A direct-current brush motor and cooling fan

A DC brushed motor and brush technology, which is applied to the cooling of the engine, electromechanical devices, electrical components, etc., to achieve the effect of reducing power consumption and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0026] This program proposes a cooling fan, see figure 1 , the cooling fan includes an impeller 100 and a DC brushed motor 200 that drives the impeller 100 to rotate.

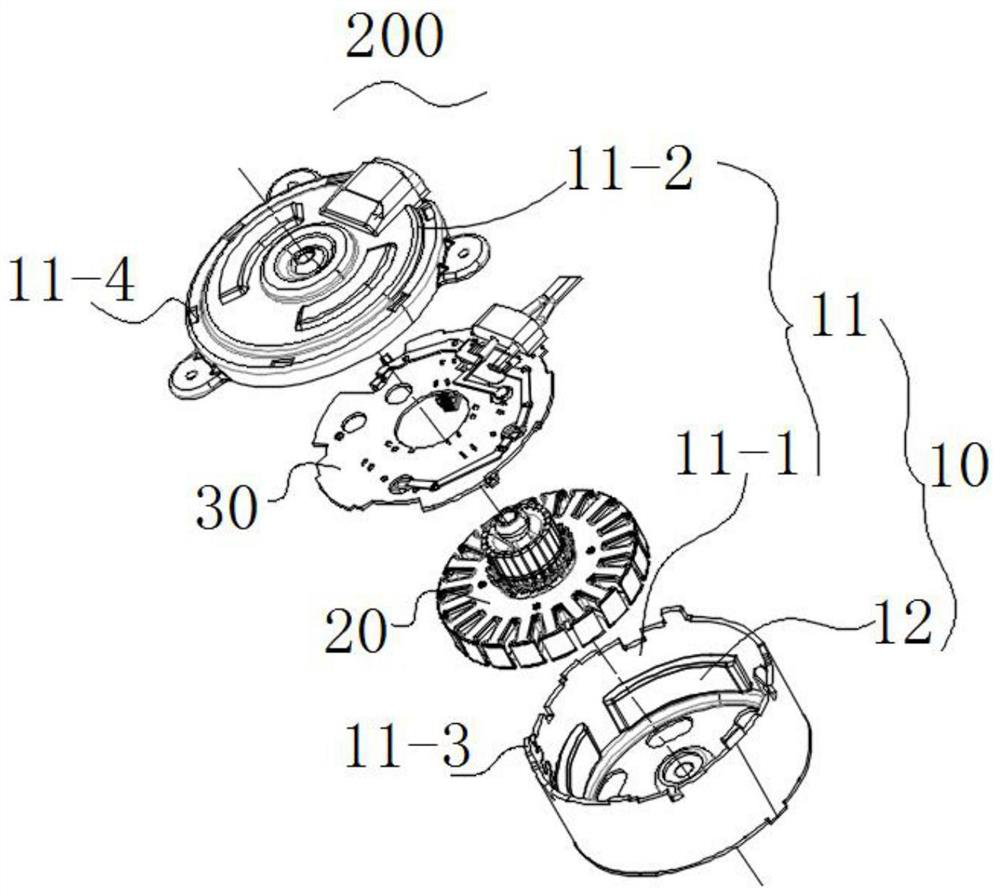

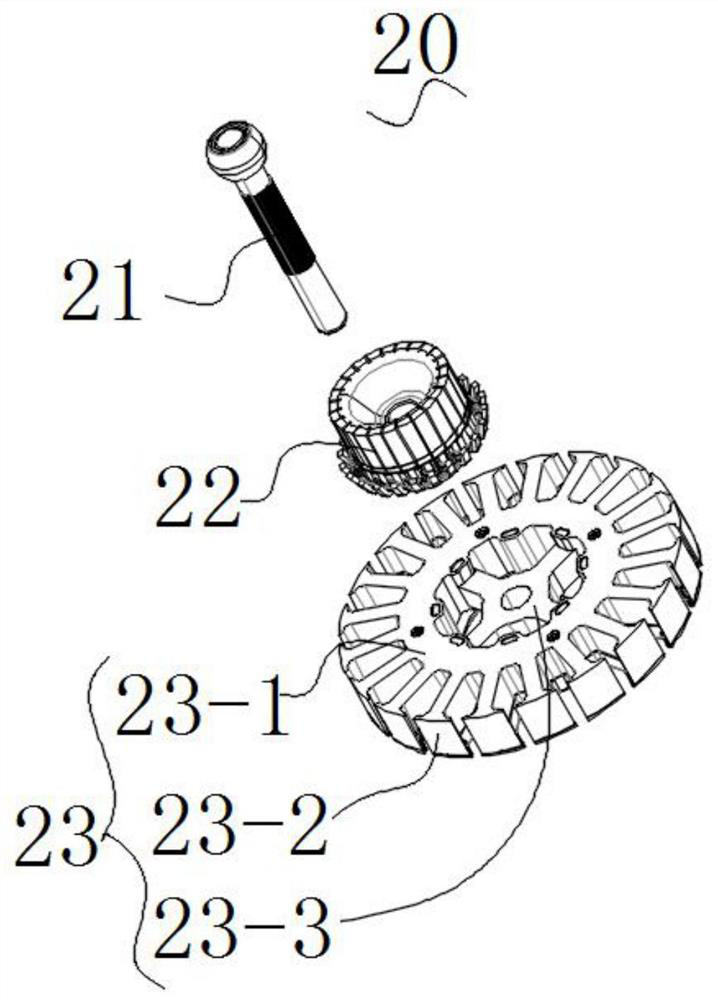

[0027] Among them, see Figure 2-Figure 5 , DC brushed motor 200 includes a stator 10 and a rotor 20 that can rotate relative to the stator 10; wherein the stator 10 includes a housing 11 and 2n pairs of magnetic poles 12 arranged inside the housing 11; the rotor 20 includes a rotating shaft 21, fixed on the rotating shaft The hook commutator 22 on 21 and the magnetizer 23, the winding group (not shown) that is wound in the magnetizer 23 and is electrically connected with the hook of the hook commutator 22 in sequence, and the winding groups communi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com