Supercritical water oxidation reactor and working method thereof

A technology of supercritical water oxidation and supercritical water, applied in chemical instruments and methods, chemical/physical/physicochemical fixed reactors, control/regulation processes, etc. Problems such as clogging, to achieve the effect of easy operation of the treatment process, simple treatment process, and solution to the difficulty of degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

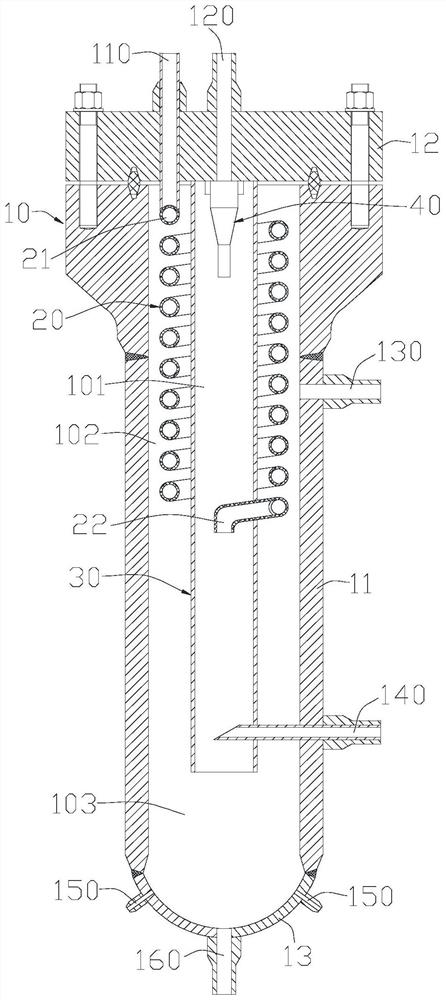

[0030] like figure 1 As shown, the supercritical water oxidation reactor according to an embodiment of the present invention includes a closed reaction vessel 10 and a spiral coil 20 arranged in the reaction vessel 10 .

[0031] Wherein, the reaction vessel 10 is provided with a central reaction channel 101 , an annular chamber 102 and a communication chamber 103 . The annular chamber 102 is located at the periphery of the central reaction channel 101, and the communication chamber 103 is located at the inner bottom of the reaction vessel 10, also below the central reaction channel 101; the central reaction channel 101 communicates with the annular chamber 102 through the communication chamber 103.

[0032] The top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com