Smoke prevention and exhaust supporting system for air film building and using method

An air-film building, smoke prevention and exhaust technology, applied in building components, ventilation systems, building rescue and other directions, can solve the problems of high technical complexity, low reliability, misunderstanding of basic principles, etc., to achieve strong operability, step-by-step clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] Below in conjunction with the examples, the present invention is further described, the following examples are illustrative, not limiting, and the protection scope of the present invention cannot be limited by the following examples.

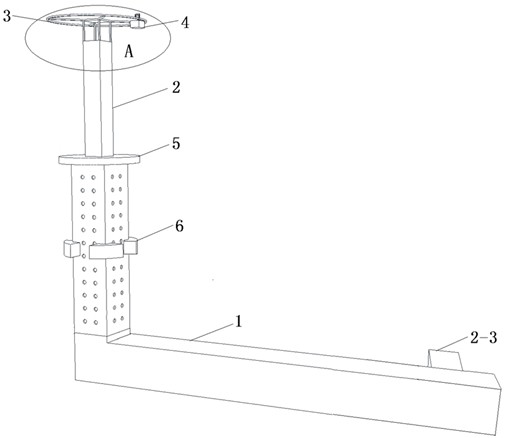

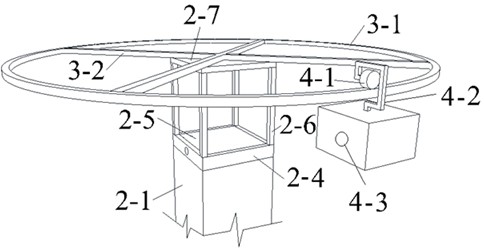

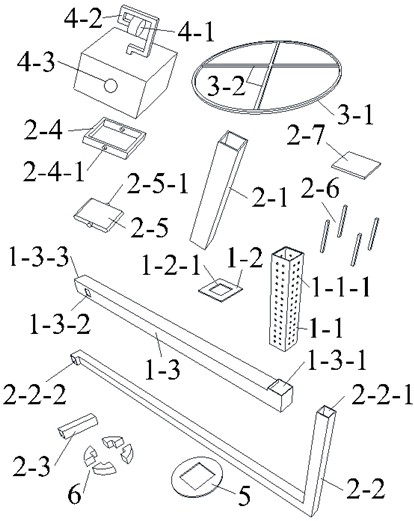

[0065] like Figure 1 to Figure 7 As shown, a smoke prevention support system for air film buildings, the smoke prevention support system consists of an external air supply pipe 1, an internal smoke exhaust pipe 2, a collapse support ring 3, a fire inspection system 4, and an emergency lighting device 5 , anti-collision unpacking 6 components;

[0066] The external air supply pipe 1 is composed of an air supply pipe 1-1, a return-shaped top cover 1-2, and an L-shaped ground pipe 1-3;

[0067] The air supply pipe 1-1 has a rectangular cross section, and several air supply holes 1-1-1 communicated with the air supply pipe inner cavity are respectively provided on the surrounding elevation of the air supply pipe 1-1, and the total height of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com