Method for preparing mine filler by cementing solid wastes in iron and steel industry with heavy metal tailings

A solid waste and mine filling technology, applied in the direction of solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problems of environmental pollution, occupation of land resources, low comprehensive utilization rate, etc., to reduce production costs, raw materials The effect of rich sources and improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

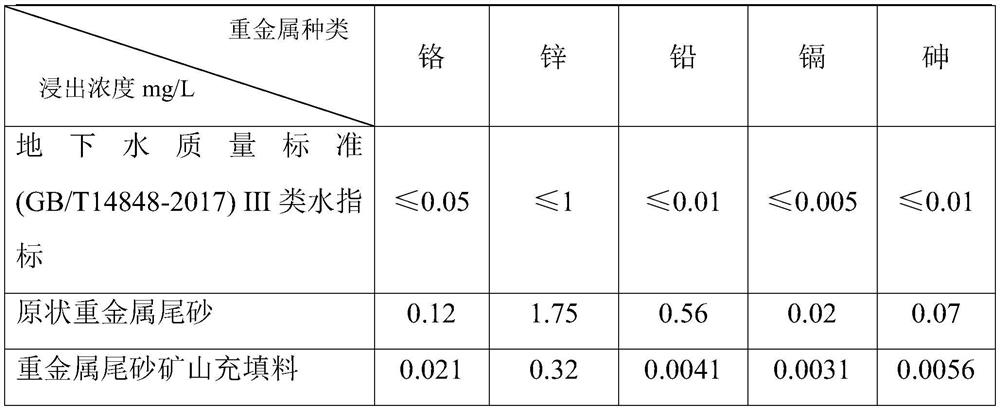

Embodiment 1

[0032] The preparation method of mine filling by cementing heavy metal tailings with industrial solid waste in the iron and steel industry: According to the weight ratio, the heavy metal tailings cementing agent formula is composed of 50% slag powder, 35% steel slag powder, 15% desulfurization ash, and externally mixed with alkali activator 4 %, activator 3%, mechanical stirring and mixing. The heavy metal tailings are first stirred and mixed evenly with the dispersant, binder and heavy metal curing agent in the mixing chamber, wherein the amount of the dispersant accounts for 0.6% of the weight of the cementitious material, and the amount of the binder is 0.25% (accounting for the dry weight of the heavy metal tailings). ), heavy metal curing agent dosage 0.5% (accounting for heavy metal tailings dry weight); Evenly, test the fluidity of the slurry with a fluidity testing instrument, put the remaining slurry into a 70.7mm*70.7mm*70.7mm test mold, put it in a standard cement c...

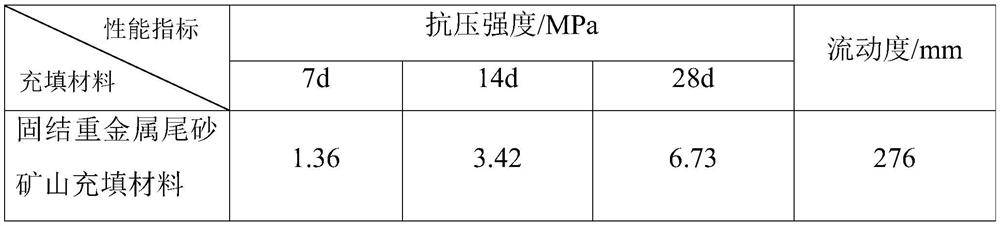

Embodiment 2

[0039] The preparation method of mine filling by cementing heavy metal tailings with industrial solid waste in the iron and steel industry: According to the weight ratio, the heavy metal tailings cementing agent formula is composed of slag powder 43%, steel slag powder 40%, desulfurization ash 17%, and alkali activator 3 %, activator 5%, mechanical stirring and mixing. The heavy metal tailings are first stirred and mixed evenly with the dispersant, binder and heavy metal curing agent in the mixing chamber, and then the cementing agent is added to the tailings mixing chamber, where the dispersant content accounts for 1.0% of the weight of the cementitious material The dosage of binder is 0.5% (accounting for the dry weight of heavy metal tailings), and the dosage of heavy metal curing agent is 0.9% (accounting for the dry weight of heavy metal tailings); the weight of cementing agent in the mine filling material is cementing agent: heavy metal tailings=1:6 , Stir the cement and...

Embodiment 3

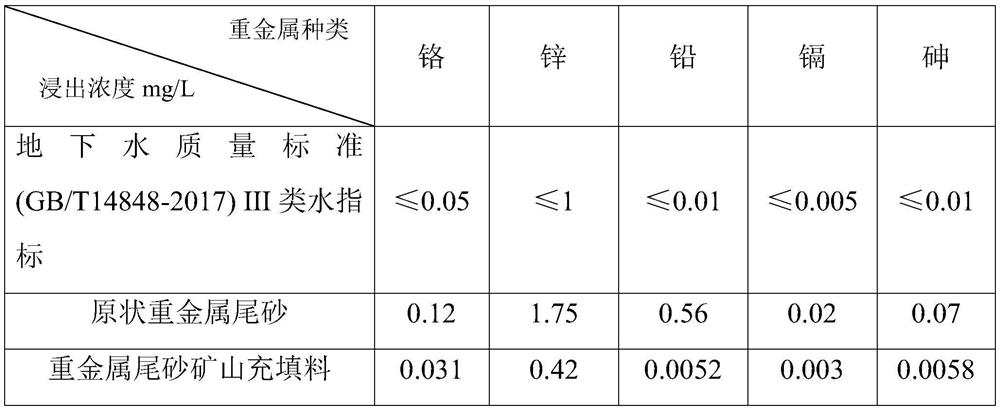

[0046] The preparation method of mine filling by cementing heavy metal tailings with industrial solid waste in the iron and steel industry: According to the weight ratio, the heavy metal tailings cementing agent formula is composed of slag powder 40%, steel slag powder 25%, desulfurization ash 35%, and alkali stimulator 5% %, activator 2%, mechanical stirring and mixing. The heavy metal tailings are mixed evenly with the dispersant, binder and heavy metal curing agent in the mixing chamber, and then the cementing agent is added to the tailings mixing chamber. The dosage of binder is 1.0% (accounting for the dry weight of heavy metal tailings), and the dosage of heavy metal curing agent is 1.2% (accounting for the dry weight of heavy metal tailings); the weight of cementing agent in the mine filling material is cementing agent: heavy metal tailings=1:5 , Stir the cement and heavy metal tailings evenly in the mixing chamber, test the fluidity of the slurry with a fluidity testin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com