Iron sheet surface polishing device

A surface polishing and iron sheet technology, applied in surface polishing machine tools, grinding drives, grinding/polishing equipment, etc., can solve the problems of reducing iron sheet processing efficiency and single polishing ability, avoiding offset and improving processing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

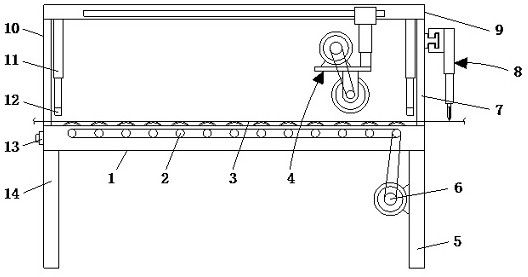

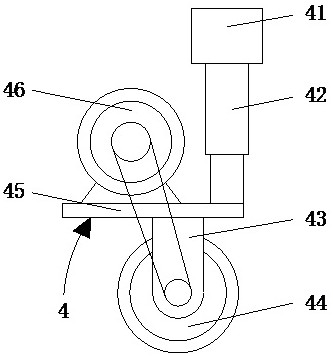

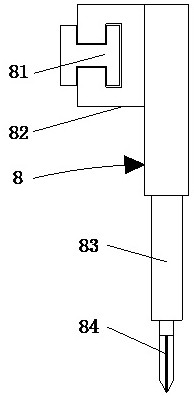

[0021] see Figure 1-5 , a kind of iron sheet surface polishing device, comprises bearing 1 and conveying motor 6, and the left and right ends of bearing 1 bottom are respectively fixedly connected with the second supporting plate 14 and the first supporting plate 5, and the second supporting plate 14 and the first supporting plate The bottom of the plate 5 is fixedly connected with a fixing mechanism, the fixing mechanism includes mounting plates installed on the front and rear ends of the second support plate 14 and the bottom of the first support plate 5, and through holes are provided around the inner surface of each mounting plate, and people pass through the mounting plates tightly. Fix the mounting plate to the reserved screw hole on the ground or the reserved screw hole of other fixing parts with the fixed screw, so as to realize the fixing requirement of the support 1, and the middle end on the left side of the first support plate 5 is fixedly installed with the convey...

Embodiment 2

[0023] see Figure 1-5, a kind of iron sheet surface polishing device, comprises bearing 1 and conveying motor 6, and the left and right ends of bearing 1 bottom are respectively fixedly connected with the second supporting plate 14 and the first supporting plate 5, and the second supporting plate 14 and the first supporting plate The bottom of plate 5 is all fixedly connected with moving mechanism, and moving mechanism is the support that road wheel is installed, and it is installed on the front and rear ends of second support plate 14 and the bottom of first support plate 5, and its moving mode is: people push with hand Support 1, so that the road wheels move, and finally drive the support 1 to move, and the middle end on the left side of the first support plate 5 is fixedly installed with the conveying motor 6, and the middle end on the left side of the support 1 is fixedly connected to the controller 13. The model of the controller 13 is DATA-7311. The two terminals of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com