Oil-water separation device based on air floatation method

An oil-water separation device and air flotation technology, applied in separation methods, liquid separation, chemical instruments and methods, etc., can solve the problems of incomplete oil-water separation, insufficient number of tiny bubbles, and insufficient foam removal, etc. The effect of bubble bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

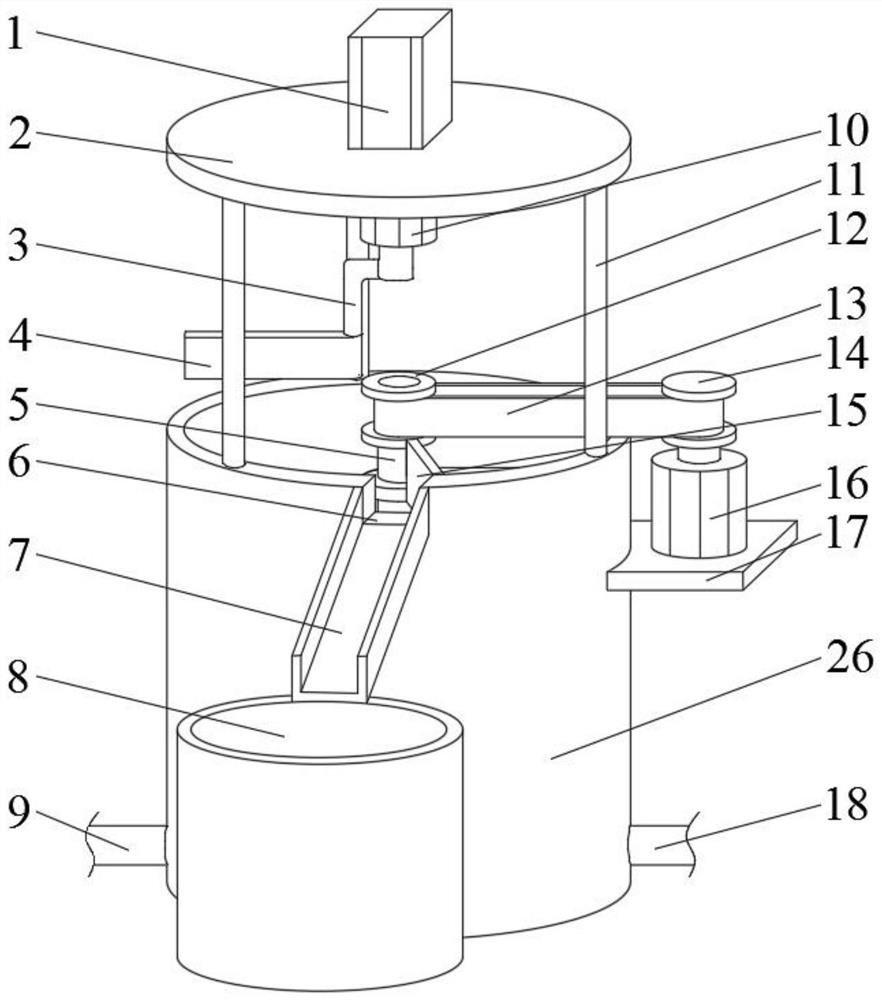

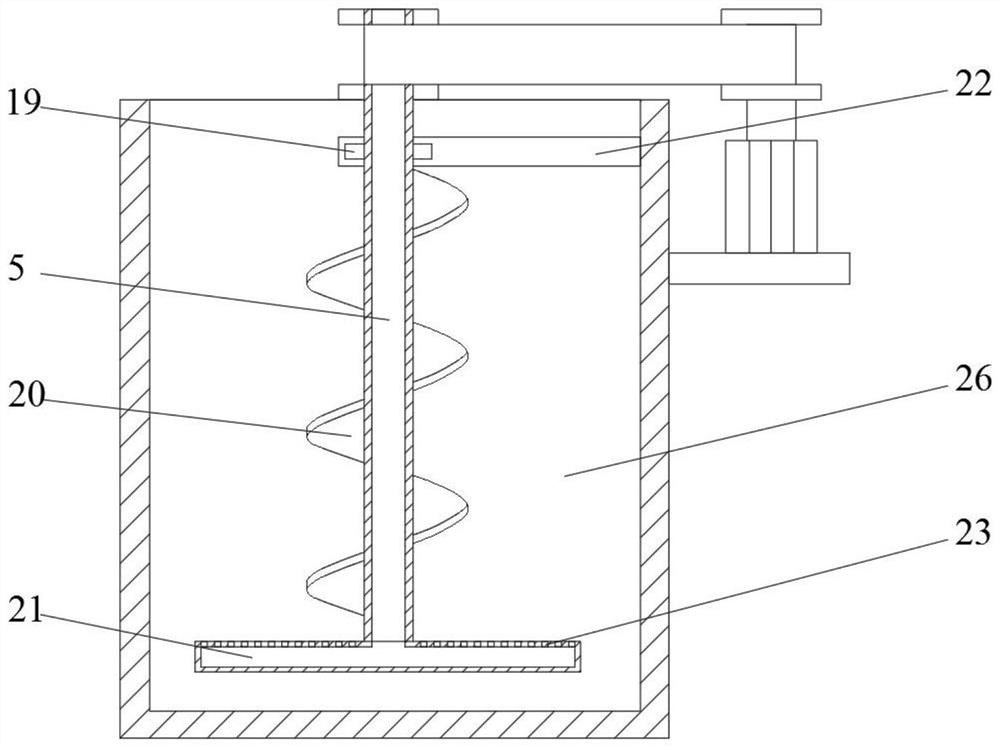

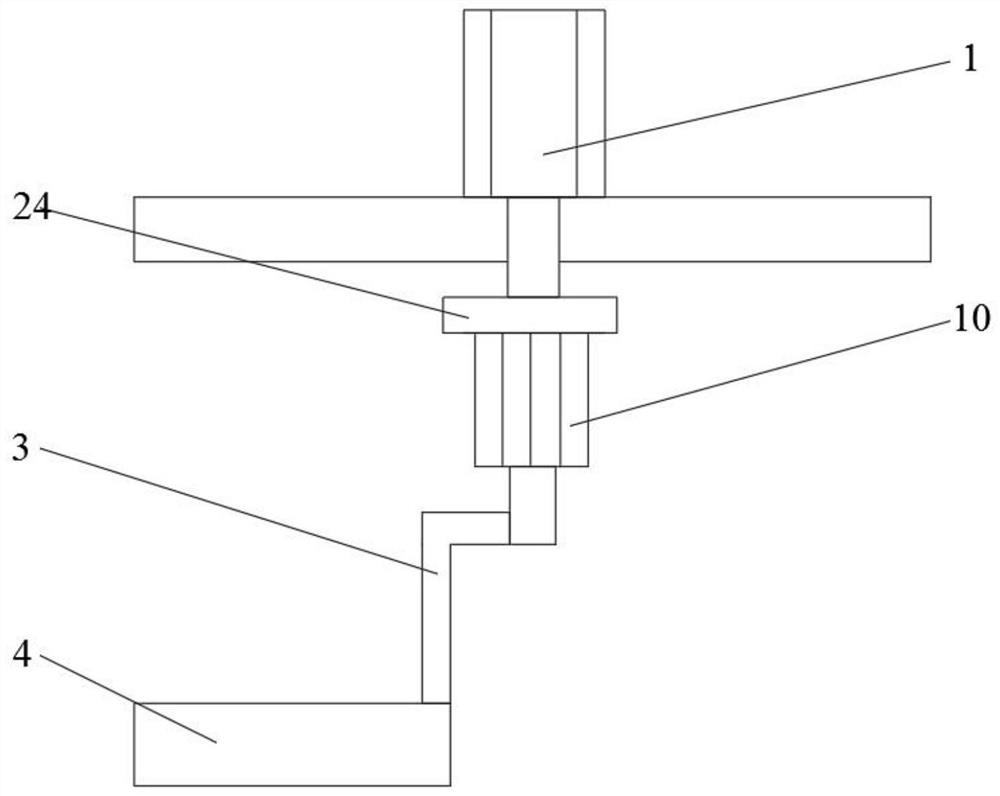

[0029] refer to Figure 1-4 , an oil-water separation device based on the air flotation method, including a separation barrel 26, an oil storage barrel 8 and a top plate 2, an electric telescopic rod 1 is vertically installed at the center of the top of the top plate 2, and the telescopic end of the electric telescopic rod 1 runs through the top plate 2 And with the top plate 2 sliding connection, the bottom end of the telescopic end of the electric telescopic rod 1 is equipped with a second mounting plate 24, and the bottom of the second mounting plate 24 is vertically equipped with a positive and negative motor 10, and the output shaft bottom L of the positive and negative motor 10 The oil scraper 4 is welded on the bottom of the L-shaped rod 3 and the L-shaped rod 3. The positive and negative motor 10 can drive the oil scraper 4 to rotate forward and reverse. When scraping oil, it drives the oil scraper 4 to rotate counterclockwise. Drive the oil scraper 4 to rotate clockwi...

Embodiment 2

[0039] refer to Figure 1-3 And 5, a kind of oil-water separation device based on the air flotation method, comprising a separation barrel 26, an oil storage barrel 8 and a top plate 2, the top center of the top plate 2 is vertically equipped with an electric telescopic rod 1, and the telescopic end of the electric telescopic rod 1 runs through The top plate 2 is also slidably connected with the top plate 2, and the bottom end of the telescopic end of the electric telescopic rod 1 is equipped with a second mounting plate 24, and the bottom of the second mounting plate 24 is vertically equipped with a positive and negative motor 10, and the bottom of the output shaft of the positive and negative motor 10 The end L-shaped rod 3, the bottom end of the L-shaped rod 3 is welded with an oil scraper 4, the middle part of the separation barrel 26 is vertically rotated and connected with a rotating shaft 5, and the separation barrel 26 is provided with a rotating mechanism that drives t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com