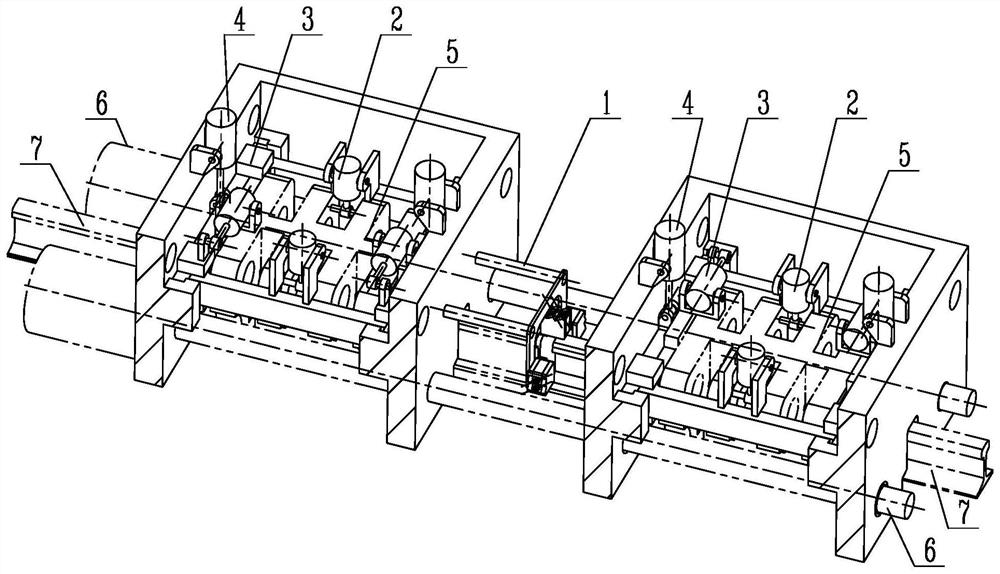

Steel rail aligning mechanism and aligning method

A technology of rails and adjustment mechanisms, which is applied in the direction of track, track laying, track maintenance, etc. It can solve the problems of limited use functions and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Embodiment 1.2: a rail alignment mechanism, the same as embodiment 1.1, the difference is that the twist adjustment oil cylinder 203, the horizontal adjustment oil cylinder 302, and the vertical adjustment oil cylinder 402 are replaced by power outputs such as geared motors, stepper motors, or leading screws device instead.

Embodiment 13

[0058] Embodiment 1.3: a kind of rail alignment mechanism, with embodiment 1.1, difference is: the guide groove of lateral guide chute 303, vertical guide chute 403, clamp rail mechanism 5 replaces with line rail or optical axis.

[0059] The above-mentioned rail alignment mechanism can automatically adjust the postures of the two rails to be welded to meet the selected rail alignment standard. It is used in rail welding equipment to realize the automatic alignment function of rails, thereby improving the efficiency and quality of rail welding, and the adaptability of existing welding machines. Reduce the workload of rail grinding in the later stage.

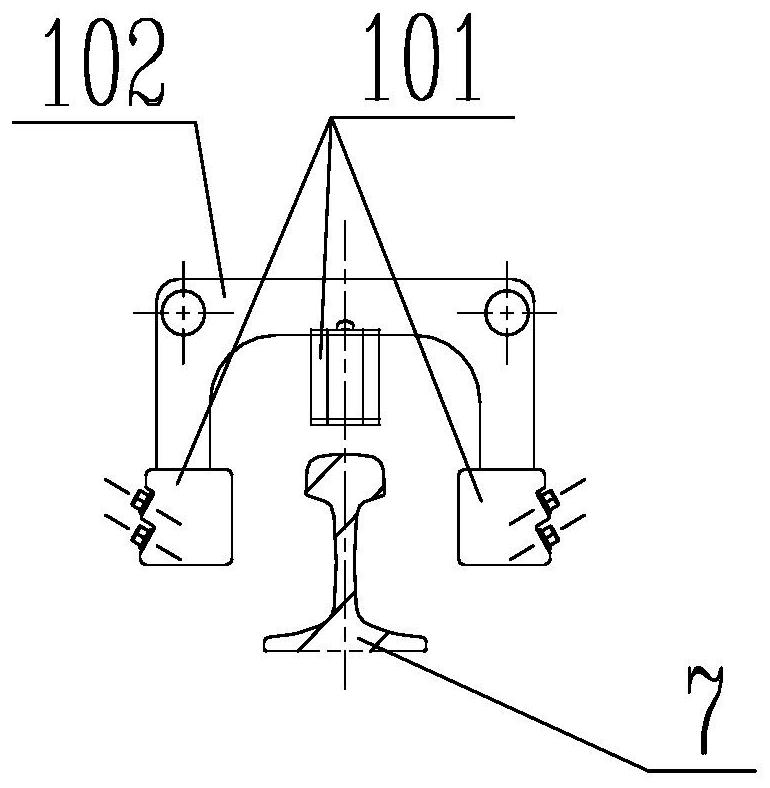

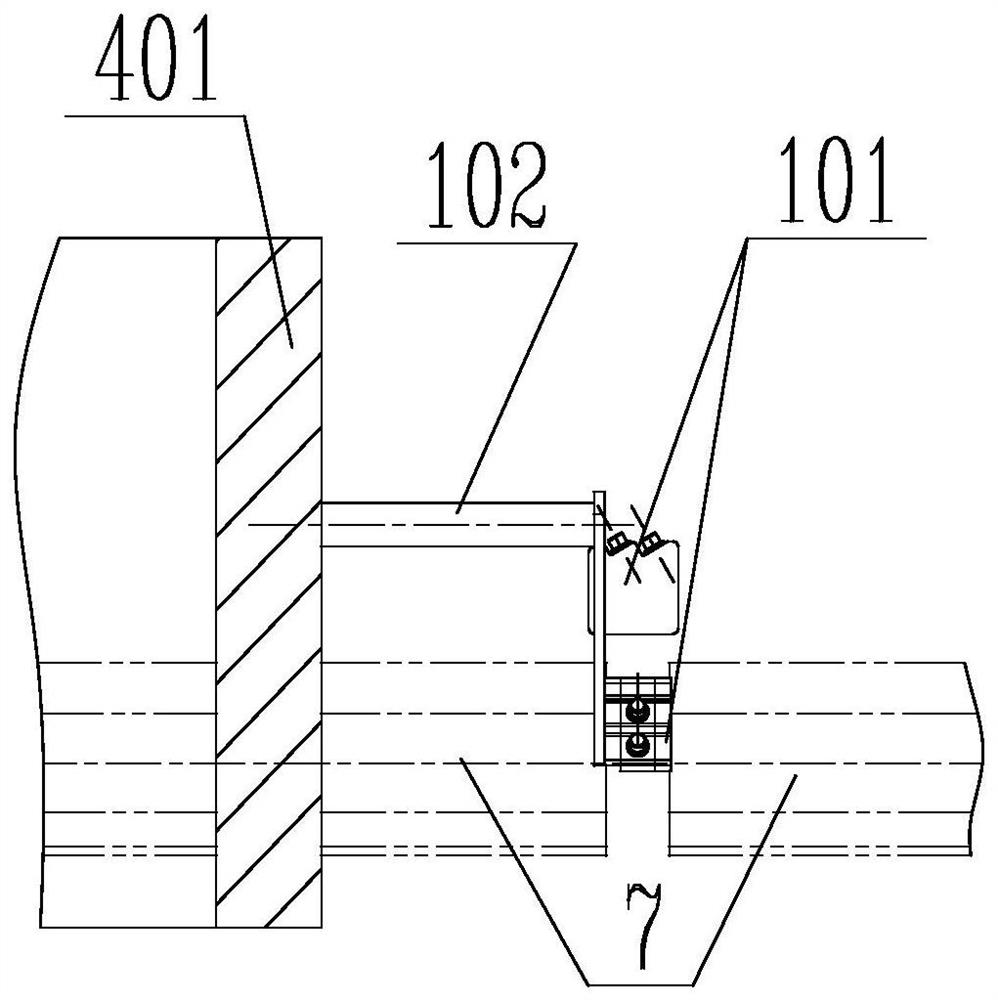

Embodiment 2

[0060] Embodiment 2.1: a rail-to-rail method, which includes placing the laser profile scanning sensor (101) on the top surface of the rail and the two sides of the rail respectively. The scanning sensor moving device (102) is fixed on the outer box (402); the scanning sensor moving device (102) drives the laser scanning sensor (101) to move in parallel to the direction of the rail (7) to scan and collect the position and profile data of the two rails. At the same time, it can stop at the joint of the two rails and monitor the alignment results of the rails in real time. The laser profile scanning sensor (101) feeds back the results to the rail attitude adjustment mechanism. The rail attitude adjustment mechanism compares the adjustment rules to obtain the required adjustment amount, and adjusts vertically or horizontally, or twists horizontally until the alignment of the rails meets the requirements. Require.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com