Processing technology of flexible vapor chamber and flexible vapor chamber

A processing technology and vapor chamber technology, which is applied in lighting and heating equipment, indirect heat exchangers, etc., can solve problems such as damage to the vapor chamber, damage to the internal steam channel, and unfavorable performance of the vapor chamber, so as to improve applicability, The effect of increasing applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

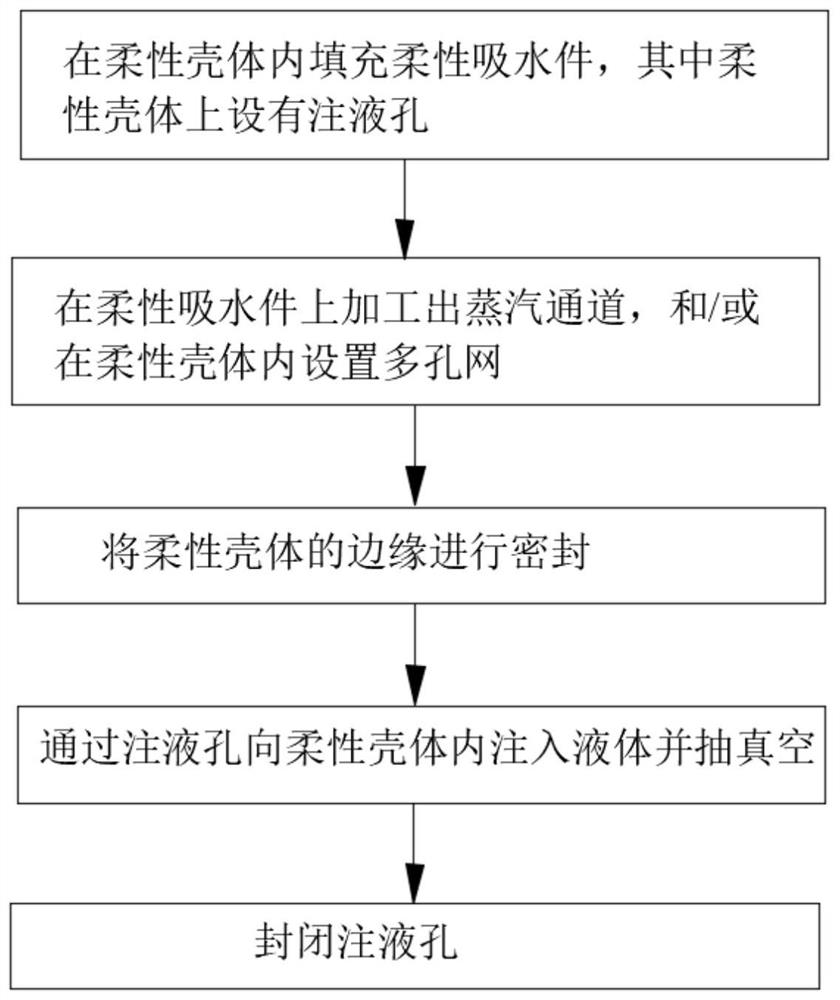

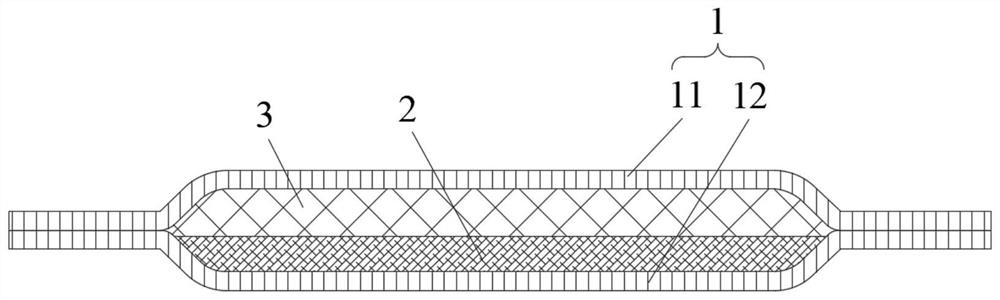

[0034] Such as figure 1 and figure 2 As shown, this embodiment provides a processing technology for a flexible vapor chamber, which includes the following steps:

[0035] filling the flexible water-absorbing part 2 in the flexible shell 1;

[0036] A porous net 3 is arranged in the flexible shell 1;

[0037] sealing the edge of the flexible housing 1;

[0038] Inject liquid into the chamber through the liquid injection hole and evacuate it;

[0039] Seal the liquid injection hole to prevent the liquid in the holding chamber from leaking.

[0040] In other embodiments, the porous net 3 may also be installed on the flexible water-absorbing element 2 first, and then the flexible water-absorbing element 2 and the porous net 3 are filled in the flexible shell 1 .

[0041] Specifically, when sealing the edge of the flexible housing 1 , one of the processing techniques of gluing, hot melting, ultrasonic welding, high frequency welding or laser welding is used. When sealing the...

Embodiment 2

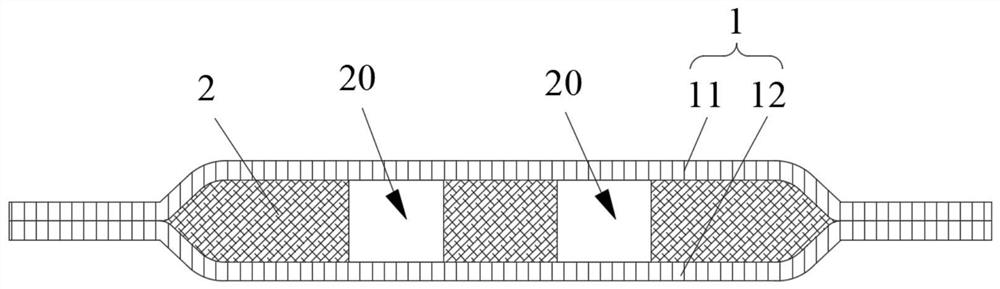

[0051] Such as image 3 As shown, this embodiment provides a processing technology of a flexible temperature chamber, and the processing technology of the flexible temperature chamber includes the following steps:

[0052] filling the flexible water-absorbing part 2 in the flexible shell 1;

[0053] A steam channel 20 is processed on the flexible water-absorbing member 2;

[0054] sealing the edge of the flexible housing 1;

[0055] Inject liquid into the chamber through the liquid injection hole and evacuate it;

[0056] Seal the liquid injection hole to prevent the liquid in the holding chamber from leaking.

[0057] In other embodiments, the steam channel 20 may also be processed in the flexible shell 1 first, and then the flexible water-absorbing member 2 is filled in the flexible shell 1 .

[0058] Such as image 3 As shown, this embodiment also provides a flexible temperature chamber, which includes a flexible housing 1 and a flexible water-absorbing member 2, the f...

Embodiment 3

[0063] Such as Figure 4 As shown, this embodiment provides a processing technology of a flexible temperature chamber, and the processing technology of the flexible temperature chamber includes the following steps:

[0064] filling the flexible water-absorbing part 2 in the flexible shell 1;

[0065] A steam channel 20 is processed on the flexible water-absorbing member 2, and the porous net 3 is filled in the steam channel 20;

[0066] sealing the edge of the flexible housing 1;

[0067] Inject liquid into the chamber through the liquid injection hole and evacuate it;

[0068] Seal the liquid injection hole to prevent the liquid in the holding chamber from leaking.

[0069] In other embodiments, the steam channel 20 can also be processed on the flexible water-absorbing part 2 first, and the porous net 3 is filled in the steam channel 20, and then the flexible water-absorbing part 2 with the filled porous net 3 is filled in the flexible shell In body 1.

[0070] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com