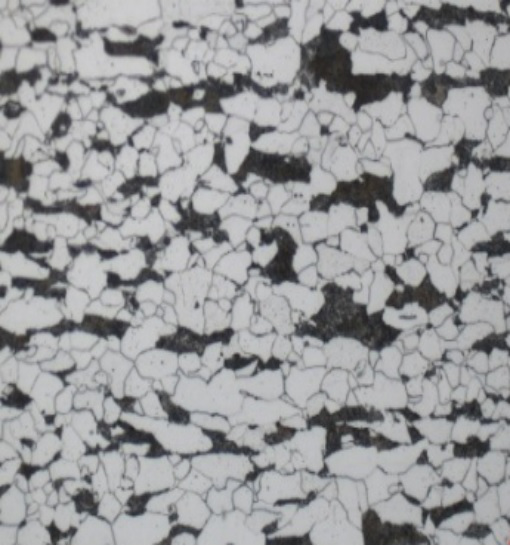

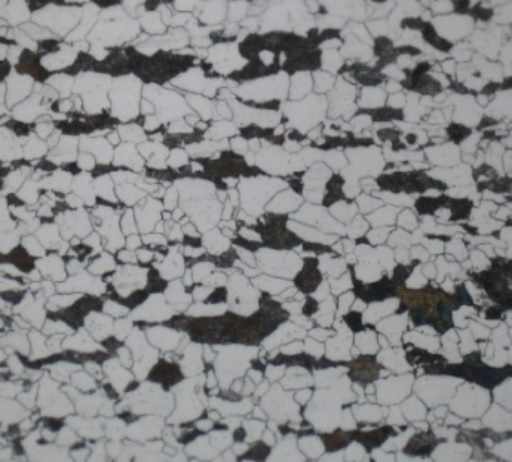

Image

Examples

Embodiment

[0031] An economical thin-gauge Q355B steel plate, the economical thin-gauge Q355B steel plate contains components and weight percentages: C 0.16-0.19%, Si≤0.24%, Mn≤0.95%, Al 0.020-0.045%, Nb 0.008 ~0.015%, Cr≤0.10%, P≤0.025%, S≤0.008%, N≤0.080%, and the rest are iron and unavoidable impurity elements.

[0032] The carbon equivalent Ceq[=C+Mn / 6+(Cr+Mo+V) / 5+(Cu+Ni) / 15] of the economical thin gauge Q355B steel plate is ≤ 0.45%.

[0033] The process route for preparing economical thin-gauge Q355B steel plate is: hot metal KR pre-desulfurization, converter smelting, LF refining, soft stirring, slab continuous casting, slab reheating, rough rolling, finish rolling, rapid cooling of steel plate, hot straightening of steel plate , Cooling on the cooling bed, shearing, storage.

[0034] After the KR pre-desulfurization treatment of the molten iron, the S content of the molten iron is ≤0.010%, and after the treatment in the LF refining furnace, the S content of the molten steel is ≤0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com