Composite material bearingless rotor wing stability augmentation device

A stabilization device and composite material technology, applied in special data processing applications, instruments, electrical digital data processing, etc., to achieve the effect of improving calculation efficiency and optimal aeroelastic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

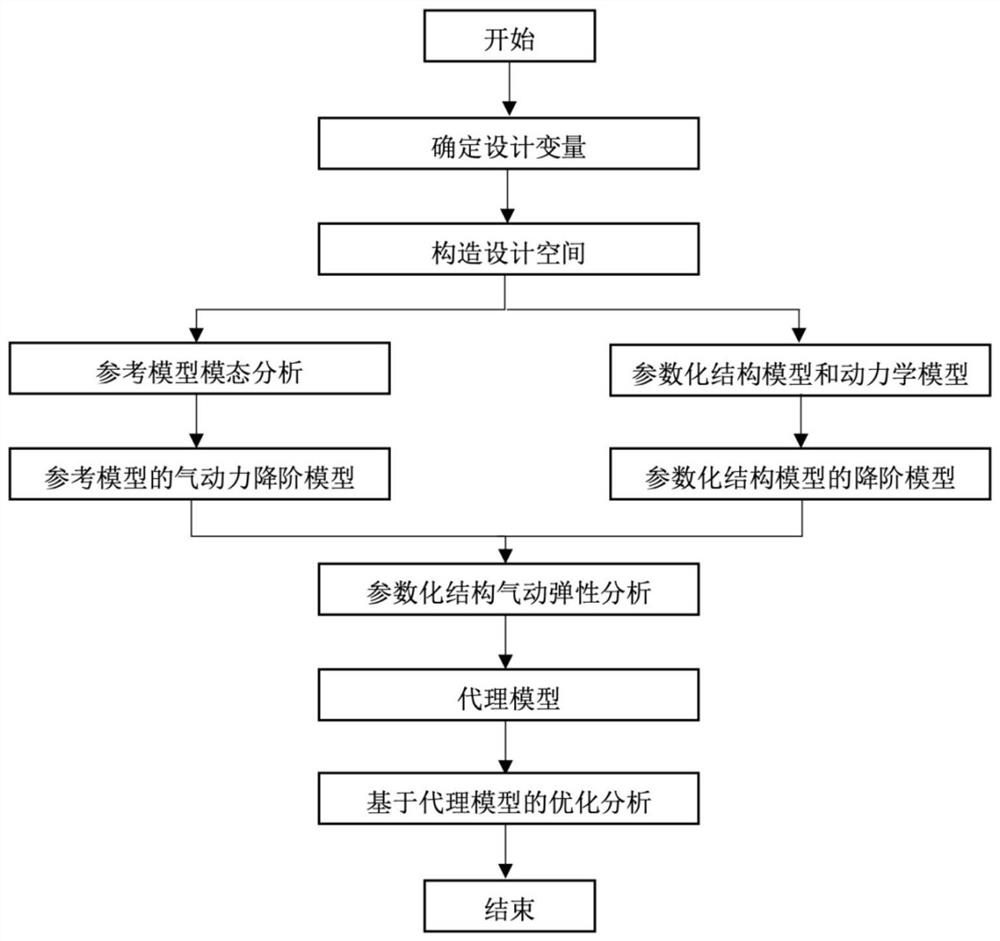

Method used

Image

Examples

Embodiment

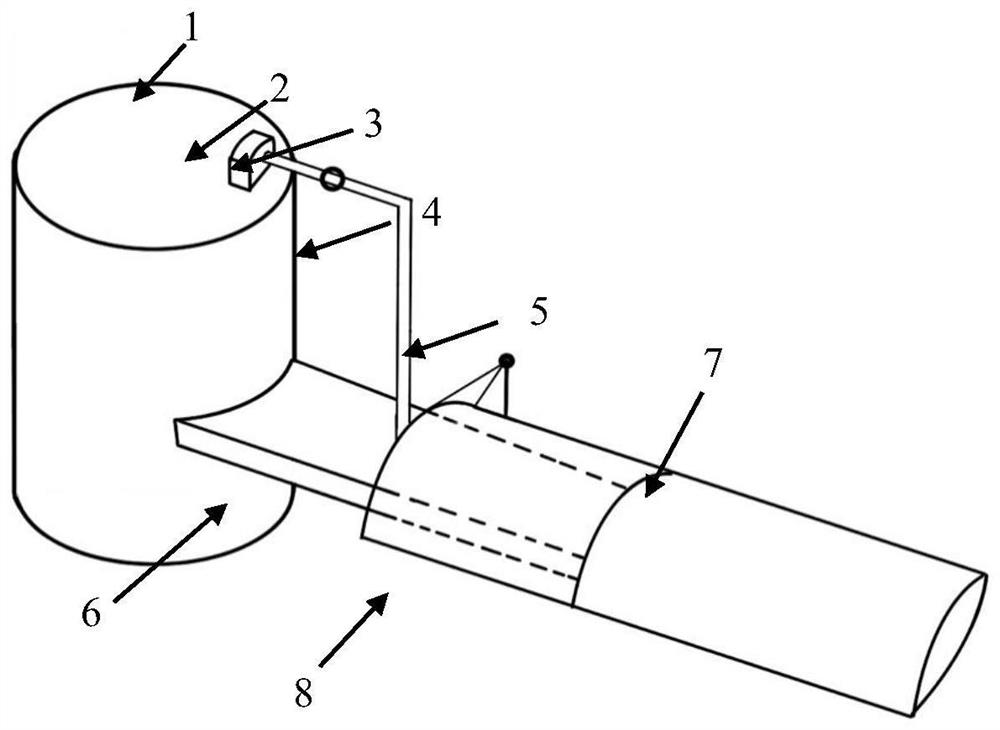

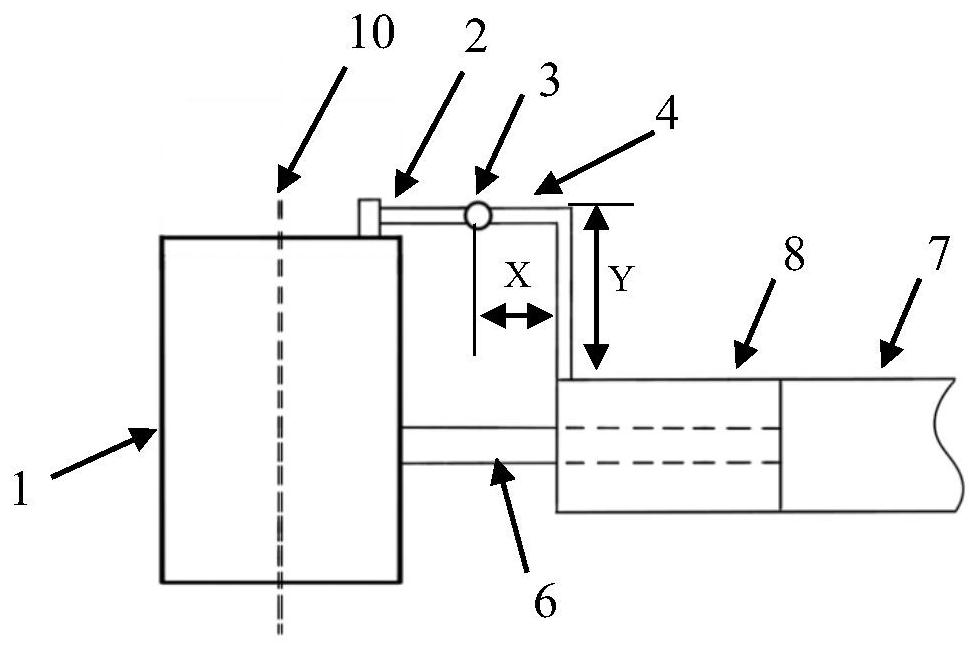

[0107] The characteristic parameters of a bearingless rotor are as follows: number of blades N=4, rotor radius R=0.96m, chord length c=0.081m, rotor rated speed Ω=817rpm. The radius of the circular shimmy pin, the length of the horizontal part and the length of the vertical part are used as design variables. In order to simplify the calculation process, the shimmy pin is set as a rigid body structure in this example, so the radius basically has no effect on it, while the shimmy pin The length of the horizontal part is the minimum, that is, X=0. At this time, the shimmy pin is directly connected to the propeller hub through the central support 5, and the design interval of the vertical part length of the shimmy pin is [0 0.012R]. The technical solution provided by the present invention is obtained: when the length of the vertical part of the shimmy pin is 0.012R, the real part of the eigenvalue representing the aeroelastic stability is the smallest, that is, the shimmy damping i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com