Novel multi-component medical adhesive spraying device

A spraying device and multi-component technology, applied in the field of medical devices, can solve the problems of long time-consuming, cumbersome operation steps, and affecting the effect of cross-linking and gelling, and achieve good gelling effect and uniform mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

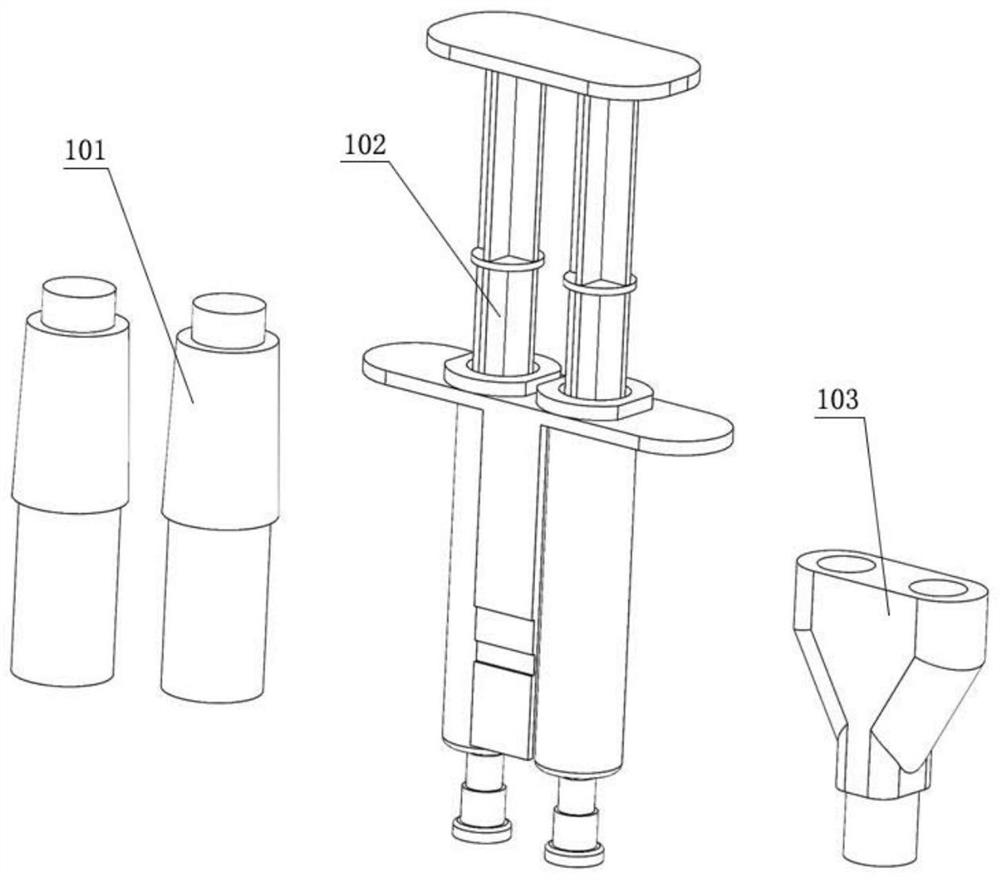

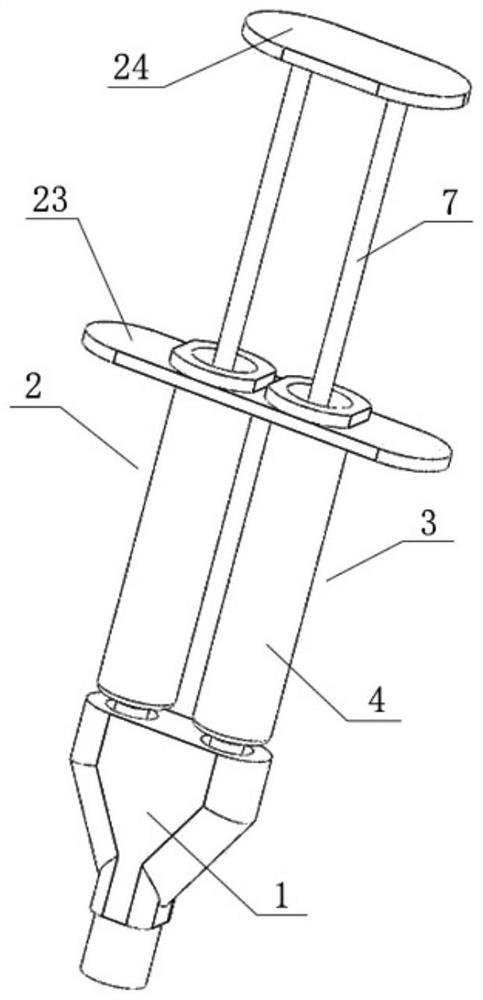

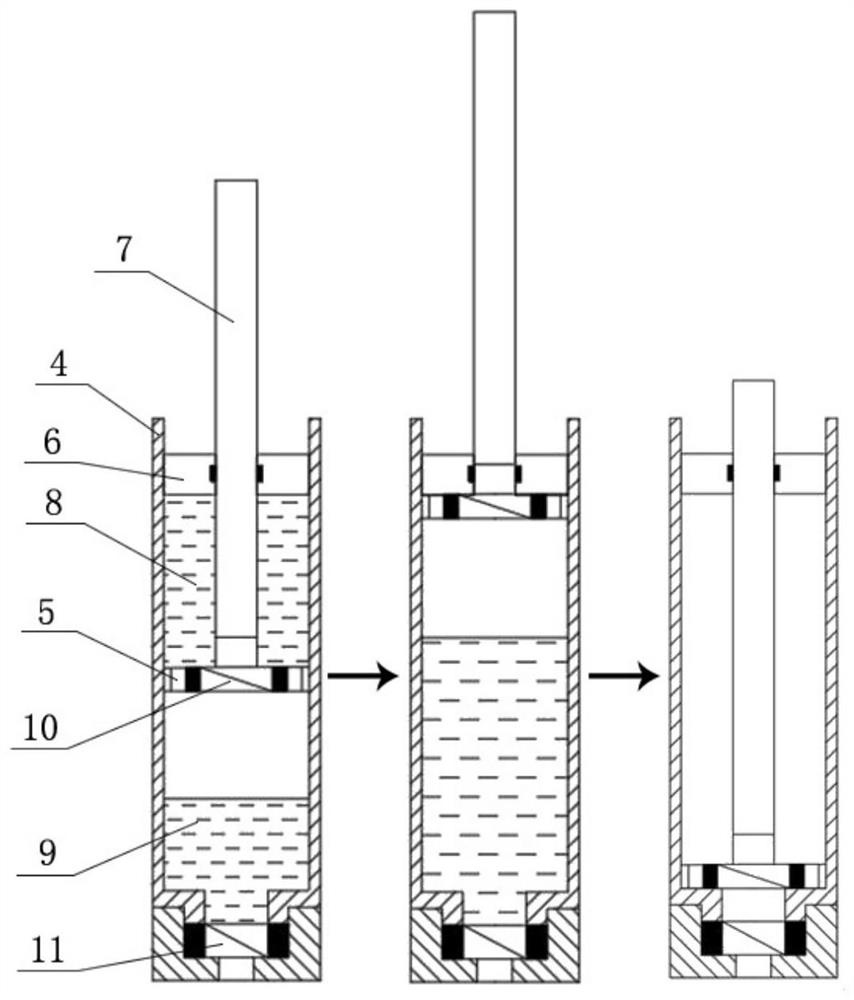

[0034] like figure 2 and image 3Shown, a kind of novel multi-component medical glue spraying device, wherein, comprise spray head 1, the first syringe 2 and the second syringe 3 that are arranged side by side and all are connected with described spray head 1, described first syringe 2 and the second The syringes 3 each include a barrel 4, a piston member 5 that is arranged inside the barrel 4 and can seal and slide along the inner wall of the barrel 4, a blocking member 6 that is arranged at the opening end of the barrel 4, and is used to control the inner wall of the barrel 4. The piston member 5 is a syringe operating rod assembly 7 that seals and slides along the inner wall of the cartridge 4, and the piston member 5 divides the inner space of the cartridge 4 into a first storage chamber between the piston member 5 and the blocking member 6 8 and the second storage chamber 9 between the piston part 5 and the closed end of the cartridge 4, the piston part 5 is provided wi...

Embodiment 2

[0041] This embodiment is similar to Embodiment 1, the difference is that, as Figure 4 As shown, the blocking member 6 is slidingly and sealingly connected to the inner wall of the opening end of the barrel 4, and the syringe operating lever assembly 7 includes a side fixed to the side of the blocking member 6 near the opening end of the barrel 4. The connected operating rod main body 71 and the electromagnet 72 arranged on the side of the blocking member 6 close to the opening end of the barrel 4 and passing through the operating rod main body 71 , the circumference of the piston member 5 An annular iron component 51 is arranged on the side wall. Like this, the first storage chamber 8 is made of the piston part 5, the blocking part 6 and the cartridge 4 wall between them equally, and the second storage chamber 9 is made of the side wall and the bottom wall of the piston part 5 and the cartridge 4 closed ends. constitute. When in use, first connect the power supply of the e...

Embodiment 3

[0043] This embodiment is similar to Embodiment 1, the difference is that, as Figure 5 As shown, the blocking member 6 is fixedly connected to the end surface of the opening end of the barrel 4, one end of the syringe operating rod assembly 7 is fixedly connected to the piston member 5, and the other end extends through the blocking member 6. Out of the open end of the cartridge 4, a spring bottle 12 is arranged in the first storage chamber 8, the mouth of the spring bottle 12 is connected to the first valve 10, and the syringe operating rod assembly 7 It is arc-shaped, the outer arc surface of the syringe operating rod assembly 7 fits with the inner wall of the barrel 4, and the inner arc surface of the syringe operating rod assembly 7 fits with the outer wall of the spring bottle 12, as Image 6 shown. In this way, the first storage chamber 8 for liquid storage is actually the spring bottle 12 , and the second storage chamber 9 is formed by the side wall and the bottom wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com