Construction waste treatment device

A processing device and construction waste technology, applied in grain processing, dust removal, chemical instruments and methods, etc., can solve the problems of reducing construction waste processing costs, achieve good air cleaning ability, improve processing capacity and efficiency, and ensure safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

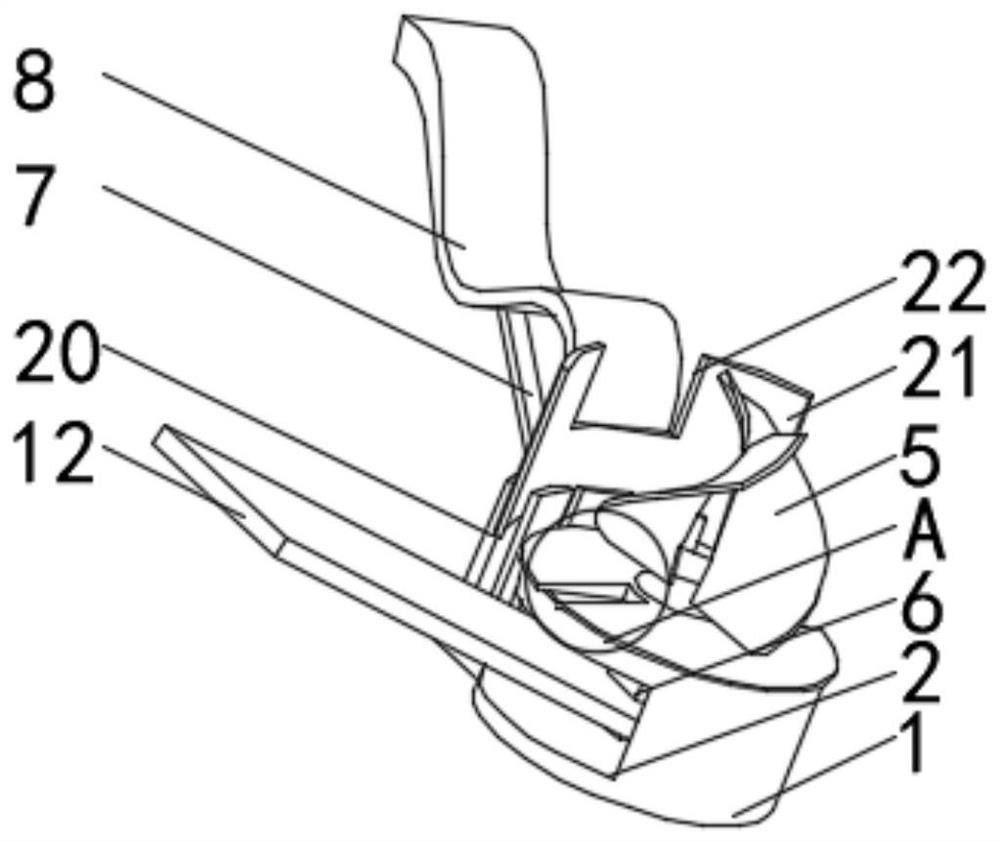

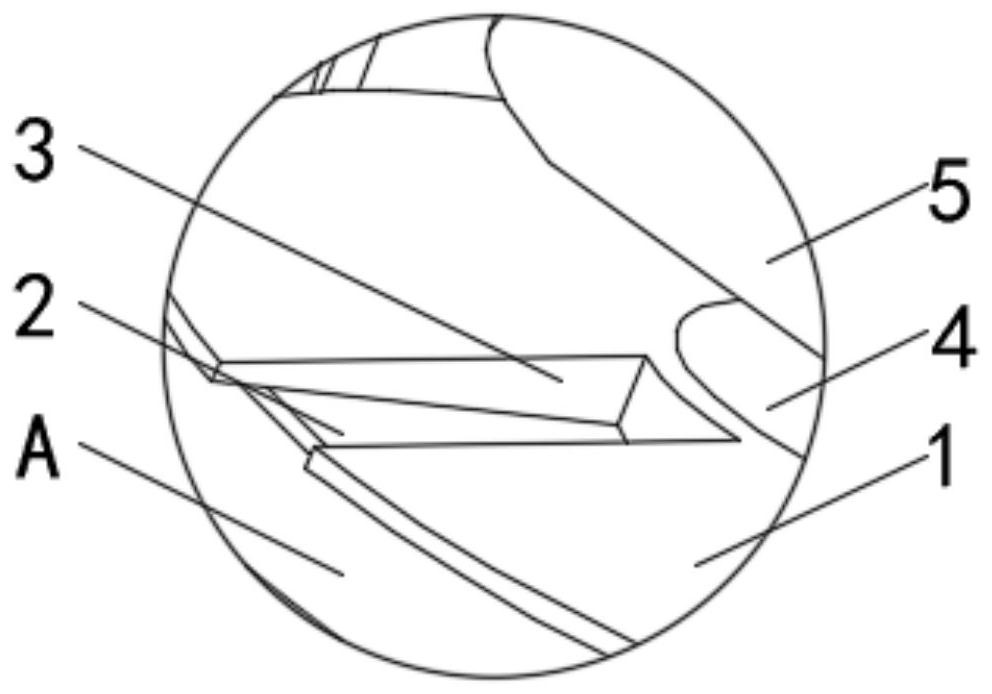

[0036] see Figure 1-2 , the present invention provides a technical solution: a construction waste treatment device, including a processing table 1, a discharge port 2 is opened on one side of the processing table 1, the top of the processing table 1 is a circular platform structure, and the top of the processing table 1 is symmetrically opened There is a discharge port 3, and the middle position of the top of the processing table 1 is rotatably connected with a rotating plate 4, and the top of the rotating plate 4 is symmetrically installed with a crushing knife 5, and the crushing knife 5 spirally rises, and one side of the processing table 1 is fixedly connected by a support rod 7 Conveying plate 8 is arranged, and conveying plate 8 is corrugated plate, and spacer 20 is evenly installed on one side of processing table 1, and spacer 21 is installed between the two sides of spacer 20, and support bar 7 is fixedly connected with spacer 20.

[0037] A feeding trough 22 is provi...

Embodiment 2

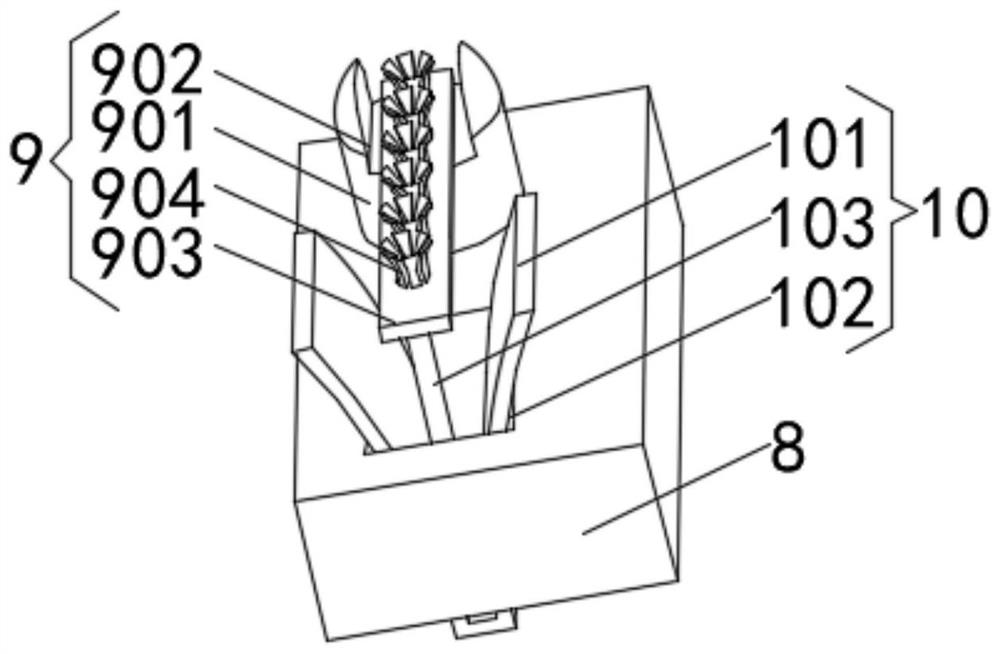

[0042] see Figure 1-3 , the present invention provides a technical solution: on the basis of Embodiment 1, a cleaning device 9 is installed on the top recessed area of the conveying plate 8, and the bottom of the cleaning device 9 is connected to the conveying plate 8 through an anti-collision device 10, and the cleaning device 9 includes Mounting block 901, the mounting block 901 is evenly installed on the top of the conveying plate 8, the top of the mounting block 901 is provided with a mounting groove 902, and a bottom plate 903 is connected between the two sides of the inner wall of the mounting groove 902, and the top of the bottom plate 903 is uniformly equipped with a cleaning Article 904.

[0043] The anti-collision device 10 includes a symmetrically installed elastic plate 101. The top of the conveying plate 8 is provided with an anti-collision hole 102 near the mounting block 901. The bottom end of the elastic plate 101 passes through the anti-collision hole 102 a...

Embodiment 3

[0047] see Figure 1-4 , the present invention provides a technical solution: on the basis of the second embodiment, one side of the elastic plate 101 is uniformly provided with a filter hole 13, and the side of the filter hole 13 away from the push rod 103 is provided with a dust collection air bag 14, and the elastic plate One side of 101 is fixedly connected with an inclined plate 15 above the filter hole 13 .

[0048] When in use, the elastic plate 101 is squeezed by the construction waste and when it descends and rises, the inclined plate 15 moves up and down at the same time. During the upward and downward movement of the inclined plate 15, the air is driven to flow, and the air with construction waste dust around the conveying plate 8 is transported by the inclined plate 15. Drive the flow through the filter hole 13 and enter the inside of the dust collection airbag 14. After the dust particles fall into the inside of the dust collection airbag 14, the air flows to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com