Stator device, flat electric motor and method for producing a stator device

A motor and flat technology, applied in the manufacture of stator/rotor bodies, electromechanical devices, electric components, etc., can solve the problems of damaging flat motors, contacting rotors, braking, etc., reduce the load on printed wires, and improve life expectancy , The effect of improving the excitation field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

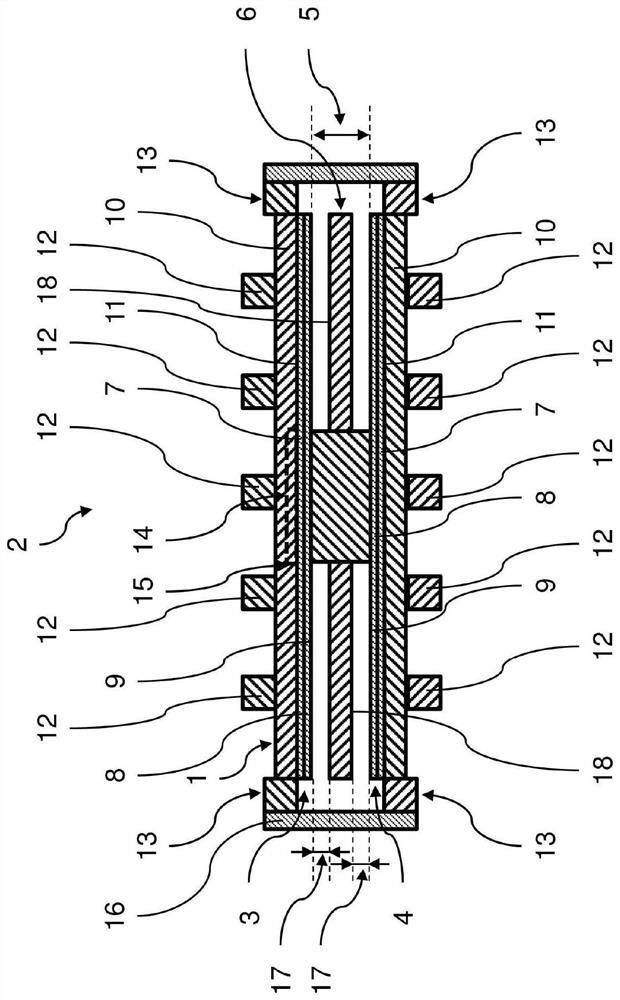

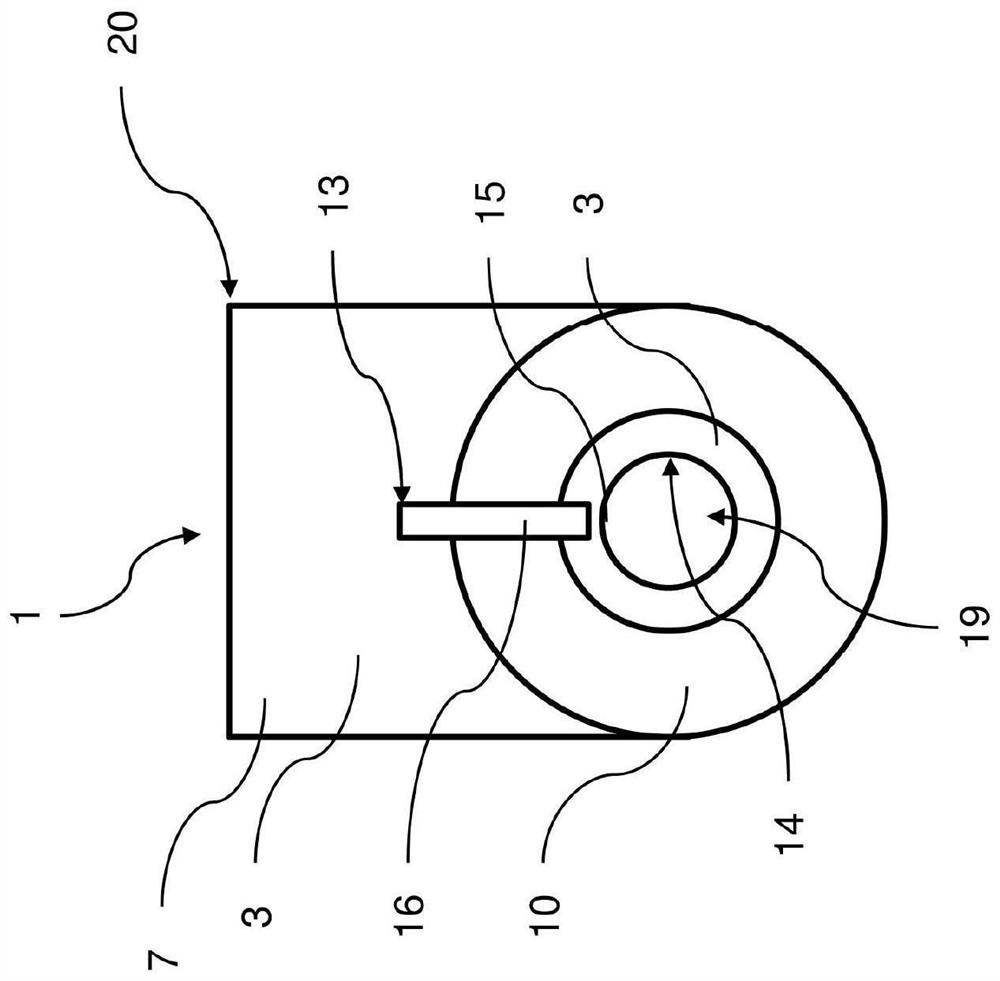

[0053] Parts with the same function and working method are in the Figure 1-7 are marked with the same reference signs.

[0054] figure 1 A preferred embodiment of the flat motor 2 according to the invention is schematically shown in a sectional view. The flat motor 2 has a stator arrangement 1 and a rotor 6 with permanent magnets 18 mounted rotatably on the stator arrangement 1 . The stator arrangement 1 has a first stator side 3 and a second stator side 4 , which are arranged opposite each other forming a constant gap 5 . The rotor 6 is arranged between the first stator side 3 and the second stator side 4 . Air gaps 17 are respectively formed between the first stator side 3 and the rotor 6 and between the second stator side 4 and the rotor 6 .

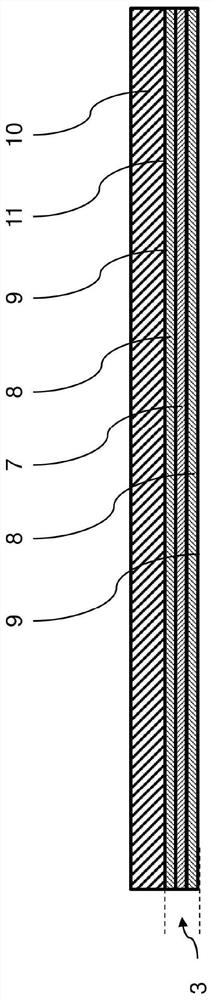

[0055] The first stator side 3 has an electrically insulating carrier substrate 7 with an electrically conductive conductor layer 8 facing the second stator side 4 . Several winding-shaped conductor tracks 9 are formed in the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com