Method for judging oil leakage of benzene hydrogenation heat conduction oil heat supply system

A heat supply system and heat transfer oil technology, which can be used to detect the appearance of fluid at the leakage point, test the fluid tightness, test the machine/structural components, etc., can solve the problem of slow maintenance efficiency and the leakage of heat transfer oil heating system Difficulty and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

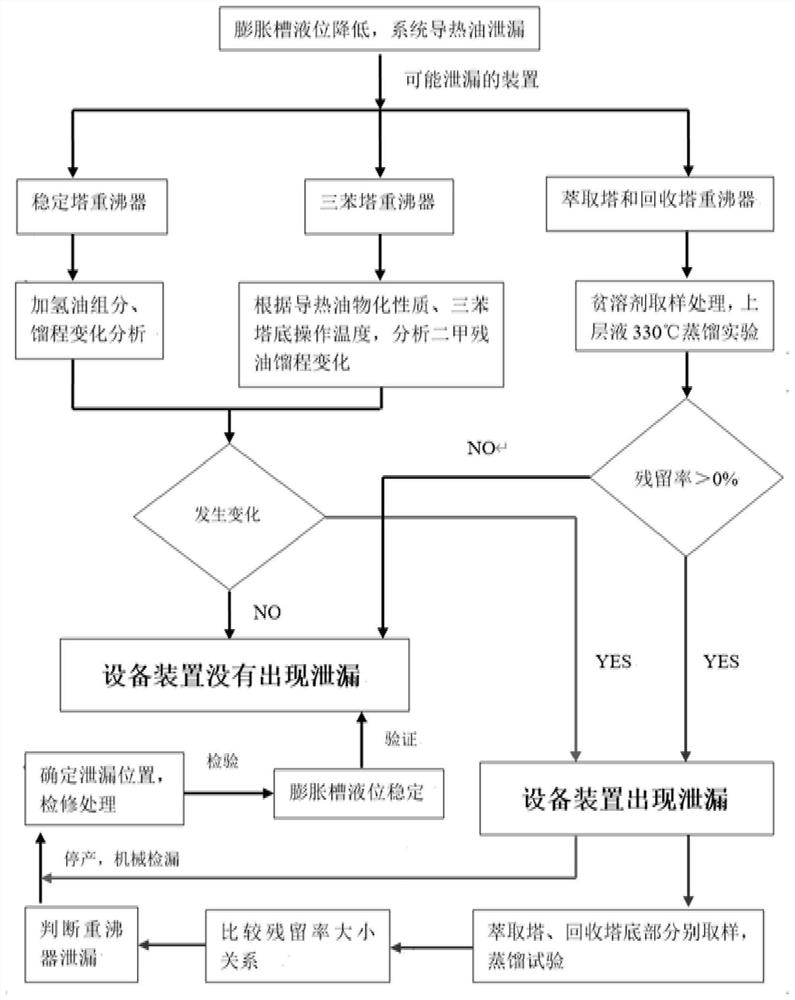

[0043] Such as figure 1 As shown, a method for judging oil leakage of a benzene hydrogenation heat transfer oil heating system comprises the following steps:

[0044] S1: Determine whether the liquid level of the expansion tank in the heat transfer oil heating system is lowered, and if it is lower, proceed to the next step; because the entire heat transfer oil heating system is an internal circulation system, the content of the heat transfer oil is relatively stable, and the expansion tank and the heat transfer oil main pipe Connect, so the liquid level in the expansion tank decreases, which indicates that there is oil leakage in the system, so a preliminary judgment of leakage is made through the expansion tank;

[0045] S2: Sampling and analyzing the substance in each reboiler in the heat transfer oil heating system to determine the specific leaking reboiler; specifically, when the boiling point of the substance in the reboiler is higher than or equal to the boiling point of...

Embodiment 2

[0061] Basically the same as in Embodiment 1, in order to ensure the accurate performance of the judgment of the entire heat transfer oil heating system, a liquid level sensor is installed in the expansion tank in step S1 in this implementation, the liquid level sensor is electrically connected to the PLC control system, and the liquid level sensor detects the expansion The liquid level signal in the tank is fed back to the PLC control system, the operator can observe the liquid level of the expansion tank through the PLC control system, the data feedback is accurate and the feedback efficiency is high; further, the outer surface of the liquid level sensor is set There is a protective cover, and the setting of the protective cover can ensure that the liquid level sensor is not disturbed by the external environment, and further ensure the stability of the liquid level sensor. In order to facilitate the sampling of each reboiler, a sampling port is provided on each reboiler, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com