Sanitary bottom air exhaust low-temperature spray drying device

A drying device and hygienic technology, applied in the direction of spray evaporation, evaporator accessories, etc., can solve the problems of sticky powder hanging pipe, exhaust air temperature drop, high-temperature melting products cannot be continuously produced, etc., to avoid material retention, The effect of eliminating sanitary dead ends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

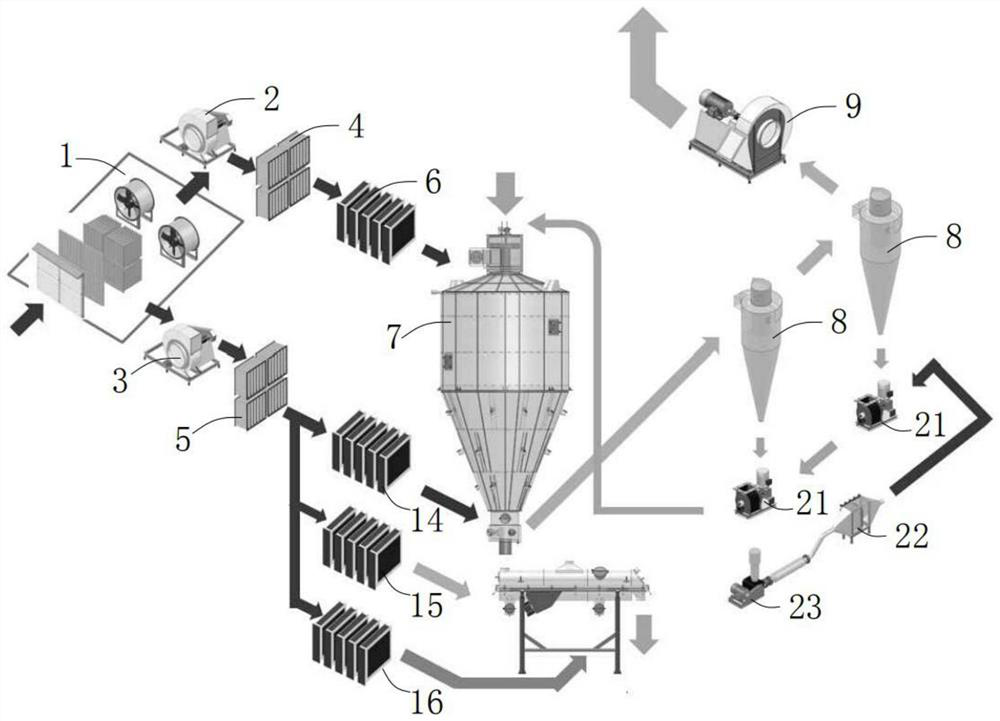

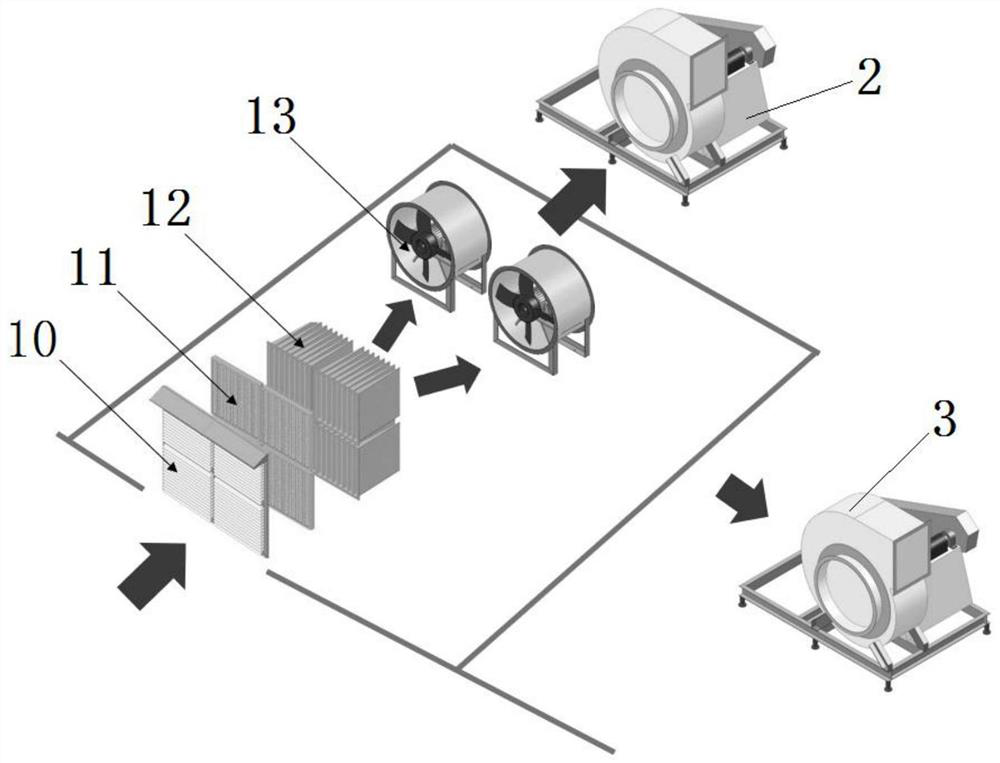

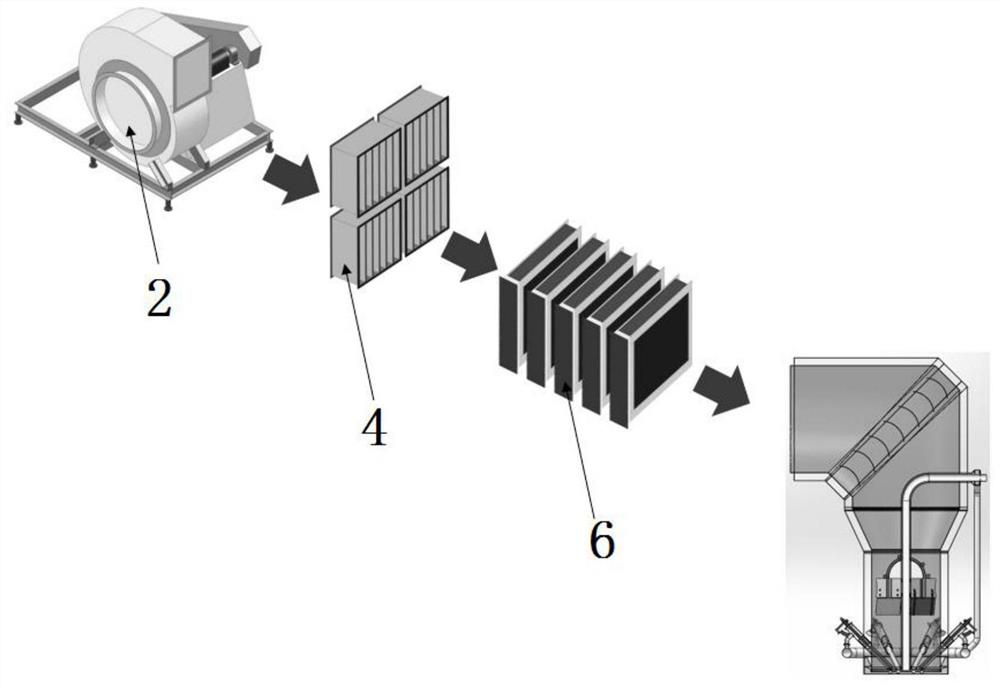

[0022] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

[0023] see Figure 1-6 Description of this embodiment, a sanitary bottom-exhaust low-temperature spray drying device, which includes an air intake chamber 1, a main inlet fan 2, a bed inlet fan 3, a drying tower 7, air heating equipment, dehumidification and heat exchange equipment, and an exhaust mechanism And catch powder mechanism, described drying tower 7 comprises hot blast distributor 17, tower body 18, fixed fluidized bed 19 and vibrating fluidized bed 20, described hot blast distributor 17 links to each other with tower body 18 tops, and described tower body 18 The bottom is connected with the fixed fluidized bed 19, and the fixed fluidized bed 19 is connected with the vibrating fluidized bed 20 through a flexible connection mechanism, and the main inlet fan 2 and the be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com