Rolling friction support for supporting columns of underground subway station

A rolling friction, subway station technology, used in engine components, underwater structures, engine lubrication, etc., can solve the collapse and damage of the structural system, increase the dynamic axial compression ratio of the support column, weaken the shear deformation resistance, etc. problems, to achieve the effect of reducing damage, small rolling friction resistance, and reducing relative horizontal deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

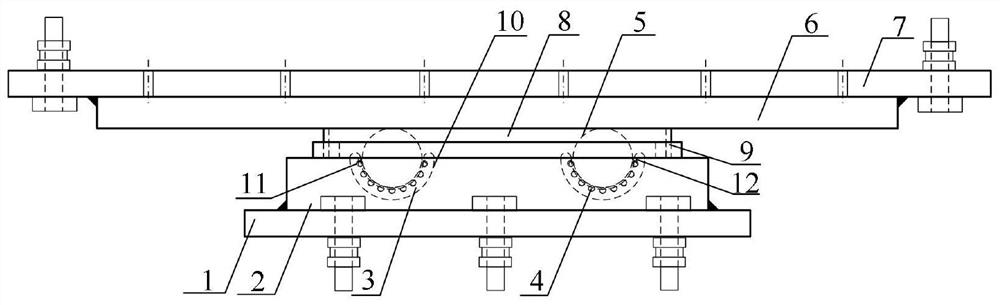

[0023] Such as figure 1 As shown, a rolling friction support for support columns of underground subway stations is characterized in that the rolling friction support is mainly composed of a lower connecting plate (1), a lower seat plate (2), a stainless steel circular arc plate (3) , ball (4), steel rod (5), upper seat plate (6), upper connecting plate (7) and dust cover (8).

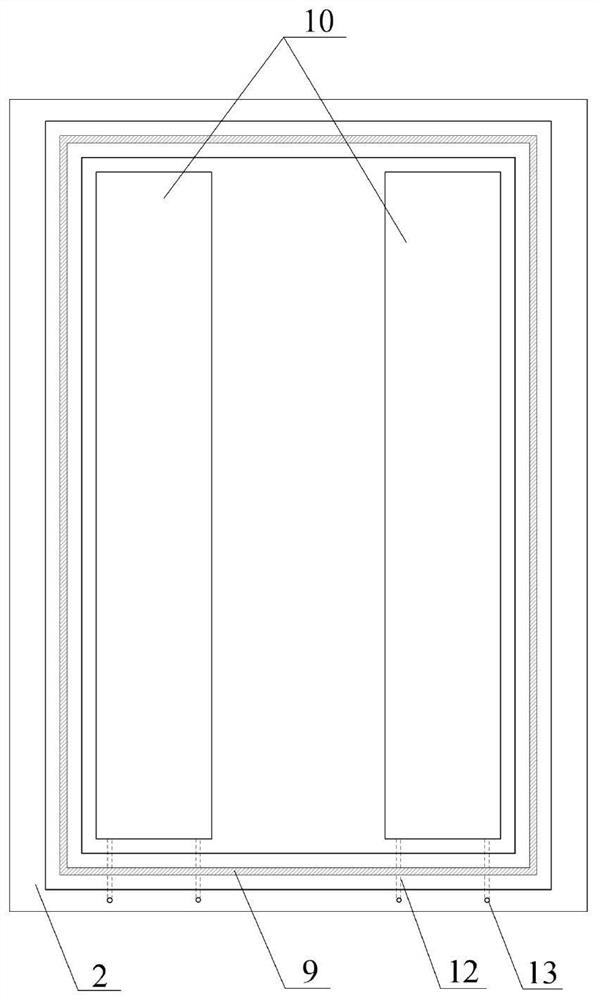

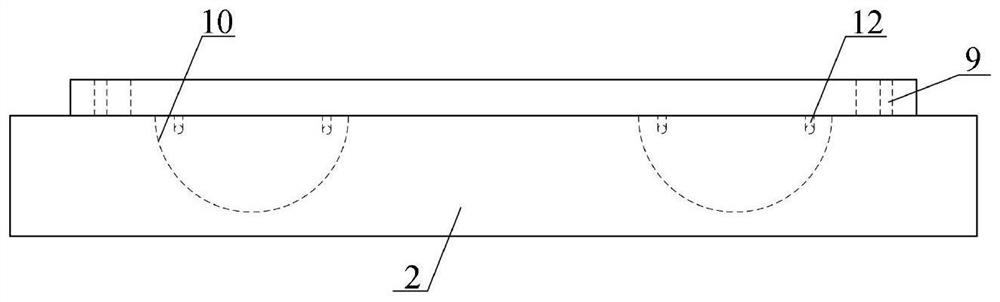

[0024] The lower connecting plate (1) is fixed on the lower end surface of the lower seat plate (2), and the upper surface of the lower seat plate (2) is provided with a fixing slot (9), a semi-cylindrical groove (10) and The oil injection hole (13), the stainless steel circular arc plate (3) is fixedly installed in the semi-cylindrical groove (10), and a plurality of elongated grooves (11) are arranged inside, and the elongated groove (11) ) is provided with a ball (4), the steel rod (5) forms a rolling contact with the ball (4) and the upper seat plate (6), and the dust cover (8) is embedded in the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com