Anti-splashing mechanism of stirring pot for preparation of cosmetics made of animal and plant extract

A technology of animal and plant extracts and cosmetics, applied in the direction of mixer accessories, shaking/oscillating/vibrating mixers, mixers, etc., can solve problems such as inability to remove raw materials, splashing, etc., to prevent splashing, improve efficiency, and increase safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

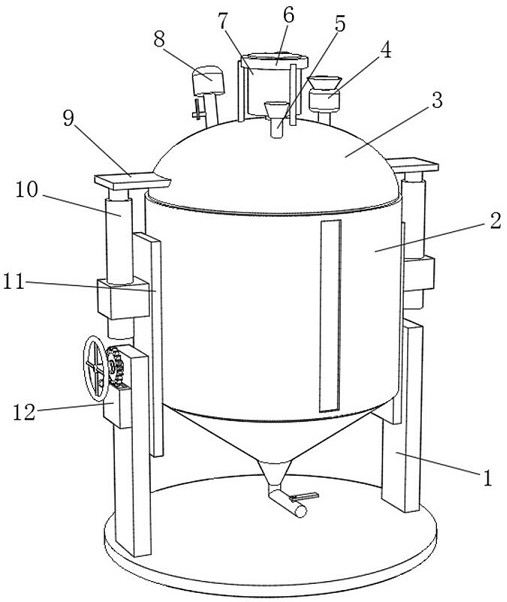

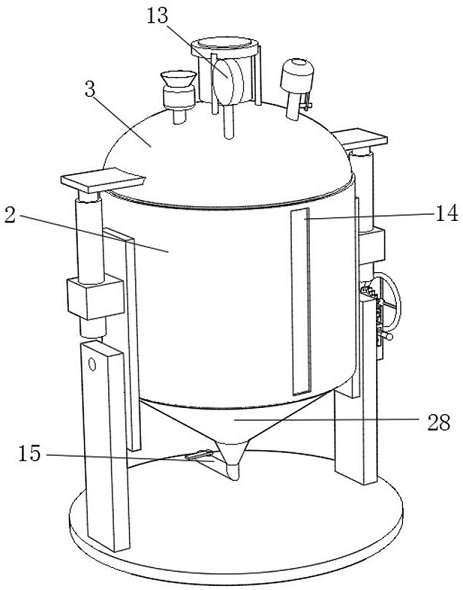

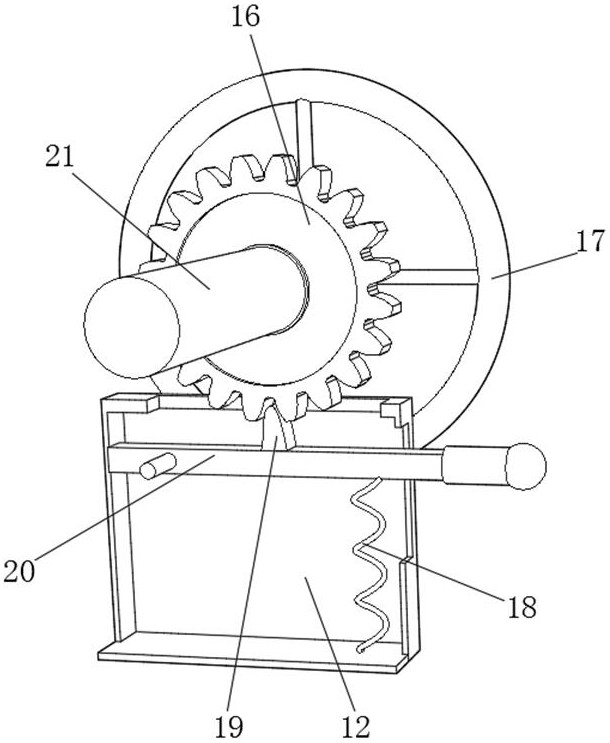

[0032] refer to Figure 1-Figure 4 , an anti-splash mechanism for a stirring pot for preparing animal and plant extract cosmetics, comprising a frame 1, two rotating shafts 21 are rotatably connected to the top of the frame 1, and one side of the rotating shaft 21 is fixed with a rotating plate 11 by bolts, and the rotating plate 11 One side is fixed with a mixing bucket 28 by bolts, the inner wall of one side of the mixing bucket 28 is fixed with a plurality of guide rails 27 by bolts, the inner wall of one side of the mixing bucket 28 is fixed with a material removal plate 26 by bolts, and the upper surface of the material removal plate 26 is set There are multiple scraping grooves 24, the top of the mixing bucket 28 is fixed with a top cover 3 by bolts, the top of the top cover 3 is fixed with an organic base 6 by bolts, one side of the base 6 is fixed with a motor 7 by bolts, and the output shaft of the motor 7 One end passes through the top cover 3 and is fixed with a sti...

Embodiment 2

[0036] refer to Figure 5-Figure 6 , an anti-splash mechanism of a stirring pot for preparing animal and plant extract cosmetics, one end of the discharge pipe 15 is fixed with a flat pressure tube 29 by bolts, and the inner wall of one side of the flat pressure tube 29 is fixed with a limiting groove 30 by bolts. One side of the groove 30 is slidably connected with a baffle 31, one side of the limiting groove 30 is fixed with a third spring 37 by bolts, one end of the discharge pipe 15 is fixed with a fixed pipe 38 by bolts, and one side of the fixed pipe 38 is slidably connected There is a retaining frame 34, one side of the fixed pipe 38 is fixed with a support 32 by bolts, the top of the support 32 is rotatably connected with a pressing rod 33, and the two ends of the pressing rod 33 are respectively in contact with the baffle plate 31 and the retaining frame 34, Through the cooperative use of the baffle plate 31 and the material retaining frame 34, when the material comes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com