Angle adjustable fiber product cutting machine

A fiber product and cutting machine technology, which is applied in the field of fiber product processing, can solve the problems of inconvenient adjustment of the angle of fiber products, dust pollution of the environment, and damage to the health of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

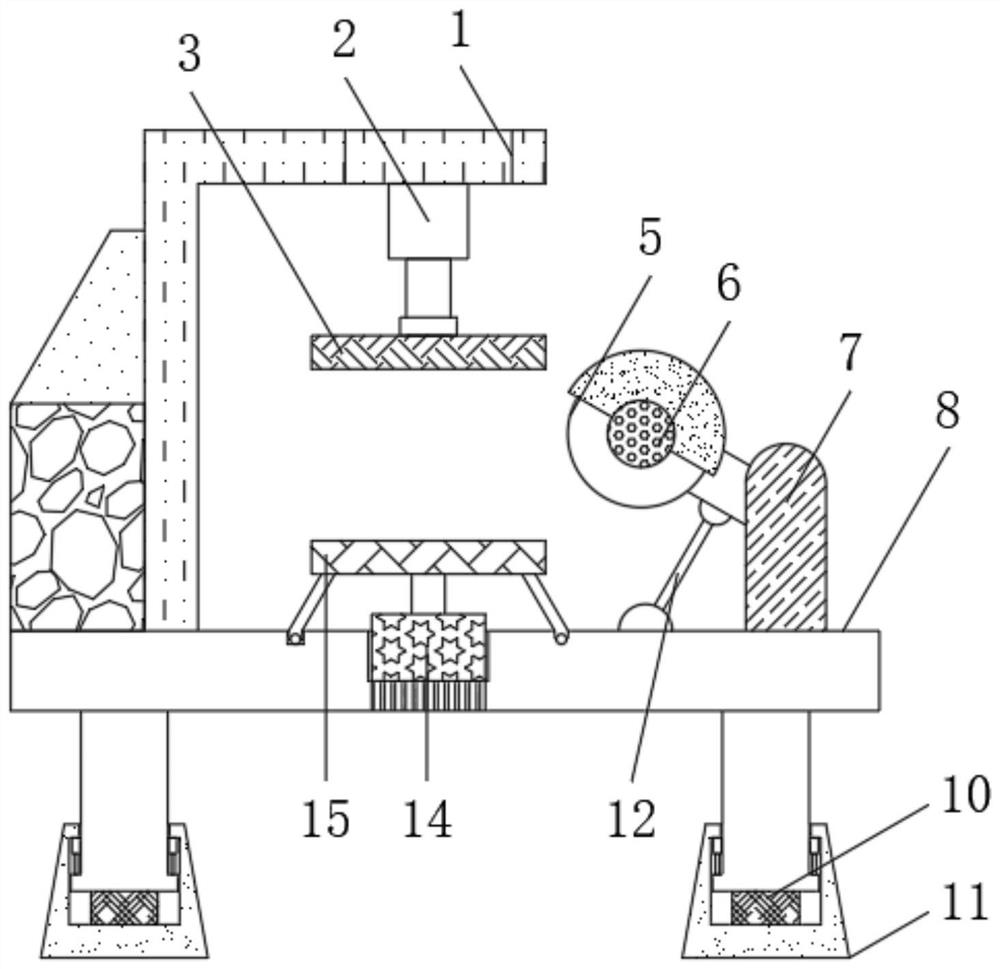

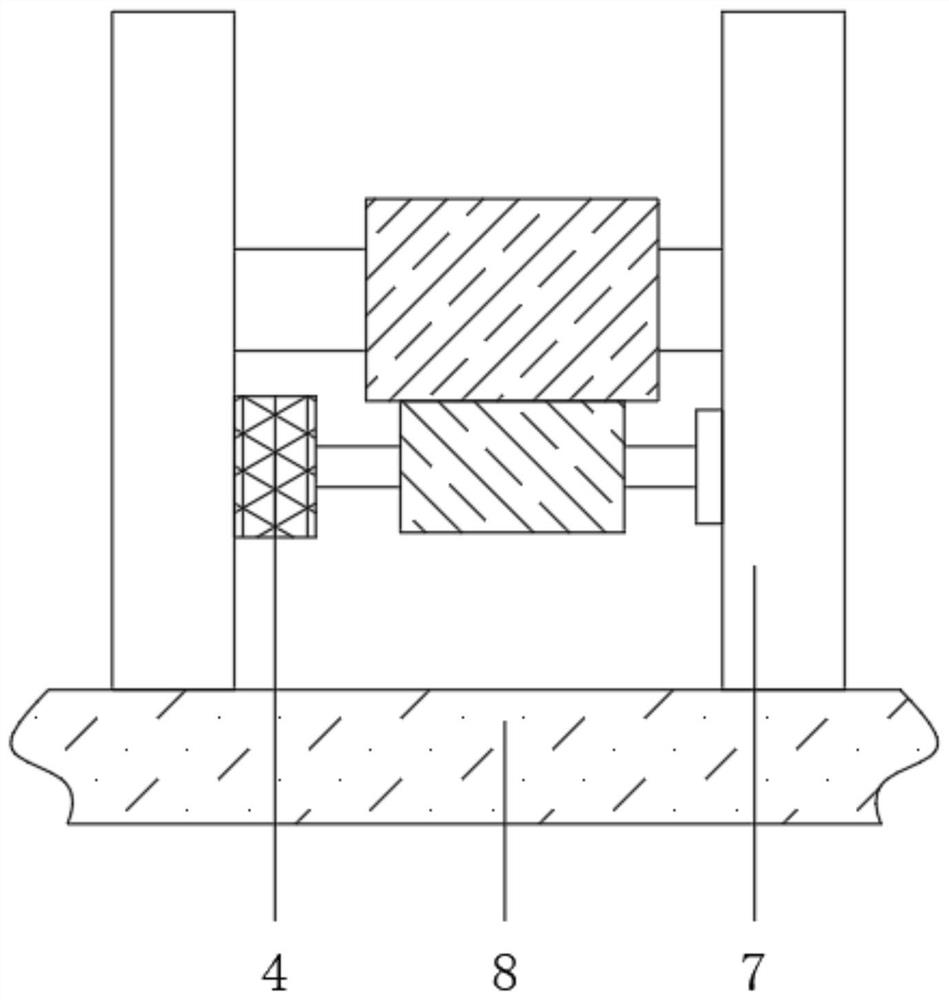

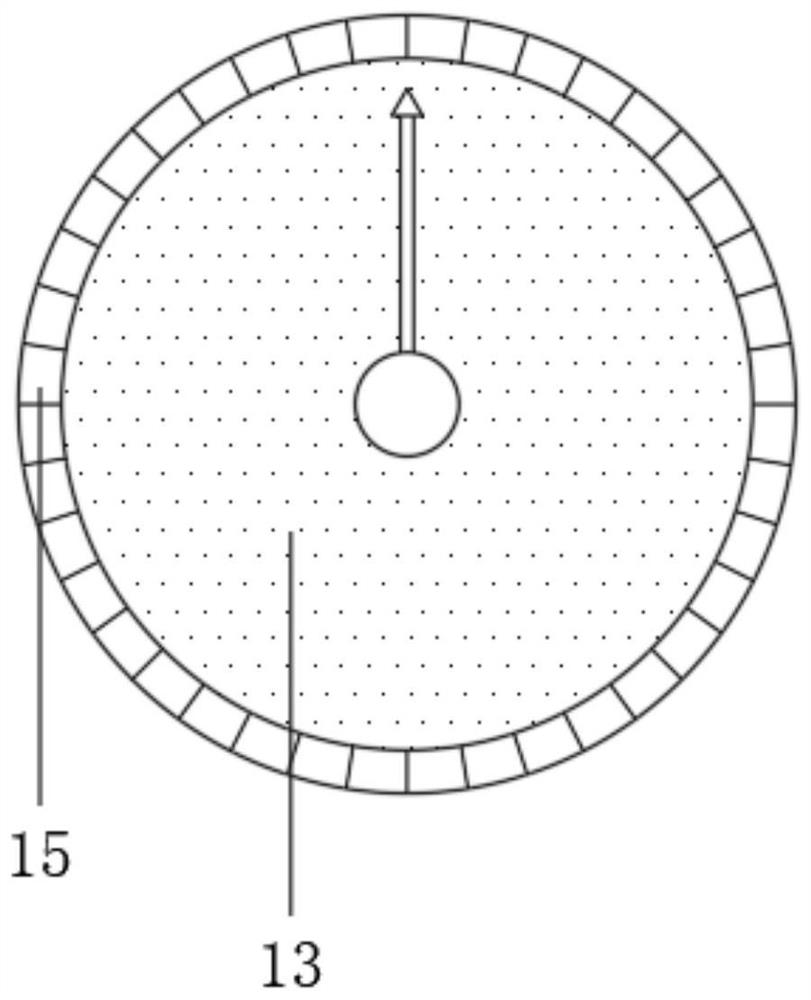

[0027] refer to Figure 1-4 , an angle-adjustable fiber product cutting machine, including a base 8, an L-shaped side plate 1 is installed on one side of the top outer wall of the base 8 through bolts, and a hydraulic column 2 is fixedly installed on the outer wall of the bottom end of the L-shaped side plate 1, and the hydraulic column 2 The bottom end is rotatably connected with the pressure plate 3, the middle of the base 8 is inlaid with a third motor 14, and the upper end of the third motor 14 is installed with a cutting table 13 through the rotating shaft, and the outer wall of the cutting table 13 is rotated and socketed with an angle plate 15 , the other two ends of the outer wall at the top of the base 8 are installed with a fixed plate 7 through bolts, and the upper ends of the inner walls of the two fixed plates 7 are fixedly installed with a rotating shaft, and the outer wall of the outer wall of the rotating shaft is fixedly sleeved with a gear rod. The first moto...

Embodiment 2

[0037] refer to Figure 5 , an angle-adjustable fiber product cutting machine, further, a ring groove 16 is opened at the top of the base 8, and a negative pressure collection tank 17 is installed at the bottom of the base 8 through bolts.

[0038] Working principle: Dust, debris, etc. are attracted to the negative pressure collection tank 17 through the ring groove 16, so as to avoid serious pollution of the environment by debris and dust and damage to the health of workers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com