Diesel engine reversing fan control method

A control method and diesel engine technology, applied in the control of lubricant temperature, coolant flow control, engine cooling, etc., can solve the problems of inability to automatically control the engine, low degree of automation, poor adaptability, etc., to improve automation and intelligence The effect of high level of automation, high degree of automation, and multiple gears

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in combination with specific embodiments. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

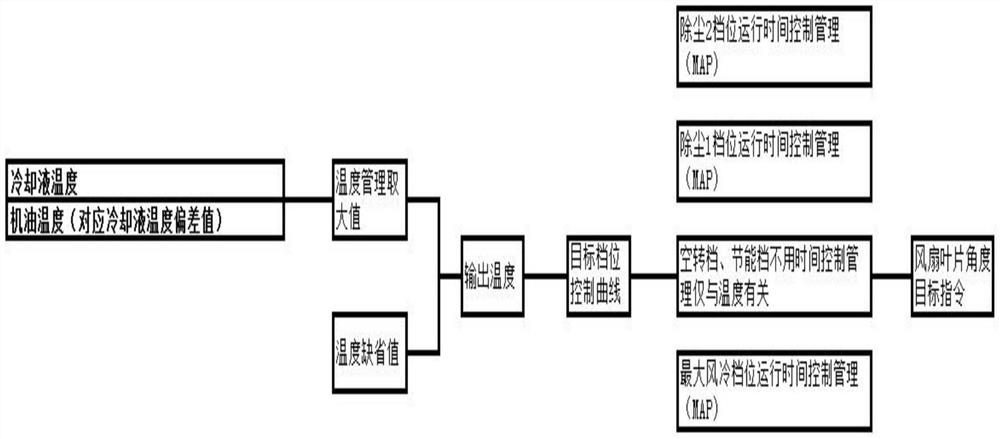

[0014] Such as figure 1 Shown, the control method of described a kind of diesel engine reversing fan is characterized in that: comprise the following steps:

[0015] S1: Temperature calculation management method: take the maximum value of the diesel engine coolant temperature and lubricating oil temperature (oil temperature - deviation value) (considering the difference between the engine oil temperature and coolant temperature, so the difference between the engine oil temperature and the water temperature is compared before comparison ), the set deviation value is 25°C, and the calculated lubricating oil temperature value is: engine oil temperature -25°C; and when one of the two sensors of the water temperature sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com