Supercritical carbon dioxide boiler system for heating recycled flue gas

A carbon dioxide and recirculation technology, applied in steam boilers, lighting and heating equipment, steam generators, etc., can solve the problems of high boiler exhaust gas temperature, poor cooling capacity, and reduced boiler efficiency, and reduce boiler exhaust gas temperature. Avoid the possibility of overtemperature, reduce the effect of the average heat load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

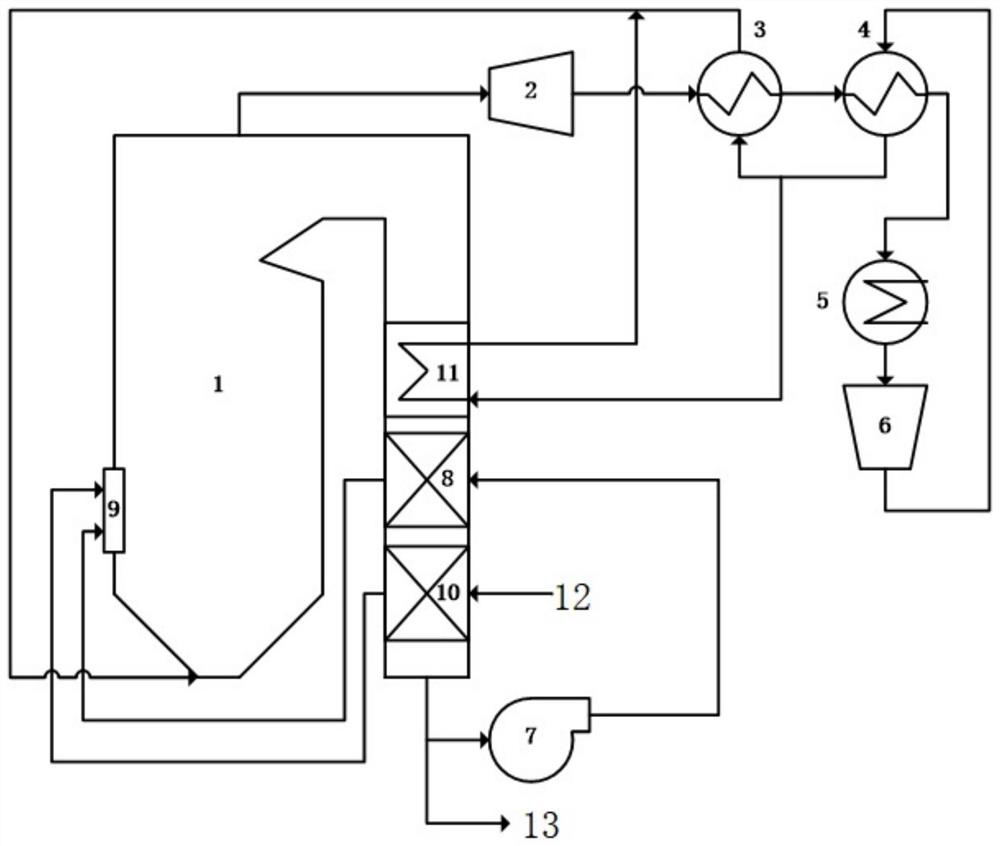

[0027]The supercritical carbon dioxide working medium at the outlet of the heating surface of the supercritical carbon dioxide boiler 1 enters the turbine 2 to do work, and the supercritical carbon dioxide working medium enters the low-pressure side of the high-temperature regenerator 3 and low-temperature regenerator 4 in order to release heat, and then enters the cooling The heat release side of the regenerator 5 continues to cool down, and then enters the compressor 6 to increase the pressure. The low-temperature and high-pressure working fluid enters the high-pressure side of the low-temperature regenerator 4 and absorbs heat. All the way into the split economizer 11 endothermic side to increase the temperature, and then merge with the high-pressure side outlet of the high-temperature regenerator 3, and then enter the inlet of the heating surface of the supercritical carbon dioxide boiler 1 to complete the cycle; the low-temperature regenerator 4 high-pressure side outlet wo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap