Grinding machine for pipe grinding with single-side chamfering and grinding function

A grinding machine, unilateral technology, applied in the direction of machine tools suitable for grinding workpiece edges, cleaning methods using tools, cleaning methods and utensils, etc., can solve operator burns, debris splashing, poor heat dissipation of drive motors, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

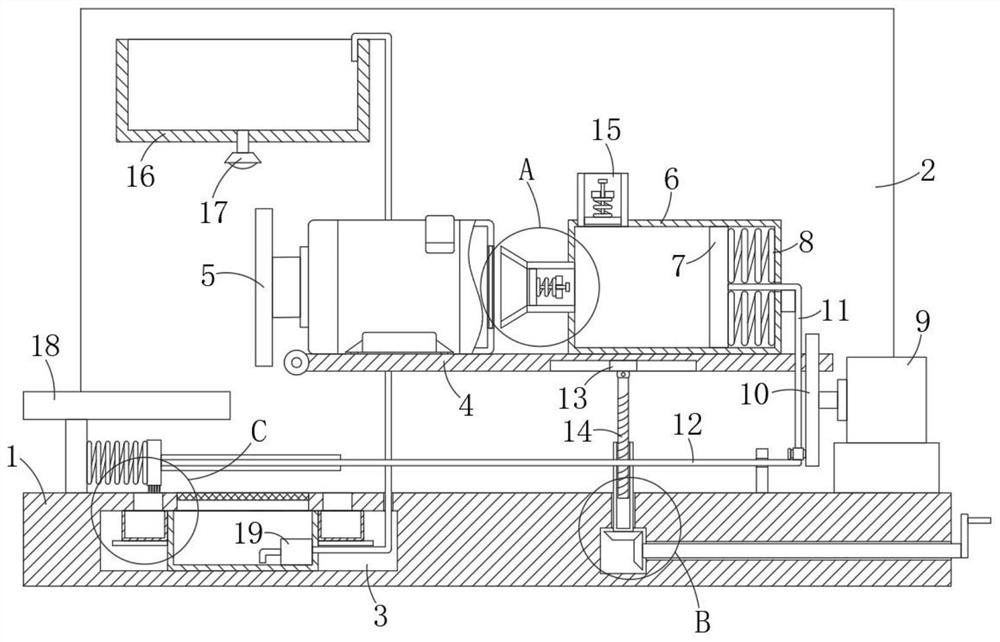

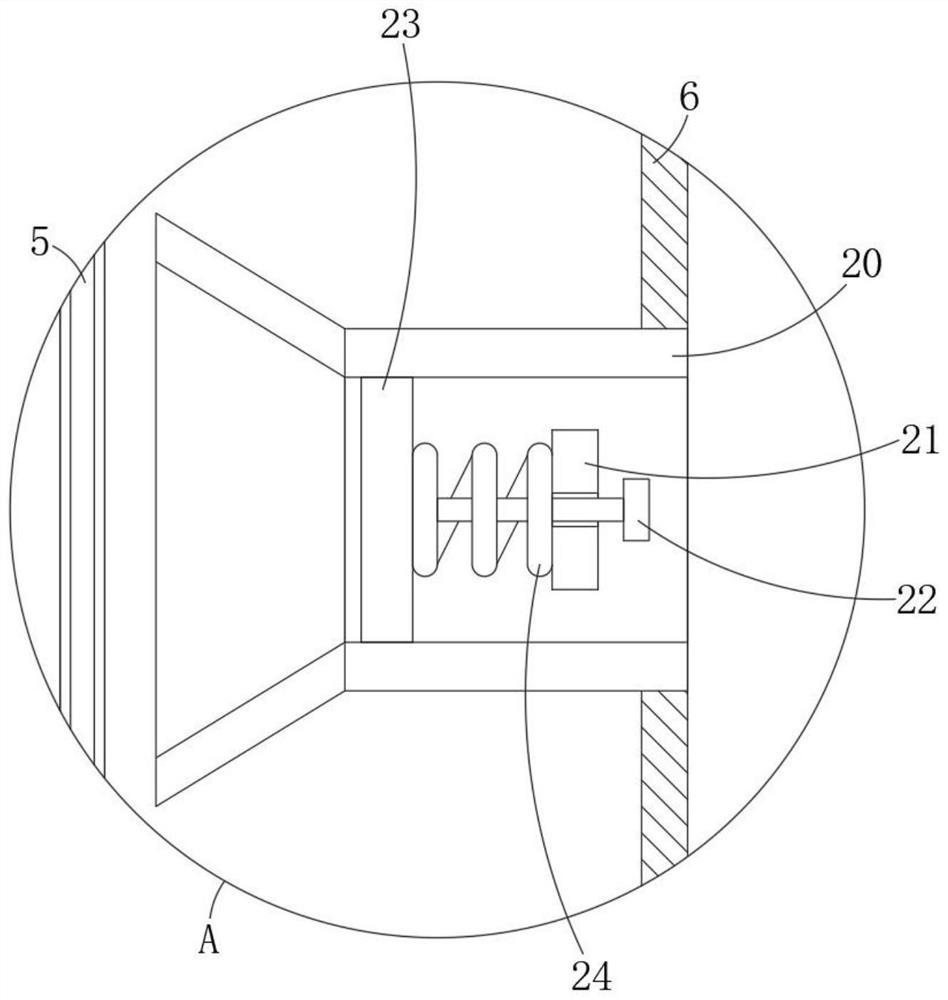

[0024] refer to Figure 1-4 , a grinding machine for grinding pipes and having the function of unilateral chamfering and grinding, comprising a base 1, a mounting plate 2 is fixedly installed on the top of the base 1, and a spraying mechanism is arranged on the mounting plate 2, and the spraying mechanism includes a fixed mounting on the mounting plate The water storage basin 16 on the front side wall of the plate 2, the bottom of the water storage basin 16 is fixedly installed with a nozzle 17 communicating with the interior thereof;

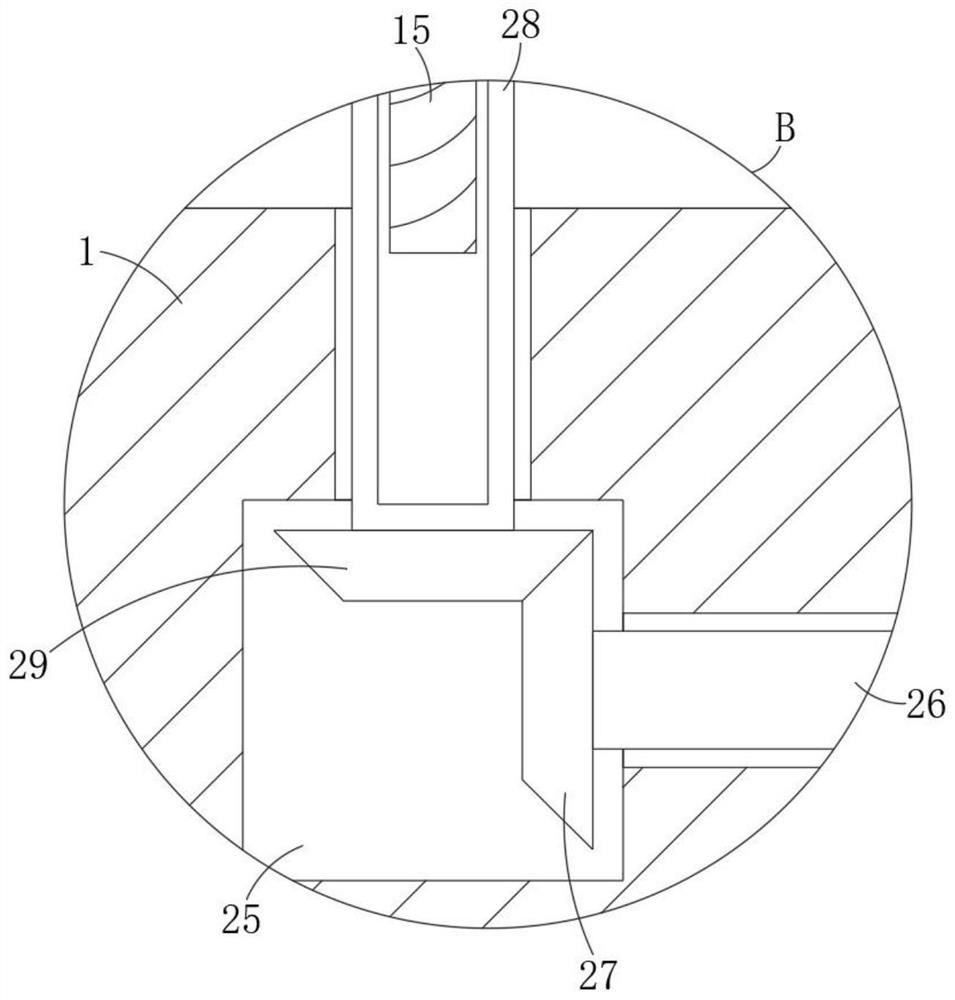

[0025] The base 1 is provided with a placement groove 3 and an installation cavity 25, and the inner top of the placement groove 3 i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap