Drilling equipment for geothermal exploration

A drilling equipment and geothermal technology, applied in drilling equipment, drilling equipment and methods, mechanical equipment and other directions, can solve the problems of poor cooling effect, scrapped drill bits, affecting the working quality of drill bits, etc., to improve the cooling and cooling effect, improve the use of Longevity, the effect of improving stability and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

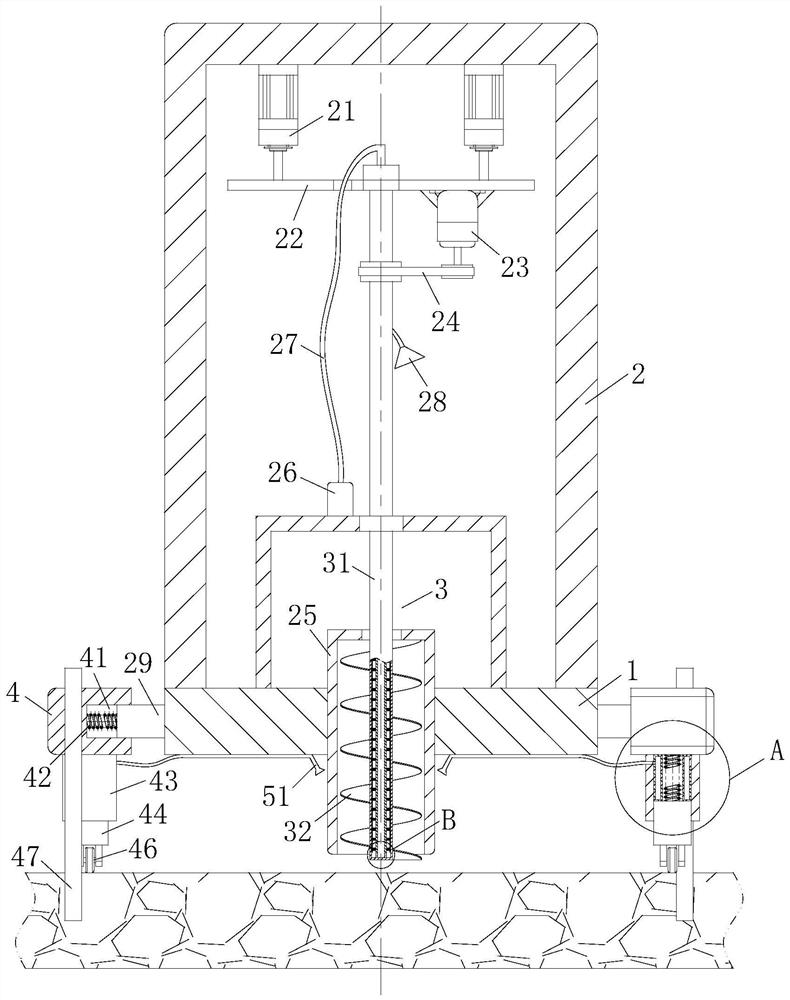

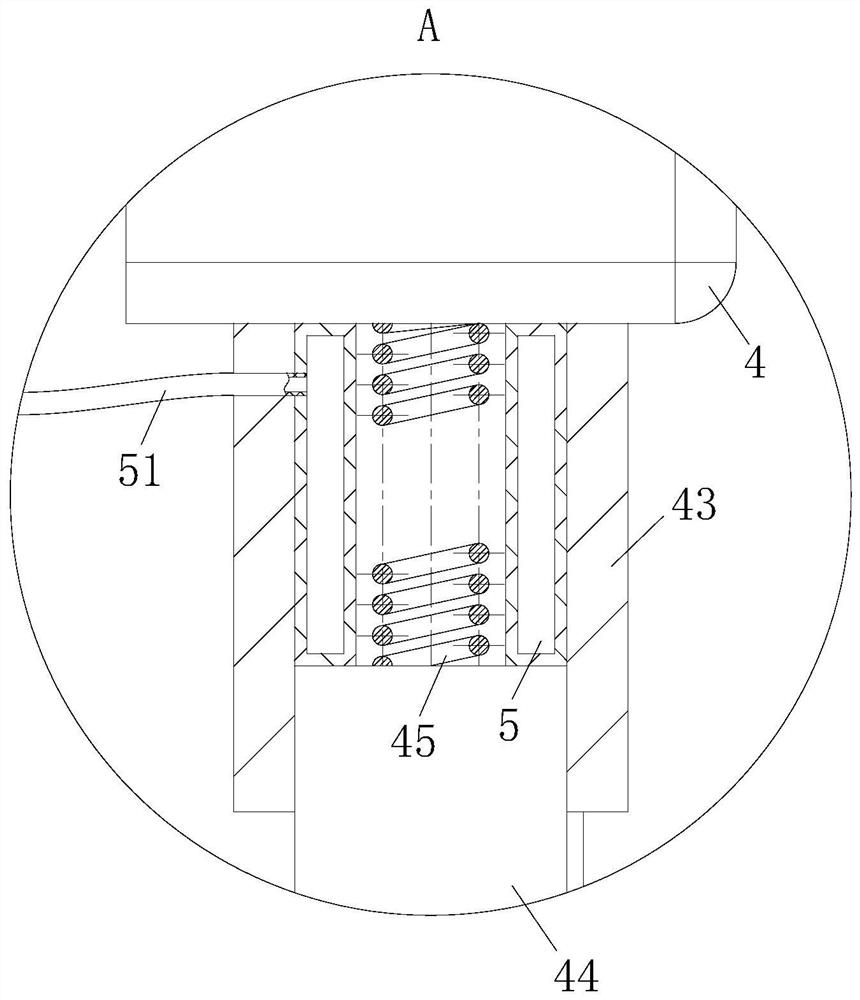

[0027] As an embodiment of the present invention, a group of uniformly distributed reinforcement blocks 6 are fixedly connected to the side wall of the cooling rod 33 along its axial direction, and water flow channels 61 are opened inside the reinforcement blocks 6; The inside of the rod 31 is set as a hollow structure, so that the strength of the rotating rod 31 becomes lower when it is hit by rocks, so that the rotating rod 31 is prone to deformation or damage after a long time of work. At this time, the cooling rod 33 and the rotating rod During the assembly process of the rod 31, the cooling rod 33 can drive the reinforcing block 6 to be inserted into the inside of the rotating rod 31, and at the same time, by setting the length of the reinforcing block 6, the outer end of the reinforcing block 6 can be attached to the inner wall of the rotating rod 31. When the reinforcement block 6 can play a certain supporting effect on the side wall of the rotating rod 31, the working s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com