Composition for endowing food with milk flavor, milk fat and product for enhancing aroma through enzymolysis and preparation method of milk fat and product

A composition and product technology, applied in dairy products, cream preparations, food science, etc., can solve the problems of frankincense flavor not being soft enough, flavor not suitable for Chinese consumers, and single flavor type

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

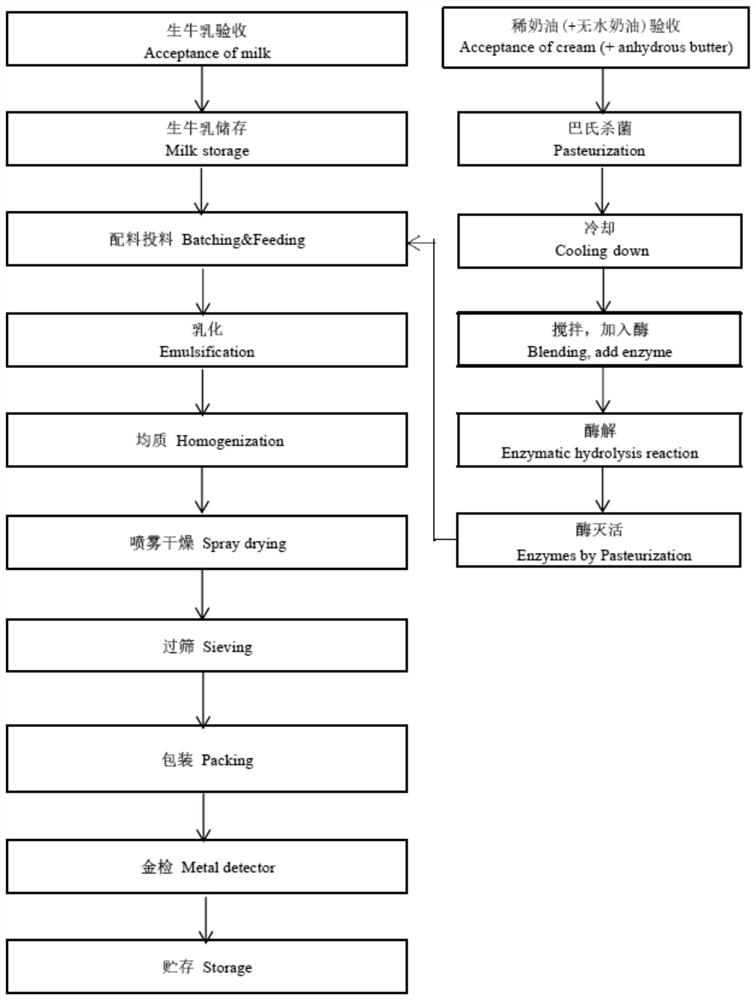

[0093] The present invention also provides a method for preparing an enzymolyzed product with a certain proportion of structurally characteristic aroma components and its products. The preparation method includes the following steps:

[0094] Step (1): Heat the milk fat to 72-90°C, keep it warm for 10-20 minutes, and cool down to 30-50°C for later use;

[0095] Step (2): Add lipase to the material in step (1), stir, and after the pH drops to 5.3-5.4, keep warm at 20-50°C until the pH reaches 4.7-4.8;

[0096] Step (3): Add protease to the material in step (2), stir, and keep warm at 20-50°C until the pH reaches 4.3;

[0097] Step (4): After the reaction is completed, heat the material in step (3) to 80-90°C for 20-40 minutes, then cool and pack to obtain the finished product.

[0098] In some specific embodiments, the milk fat is one or more combinations of cream, cream, and anhydrous cream extracted from cow's milk by centrifugation, with or without homogenization process. ...

Embodiment 1

[0138] 1. Heat 6% natural cream and 10% anhydrous cream to 85°C, keep warm for 10 minutes, then cool down to 45°C for later use.

[0139] 2. Add lipase to the substance in 1, and stir at 70-80rpm / min. After the pH drops to 5.3-5.4, continue to incubate for about 12 hours until the pH reaches 4.7-4.8.

[0140] 3. Add protease to the substance in 2 and stir for about 12 hours until the pH reaches 4.3.

[0141] 4. After the reaction is completed, heat the substance in 3 to 85°C for 20 minutes, then rapidly cool to 45°C within 10 minutes and pack to obtain the finished product.

[0142] The product prepared by the invention is a uniform milky white or milky yellow solid, has a strong smell and taste of natural butter, has no peculiar smell and hala taste, is fine and smooth, and has no visible foreign impurities with normal eyesight.

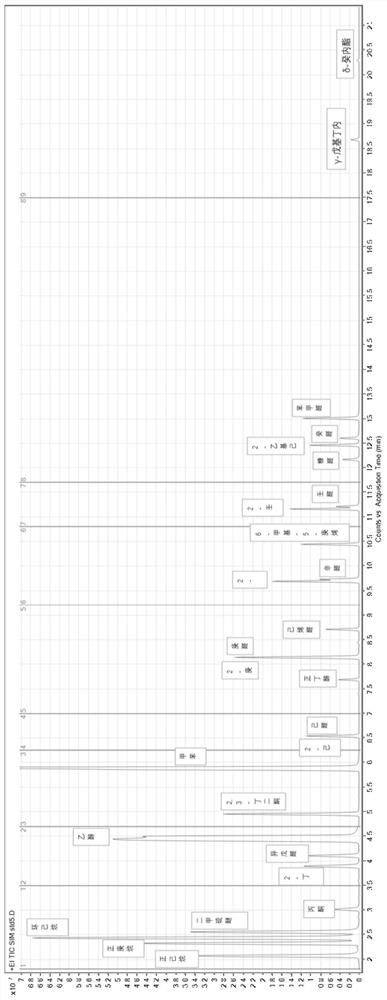

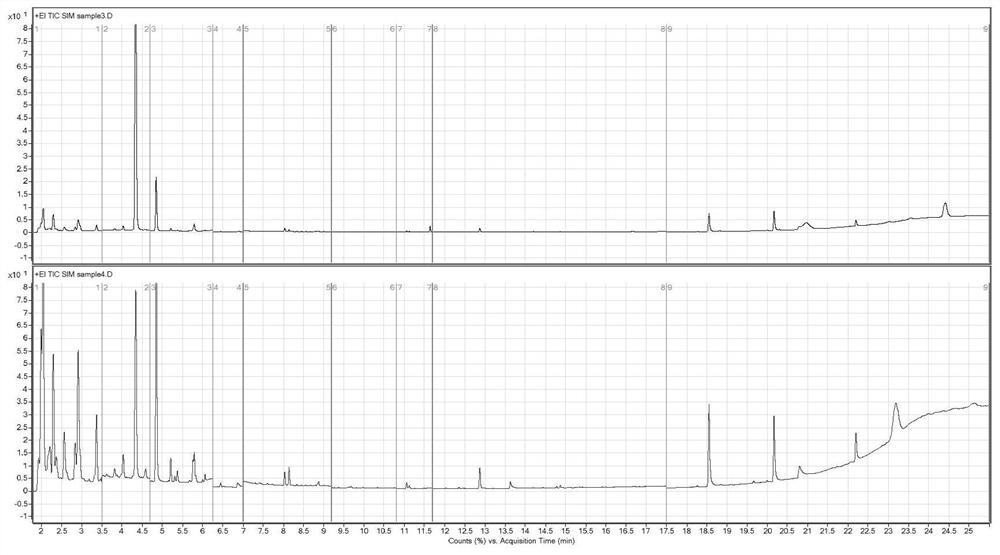

[0143] According to the detection method of flavor substances mentioned above, the indicators of flavor substances contained in this product are s...

Embodiment 2

[0148] 1. Heat the natural cream to 85°C, keep it warm for 10 minutes, then cool down to 45°C for later use.

[0149] 2. Add lipase to the substance in 1, and stir at 70-80rpm / min. After the pH drops to 5.3-5.4, continue to incubate for about 12 hours until the pH reaches 4.7-4.8.

[0150] 3. Add protease to the substance in 2 and stir for about 12 hours until the pH reaches 4.3.

[0151] 4. After the reaction is completed, heat the substance in 3 to 85°C for 20 minutes, then rapidly cool to 45°C within 10 minutes and pack to obtain the finished product.

[0152] The product prepared by the invention is a uniform milky white or milky yellow solid, has a strong smell and taste of natural butter, has no peculiar smell and hala taste, is fine and smooth, and has no visible foreign impurities with normal eyesight.

[0153] According to the detection method of flavor substances mentioned above, the indicators of flavor substances contained in this product are shown in Table 5 belo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com