Telescopic side wall assembly and telescopic lift car

A side wall assembly and assembly technology, applied in the field of elevators, can solve the problems of inconvenient construction on site, waste of resources, size mismatch, etc., and achieve the effects of convenient construction, convenient building construction, and convenient use and installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be further described below in combination with specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

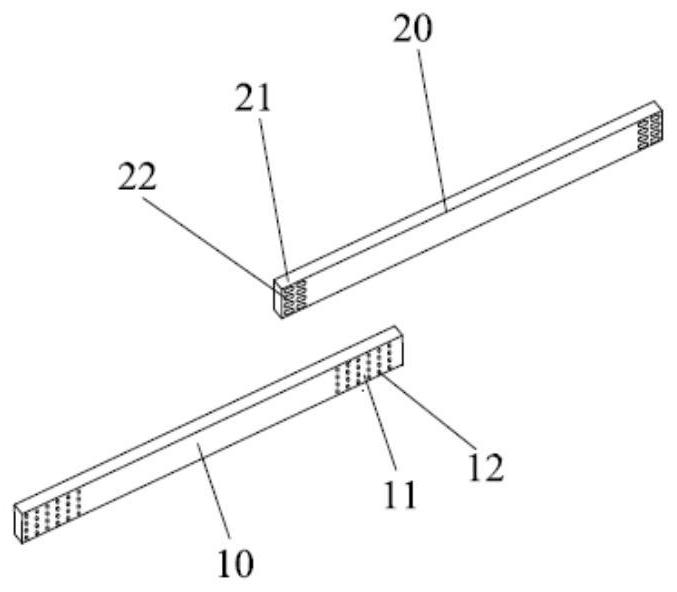

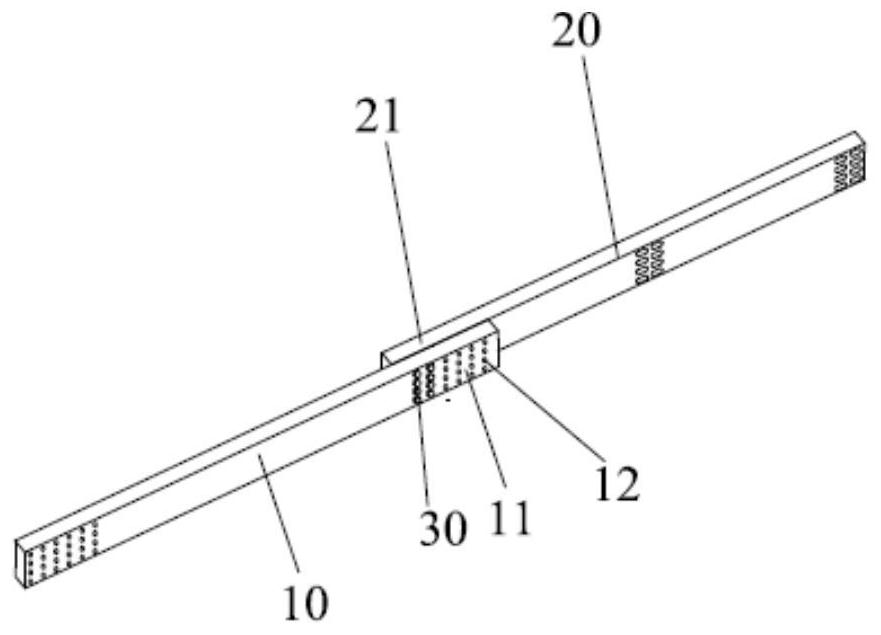

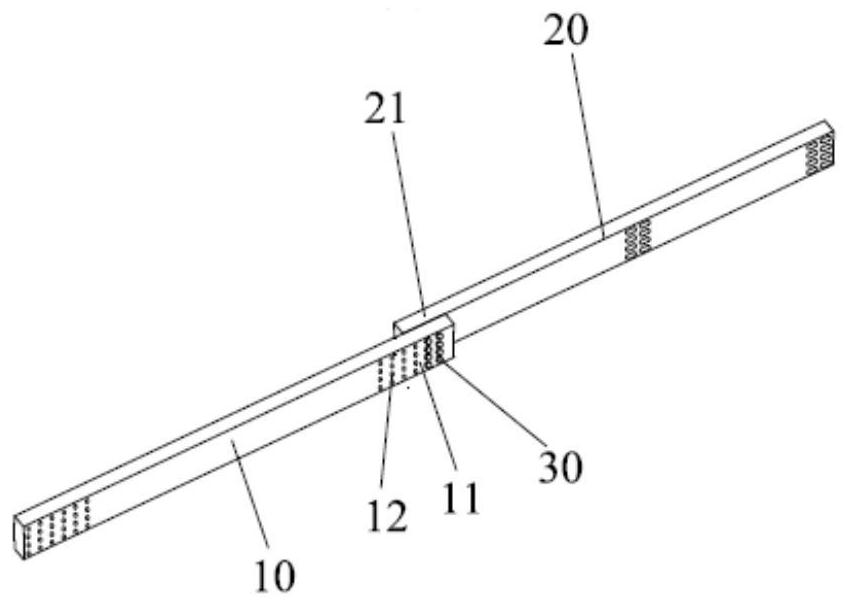

[0070] refer to Figure 1A , Figure 1B with Figure 1C , a panel telescopic connection structure, including a first panel 10 and a second panel 20, the first panel 10 has a first connection end 11, and the first connection end 11 is provided with N rows and M rows of indefinite Connection holes 12, N≧1, M≧2; the second plate 20 has a second connection end 21, and the second connection end 21 is provided with N rows and P rows of connection holes 22 at equal intervals, M≧P≧1; The first connection end 11 and the second connection end 12 are partially overlapped together to form a superposition area, and the connection holes 22 in the superposition area are all aligned with a corresponding indeterminate connection hole 12 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com