Conductive connecting piece for realizing electric conduction based on liquid metal

A technology of liquid metal and conductive connection, which is applied in the direction of electrical connection combined with liquid connection, parts of the connection device, and connection with permanent deformation. Contact effect, reduction of contact resistance, and effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

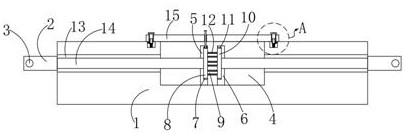

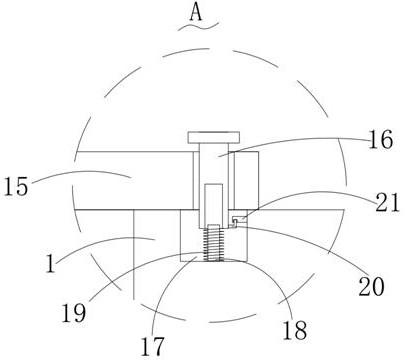

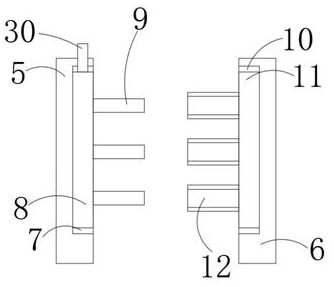

[0029] Please refer to Figure 1 to Figure 3, in the first embodiment of the present invention, the conductive connector for conducting electricity based on liquid metal includes: a first mounting block 1; two copper blocks 2, and the two copper blocks 2 are fixedly installed on the first mounting block On the outer walls of both sides of the block 1; two connecting holes 3, the two connecting holes 3 are set on the two copper blocks 2; the first fixing groove 4, the first fixing groove 4 is set on the The top of the first mounting block 1; the first fixing block 5, the first fixing block 5 is fixedly installed on the bottom inner wall of the first fixing groove 4; the second fixing block 6, the second fixing block 6 is fixed Installed on the bottom inner wall of the first fixing groove 4; the first installation groove 7, the first installation groove 7 is opened on the side outer wall of the first fixing block 5; the first copper sheet 8, the The first copper sheet 8 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com