Supercritical carbon dioxide boiler system with high-safety hearth heating surface

A carbon dioxide and high-safety technology, which is applied in the direction of steam boilers, steam boiler accessories, steam boiler components, etc., can solve the problem of overheating of metal tube walls, reduce wall temperature, reduce average heat load, and avoid overheating. The effect of Wen's likelihood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the present invention more obvious and understandable, the preferred embodiments are described in detail as follows in conjunction with the accompanying drawings:

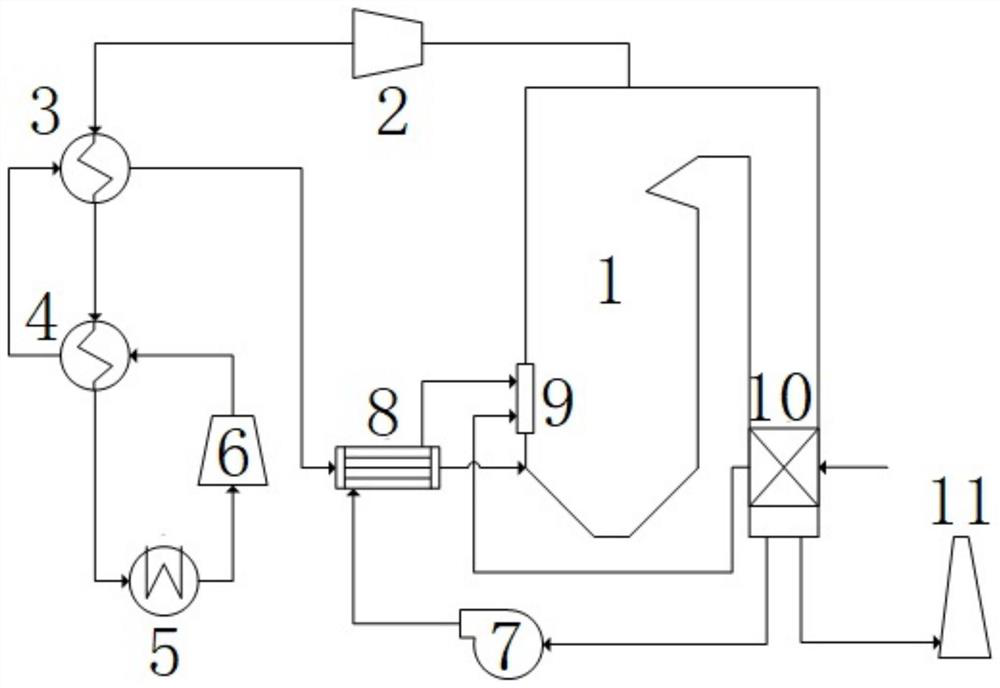

[0019] Such as figure 1 As shown, the present invention provides a supercritical carbon dioxide boiler system with a high-safety furnace heating surface. The boiler system includes a supercritical carbon dioxide boiler 1, a turbine 2, a high-temperature regenerator 3, a low-temperature regenerator 4, and a cooler 5 , compressor 6, recirculation fan 7, recirculation flue gas heater 8, burner 9, air preheater 10 and chimney 11.

[0020] The outlet of the heating surface of the supercritical carbon dioxide boiler 1 is connected to the inlet of the turbine 2, the outlet of the turbine 2 is connected to the inlet of the low-pressure side of the high-temperature regenerator 3, the outlet of the low-pressure side of the high-temperature regenerator 3 is connected to the inlet of the low-pressure si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com