Tower top roller seamless wrapping cloth structure of continuous hot galvanizing production line

A production line, hot-dip galvanizing technology, applied in the direction of hot-dip galvanizing process, coating, metal material coating process, etc., can solve the problems of strip steel horizontal periodic imprints, etc., to improve the rolling capacity, improve the overall utilization rate, and improve the overall Use the effect of increased intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0031]Example 1

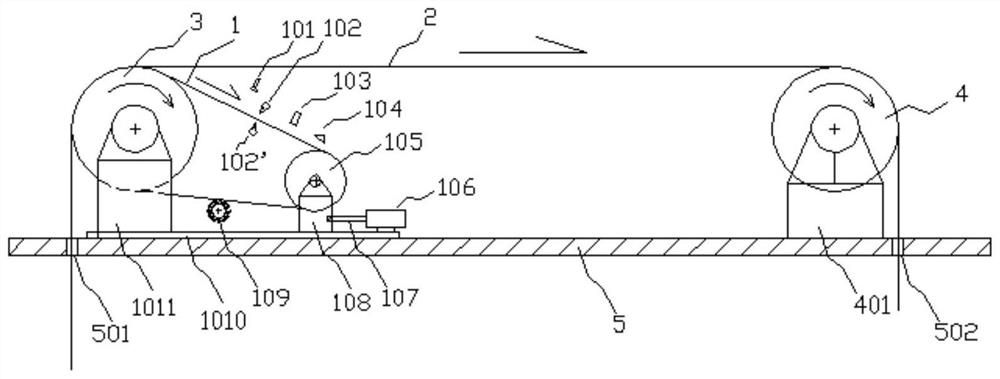

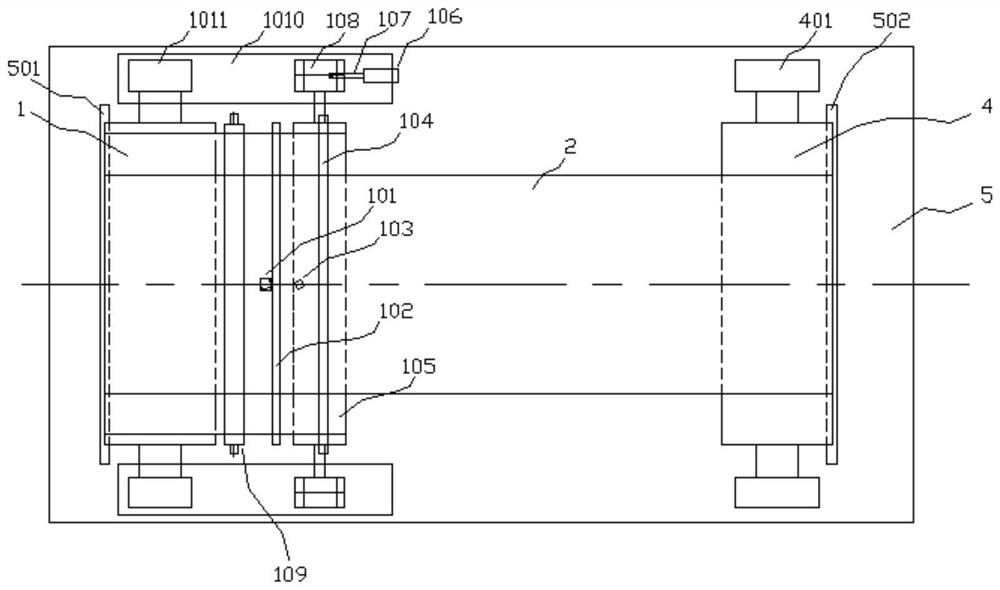

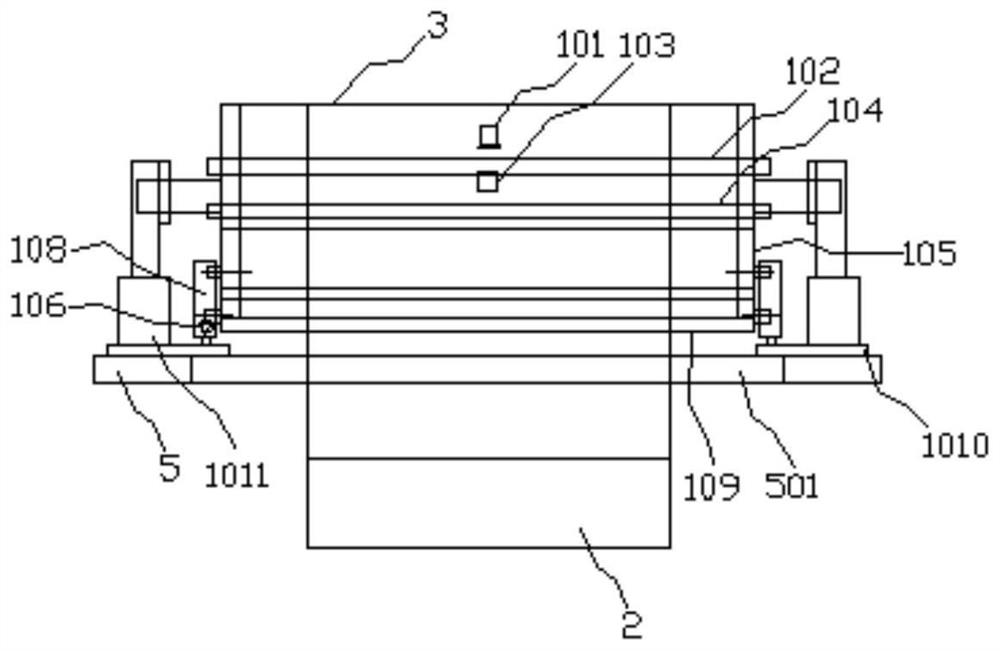

[0032]This embodiment provides a continuous hot-dip galvanizing production line tower top roller seamless wrapping structure, including a cooling tower top installation platform 5 and a tower top turning front roller 3 arranged on the cooling tower top installation platform 5 to steer the steel belt 2 and The top turning rear roller 4 is characterized in that the top turning front roller 3 is sleeved with a seamless wrapper 1, and the cooling tower top mounting platform 5 is provided with a use that cooperates with the tower top turning front roller 3 The tension adjustment roller assembly for the tension of the seamless wrapping 1, the cooling tower top installation platform 5 is also provided with a wrapping correction component that cooperates with the seamless wrapping 1, a wrapping cooling component, a wrapping slag cleaning component and Packing damage detection components.

[0033]The tower top turning front roller 3 and the tower top turning rear roller 4 are res...

Example Embodiment

[0036]Example 2

[0037]This embodiment is further optimized on the basis of embodiment 1, specifically:

[0038]The seamless wrapping cloth 1 includes multiple layers of wrapping cloth bonded by an adhesive. The number of bonding layers of the seamless wrapping cloth 1 is at least 2 layers, and the number of layers increases in an even number. The end-to-end connection of the same layer of wrapping cloth is inclined at 45 °Angle bonding.

[0039]Seamless wrapping 1 referenceFigure 4 The bonding angle and bonding method of the seamless cloth covering of the top rollerFigure 5 The schematic diagram after the seamless wrapping of the tower top roller is bonded as a reference, the seamless wrapping 1 uses a multilayer wrapping fabric bonded by an adhesive. The number of bonding layers is at least two, and the number of layers increases in an even number, with an inclination of 45° For corner bonding, the corresponding number of bonding layers is the same. After the seamless wrapping 1 is bonded...

Example Embodiment

[0040]Example 3

[0041]This embodiment is further optimized on the basis of embodiment 1 or 2, specifically:

[0042]The tension adjustment roller assembly includes a tension adjustment roller 105 and a tension adjustment roller mounting base 108 for installing the tension adjustment roller 105. The diameter of the tension adjustment roller 105 is smaller than the diameter of the front turning roller 3 at the top of the tower. The adjustment roller 105 is located between the tower top turning front roller 3 and the tower top turning rear roller 4, the cooling tower top installation platform 5 is provided with a roller installation platform 1010, and the top steering front roller base 1011 is fixedly installed on the roller installation platform 1010 , The tension adjustment roller installation base 108 is movably installed on the roller installation platform 1010, and the roller installation platform 1010 is provided with a tension adjustment roller 105 to adjust the distance between the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap