New energy automobile battery bearing system, replacement tool and battery replacement method

A new energy vehicle and battery replacement technology, which is applied to electric vehicles, charging stations, vehicle maintenance, etc., can solve the problems of difficult replacement, operator injury, and low investment, and achieve the effect of saving battery replacement time and reducing battery replacement costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

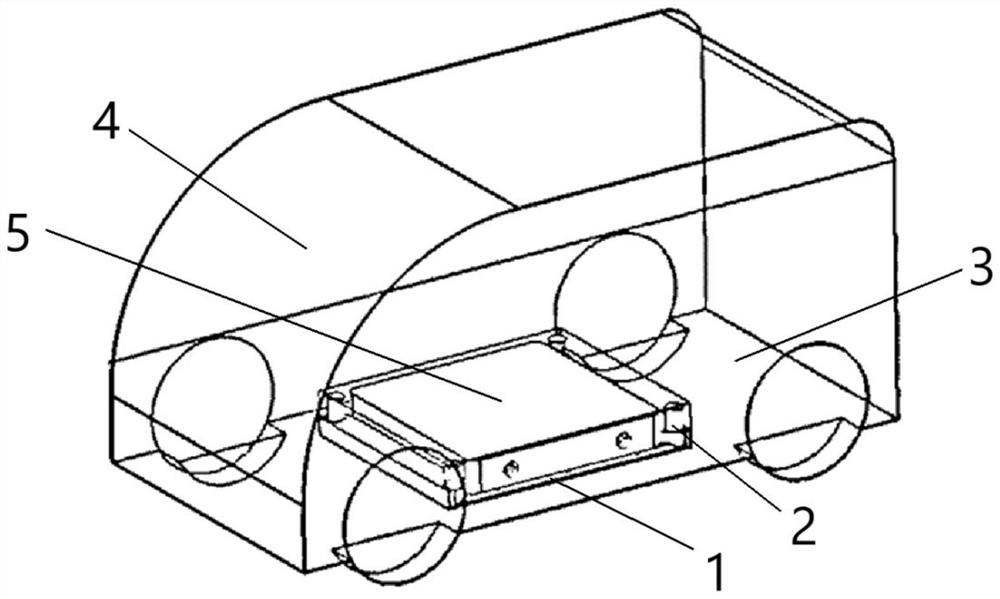

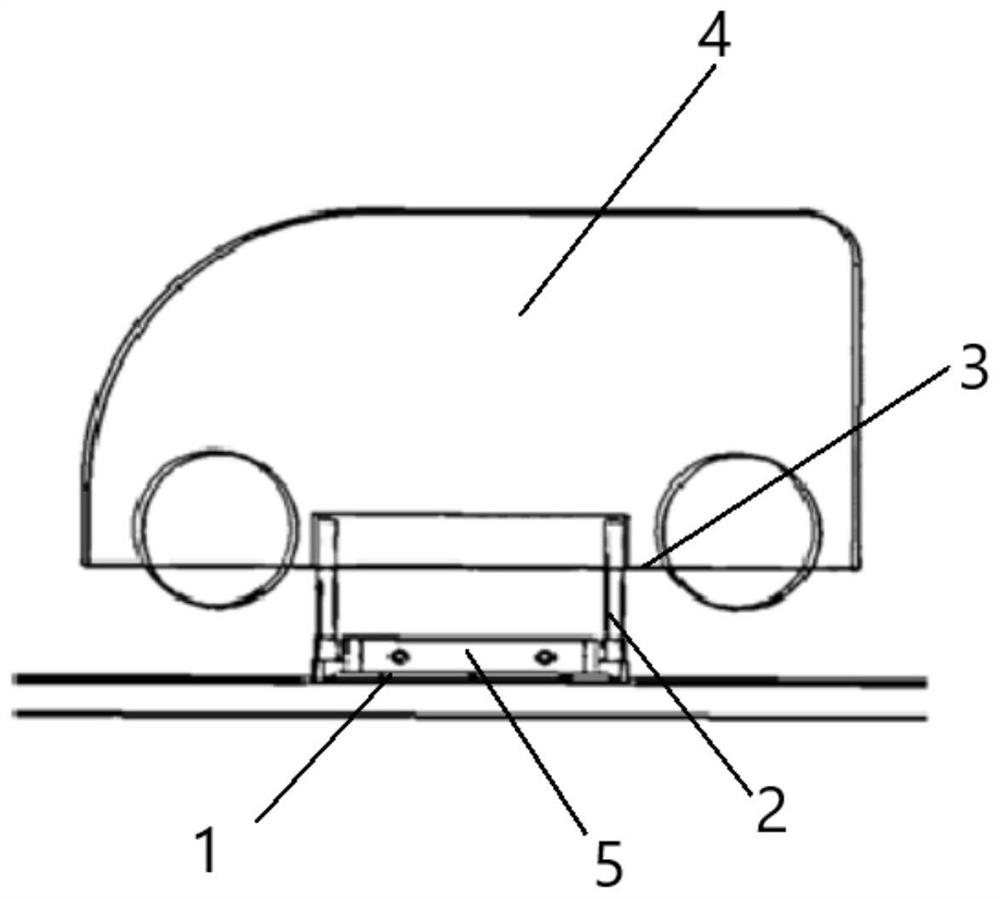

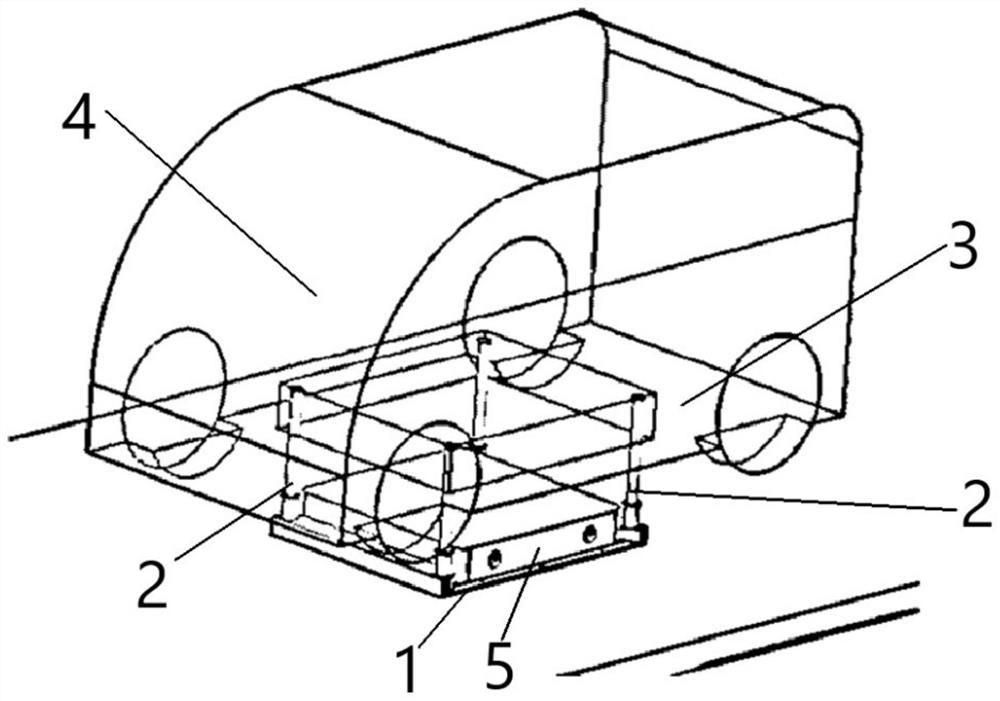

[0043] figure 1 It is a schematic structural diagram of a new energy vehicle battery carrying system according to an embodiment of the present invention. figure 2 is based on figure 1 The schematic diagram of the structure of the battery carrying system of the new energy vehicle shown in the battery replacement state. Combine below Figure 1-Figure 2A new energy vehicle battery carrying system of the present invention will be described in detail. A new energy vehicle battery carrying system provided by the present invention may generally include: a tray 1 , a lifting rod 2 and a control unit (not shown in the figure). The control unit can be the driving computer (ECU for short) of the vehicle 4 or other control modules, and the control unit can also be a control chip specially set for the new energy vehicle battery carrying system. The control unit is electrically connected with the lifting rod 2 for controlling the elongation or contraction of the lifting rod 2 . The pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com