A kind of single-phase multi-component rare earth magnesium alloy biodegradable material and preparation method thereof

A biodegradable material, rare earth magnesium technology, applied in the field of biomedical alloy materials, can solve the problems of compound and alloy element toxicity, etc., achieve good biological safety, improve performance, improve corrosion resistance and uniformity of corrosion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

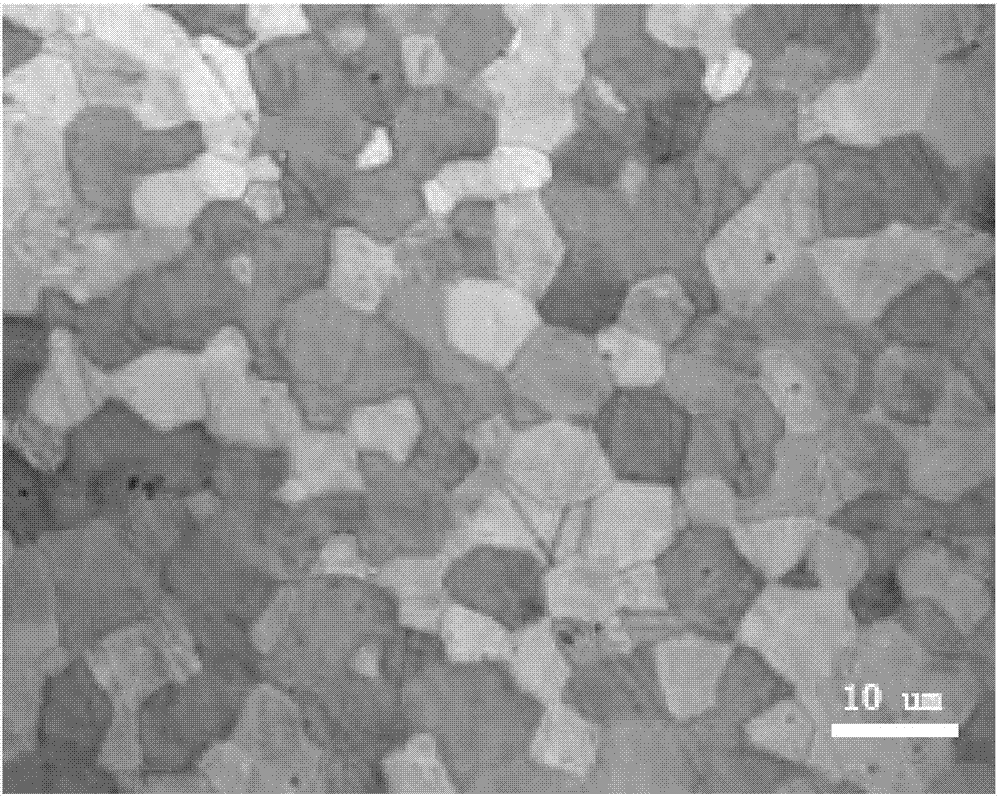

Image

Examples

Embodiment 1

[0034]The raw materials are configured according to the following alloy composition ratio: Gd 5%, Dy 3%, Y 1%, Zn 1.0%, Zr 0.4%, the rest is Mg, the total amount of impurity elements is ≤0.005%, and Fe in impurity elements is ≤0.0005% , Ni≤0.0005%, Cu≤0.001%, the raw materials are 99.99% Mg, 99.99% Zn, Mg25Gd, Mg25Dy, Mg25Y, Mg30Zr, and the raw materials are cleaned with weak acid and alkali and baked for later use. The preparation of the alloy is smelted with a low-carbon steel crucible that does not contain Ni and is coated with BN coating on the inner wall of the crucible. When the crucible is heated to 650 ° C, pure Mg is added for melting, and Ar+0.2% SF is used. 6 Melting under protection; when the pure Mg is completely melted and the temperature rises to 680°C, use a graphite bell jar to press other raw materials into the Mg melt, then heat up to 730°C, use rotary jetting for stirring and purification treatment, and rotary jetting of gas It is high-purity Ar gas, the ga...

Embodiment 2

[0040] The raw materials are configured according to the following alloy composition ratio: Gd 2%, Dy 6%, Y 1%, Zn 0.5%, Zr 0.6%, the rest is Mg, the total amount of impurity elements is ≤0.005%, and Fe in impurity elements is ≤0.0005% , Ni≤0.0005%, Cu≤0.001%, the raw materials are 99.99% Mg, 99.99% Zn, Mg25Gd, Mg25Dy, Mg25Y, Mg30Zr, and the raw materials are cleaned with weak acid and alkali and baked for later use; the preparation of the alloy is made of Ni-free and The inner wall of the crucible is smelted with low-carbon steel crucible coated with BN paint. When the crucible is heated to 650°C, pure Mg is added for melting, and Ar+0.2% SF is used. 6 Melting under protection; when the pure Mg is completely melted and the temperature rises to 700°C, use a graphite bell jar to press alloy elements into the Mg melt, then heat up to 780°C, use rotary jetting for stirring and purification treatment, and rotary jetting of gas It is high-purity Ar gas, the gas flow rate is 30mL / mi...

Embodiment 3

[0046] The raw materials are configured according to the following alloy composition ratio: Gd 2%, Dy 3%, Y 2%, Zn 1.0%, Zr 0.6%, the rest is Mg, the total amount of impurity elements is ≤0.005%, and Fe in impurity elements is ≤0.0005% , Ni≤0.0005%, Cu≤0.001%, the raw materials are 99.99% Mg, 99.99% Zn, Mg25Gd, Mg25Dy, Mg25Y, Mg30Zr, and the raw materials are cleaned with weak acid and alkali and dried for later use. The preparation of the alloy is smelted with a low-carbon steel crucible that does not contain Ni and is coated with BN coating on the inner wall of the crucible. When the crucible is heated to 650 ° C, pure Mg is added for melting, and Ar+0.2% SF is used. 6 Melting under protection; when the pure Mg is completely melted and the temperature rises to 690°C, use a graphite bell jar to press the alloy elements into the Mg melt, then heat up to 750°C, use rotary jetting for stirring and purification, and rotary jetting of gas It is high-purity Ar gas, the gas flow rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com