Garbage self-heating type continuous pyrolysis device

A self-heating and garbage technology, applied in lighting and heating equipment, combustion methods, combustion types, etc., can solve the problems of low utilization rate of pyrolysis gas and slow waste disposal speed, and achieve the goal of increasing speed and utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

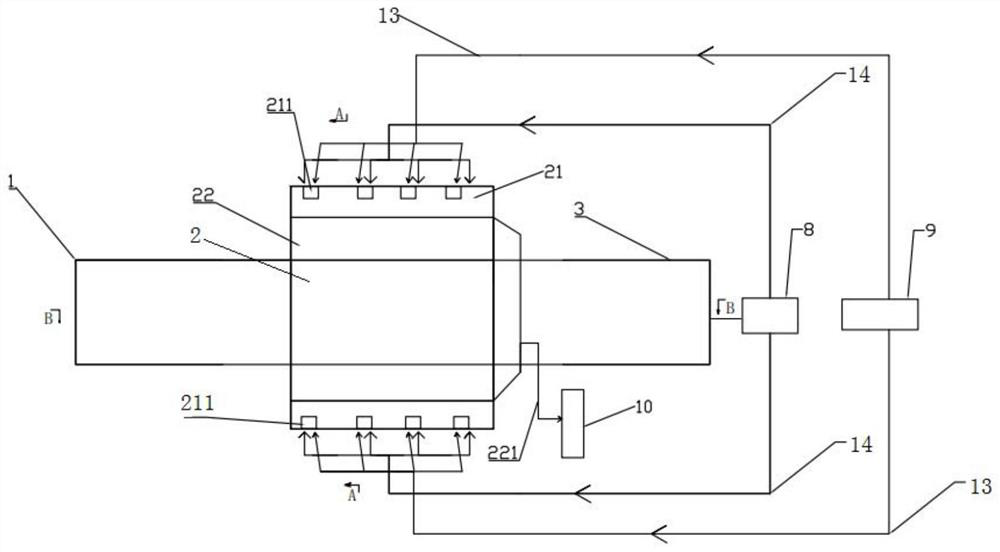

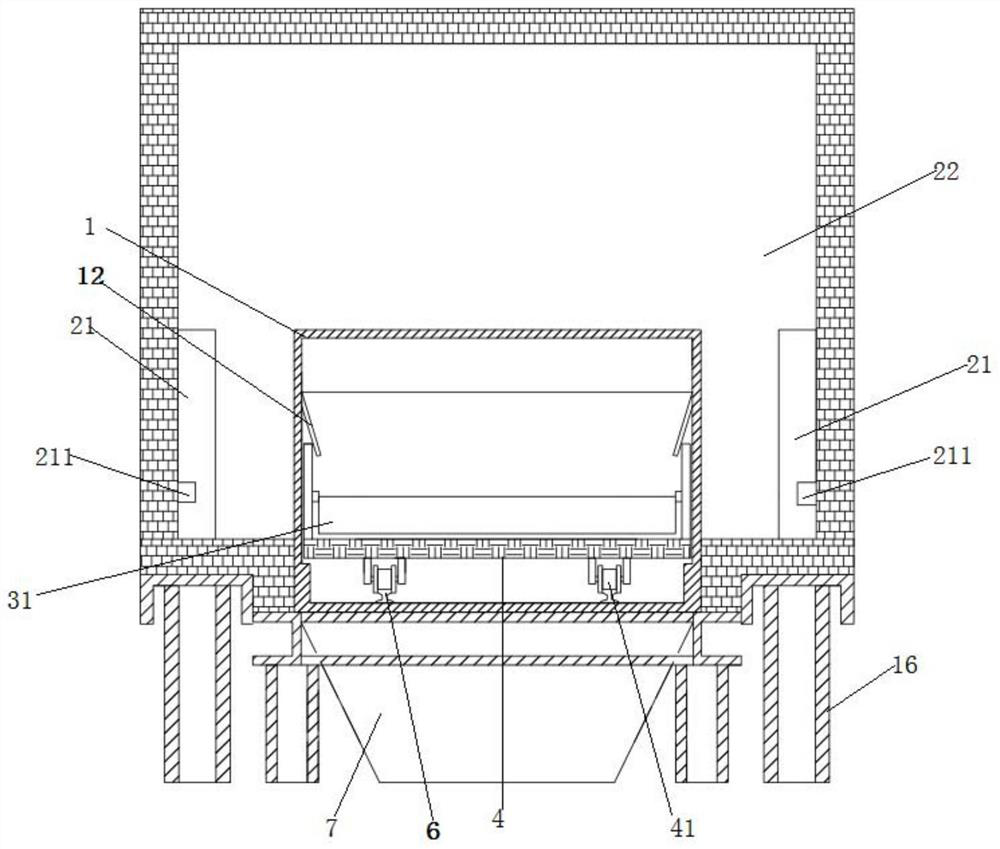

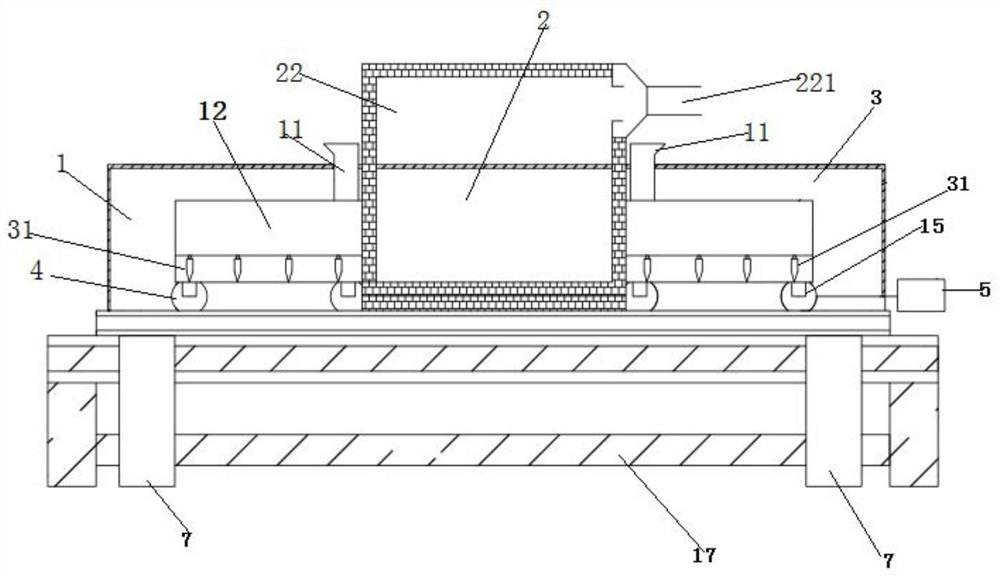

[0061] The basic structure of the garbage self-heating continuous pyrolysis device in this embodiment adopts the structure of the garbage self-heating continuous pyrolysis device in the specific embodiment.

[0062] Furthermore, the combustion chamber and the flue gas chamber are rapidly assembled furnace walls on site, which are composed of metal frames and masonry. The wall is installed on the metal bracket connected to the steel beam of the combustion furnace. The weight of the wall is transmitted to the frame of the combustion furnace through the steel member. L*W*H (length, width, height, the same below) is 6.0m*2.0m*1.5m. The size L*W*H of the pyrolysis furnace is 19.0m*1.0m*1.0m, and the size L*W*H of the pyrolysis zone is 6.0m*1.0m*1.0m. The L*W*H of the mobile garbage truck is 6.0m*0.8m*0.3m.

[0063] A water-cooled jacket can be designed around the inlet of the first material zone 1 or the second material zone 3 of the pyrolysis furnace to prevent the waste in the ...

Embodiment 2

[0065] The combustion chamber and flue gas chamber are quick-fit furnace walls on site, consisting of metal frames and masonry. The wall is installed on the metal bracket connected to the steel beam of the combustion furnace. The weight of the wall is transmitted to the frame of the combustion furnace through the steel member. The size L*W*H (length, width, height, the same below) of the flue gas chamber 22 is 4.0m*2.0m*1.5m. The size L*W*H of the pyrolysis furnace is 12.5m*1.0m*1.0m, and the size L*W*H of the pyrolysis zone is 4.0m*1.0m*1.0m. The L*W*H of the mobile garbage truck is 4.0m*0.8m*0.4m.

[0066] In the garbage self-heating continuous pyrolysis device of the present invention, the garbage trolley located in the first material area 1 is pushed to the pyrolysis area 2 under the action of the hydraulic propulsion mechanism 4. The discharge valve of the garbage hopper near the solution area 2 is opened, and the garbage gradually falls into the garbage trolley during ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com