Hoisting fixture for automobile flywheel casing casting and using method of the hoisting fixture

A technology of flywheel housing and fixture, which is applied in the direction of hoisting device, transportation and packaging, load hanging components, etc. It can solve the problems of poor adjustment accuracy of position change angle and high difficulty of hoisting, and achieve the effect of improving braking capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

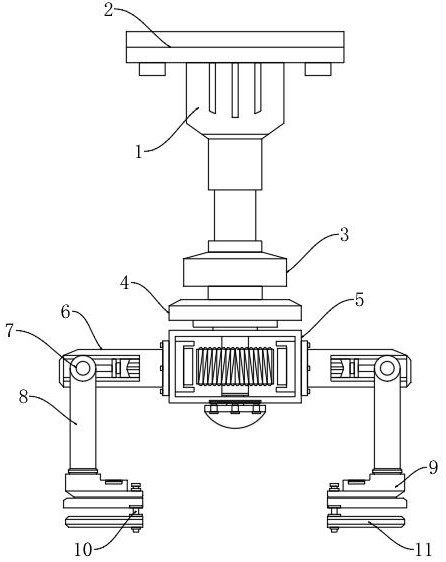

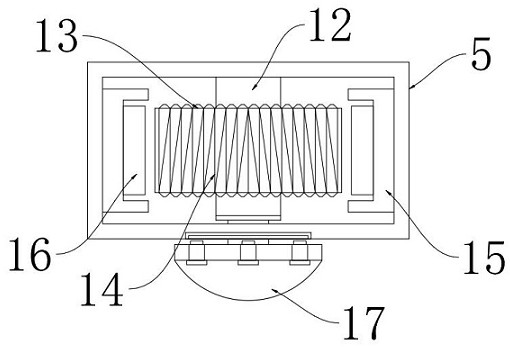

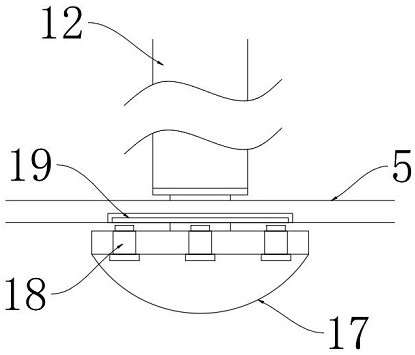

[0028] see Figure 1-6, an embodiment provided by the present invention: a hoisting jig for casting an automobile flywheel housing, comprising a telescopic hydraulic motor 1, the upper end of the telescopic hydraulic motor 1 is provided with a hoisting jig fixing plate 2, and the hoisting jig fixing plate 2 is connected to the telescopic hydraulic motor 1 screw connection, the output end of the telescopic hydraulic motor 1 is provided with a lifting jig fixed block 3, and the hoisting jig fixed block 3 is welded to the telescopic hydraulic motor 1, and the lower end of the hoisting jig fixed block 3 is provided with a bearing 4, and the bearing 4 is connected to the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com