Heat dissipation structure of an energy storage battery box

A technology of heat dissipation structure and energy storage battery, which is applied to structural parts, secondary batteries, battery pack components, etc., can solve the problems of large temperature difference of battery cells, large temperature difference of battery box, affecting battery performance and life, etc. , to achieve the effect of enhancing the base structure of the battery cell, improving the efficiency of heat dissipation and ventilation, and improving the efficiency of ventilation and heat dissipation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

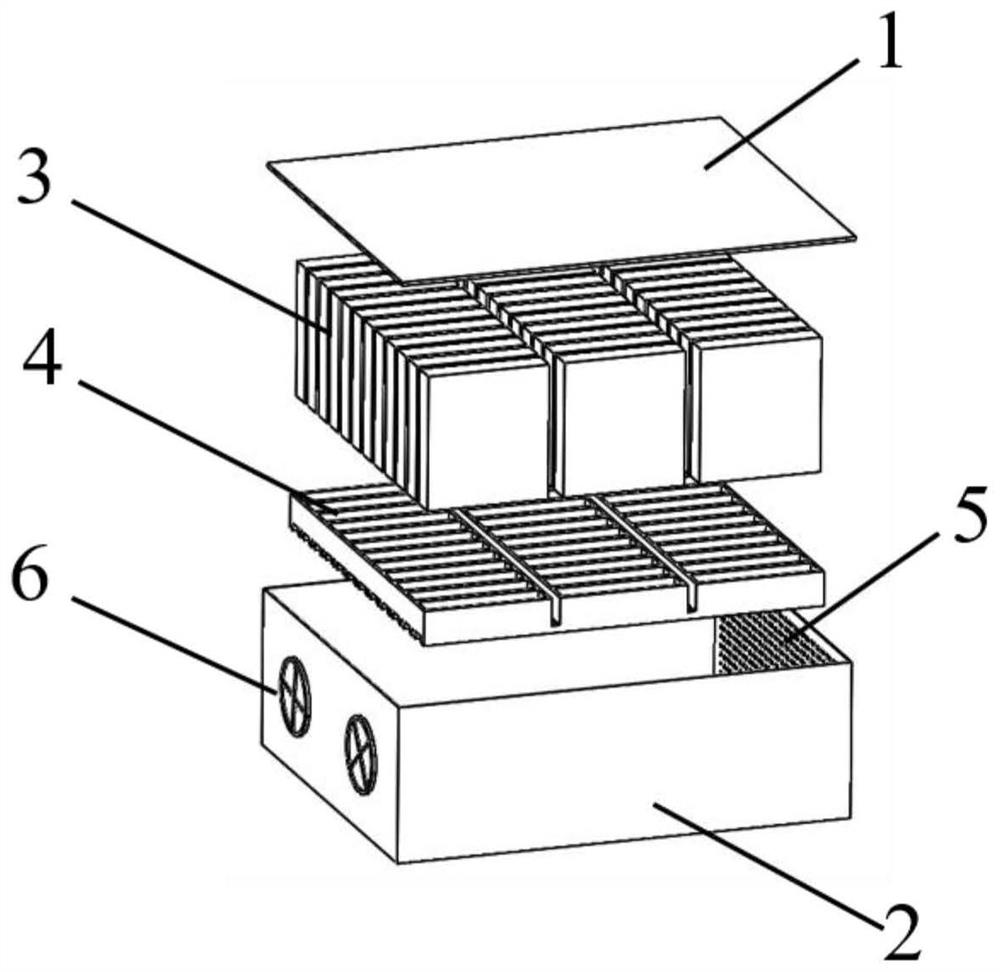

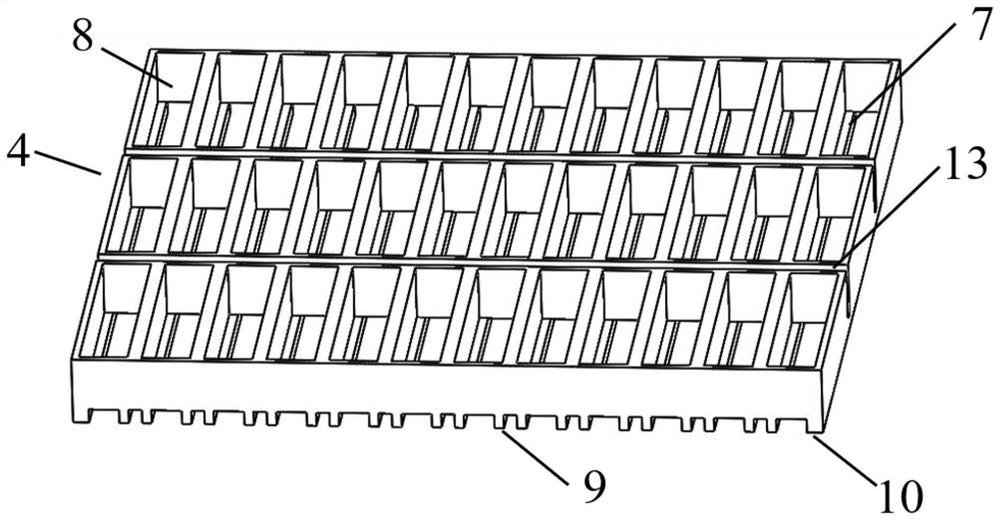

[0048] Such as Figure 1-8 , 10. In a preferred embodiment, a heat dissipation structure of an energy storage battery box includes an upper cover 1 , a casing 2 , a battery cell 3 and a battery cell base 4 located below the battery cell 3 .

[0049] The shell 2 is a hollow cuboid structure with an open upper end, and the size of the shell 2 is 454mm×420mm×173mm;

[0050] The size of the upper cover 1 is the same as the size of the bottom surface of the shell 2, and the upper cover 1 is connected to the shell 2 in a detachable manner;

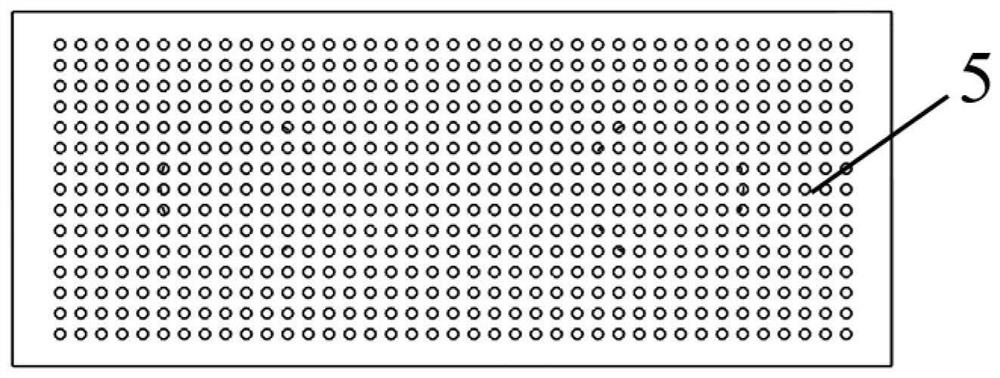

[0051] Two fans 6 are installed on one of the sides of the housing 2, and the other side facing the side is an air inlet 5, and the air inlet 5 is composed of a plurality of densely arranged round holes;

[0052] The fan 6 is used to provide power, and the heat exchanged hot air inside the traction battery box is discharged out of the battery box;

[0053] The air inlet 5 is connected with the air outlet of the air conditioner;

[0054] The bat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com