A method for integrally closing cantilever beams of a jack-up drilling platform

A drilling platform and cantilever beam technology, which is applied in the field of cantilever beam closing technology, can solve the problems of pile insertion failure, difficult adjustment of relative position, overall closing failure, etc., and achieve the effect of high closing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

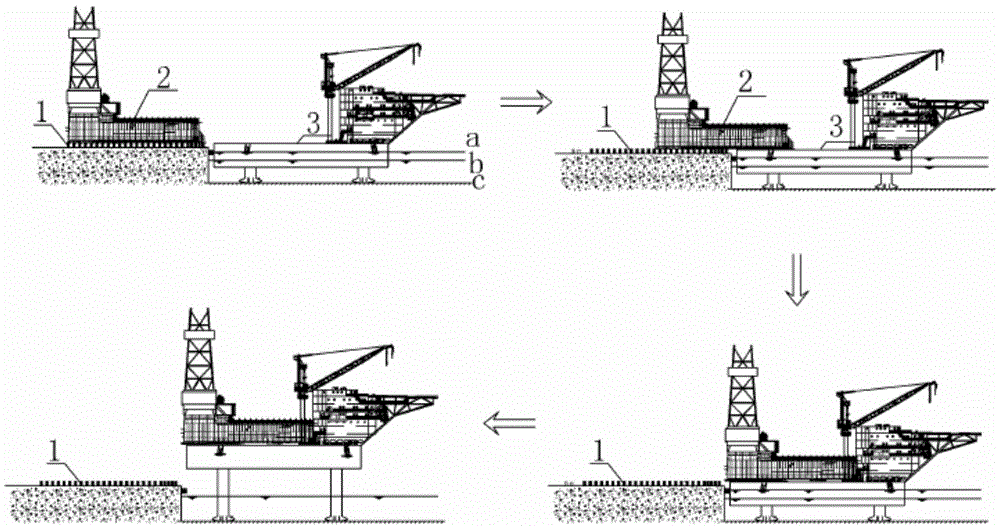

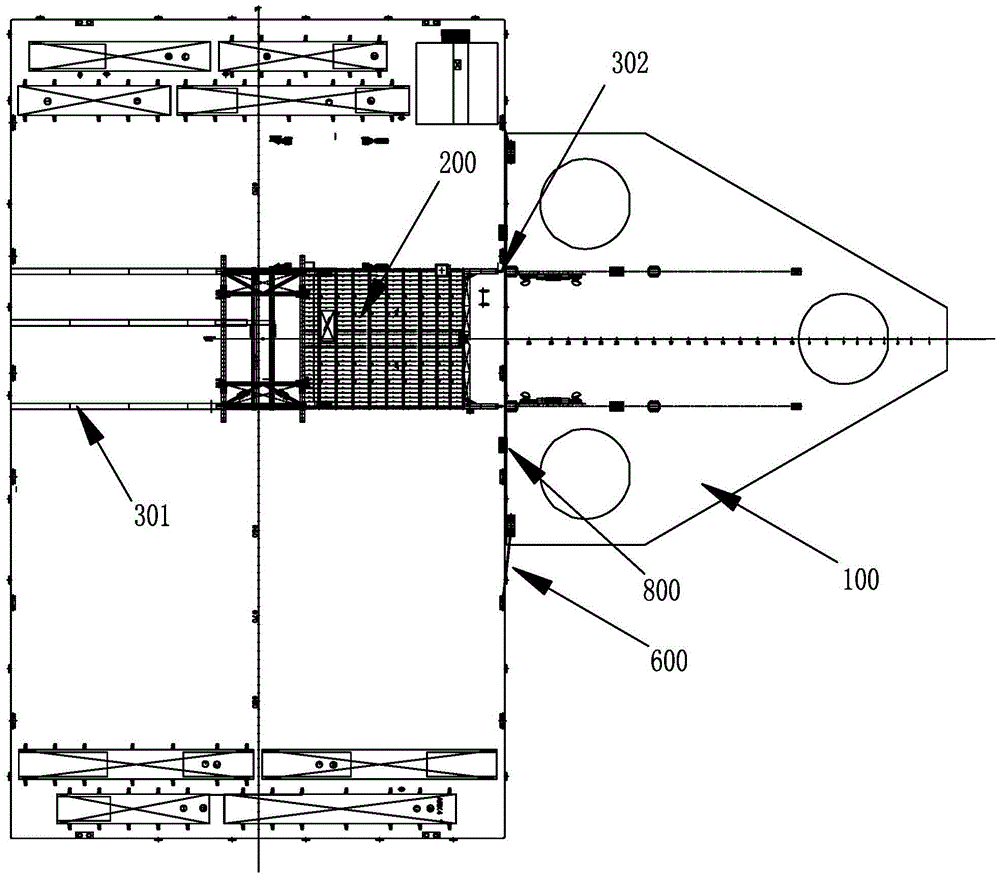

[0074] see image 3 , Figure 4 , the present invention discloses a method for closing the cantilever beam of a jack-up drilling platform as a whole, which is used for closing the cantilever beam 200 and the main hull 100 .

[0075] Such as image 3 As shown, the predetermined position of the deck 110 of the main hull 100 is provided with a fulcrum 111 for supporting the cantilever beam 200 and a grab point 112 for fixing the end of the cantilever beam 200. The main hull 100 The main hull ballast system is configured on the top, and the overall closing method of the cantilever beam of the jack-up drilling platform includes:

[0076] Step A, providing a barge 300, the barge 300 is equipped with a barge ballast system, and initially aligns and positions the barge 300 and the main hull 100;

[0077] Step B, launching the cant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com