Transmission device suitable for cadmium telluride battery thin-film solar cell thermal process

A technology for solar cells and transmission devices, applied in transportation and packaging, circuits, photovoltaic power generation, etc., can solve problems such as lowering product yield, glass substrate scratches, glass bending, etc., reducing contact area, improving stability, guaranteeing The effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

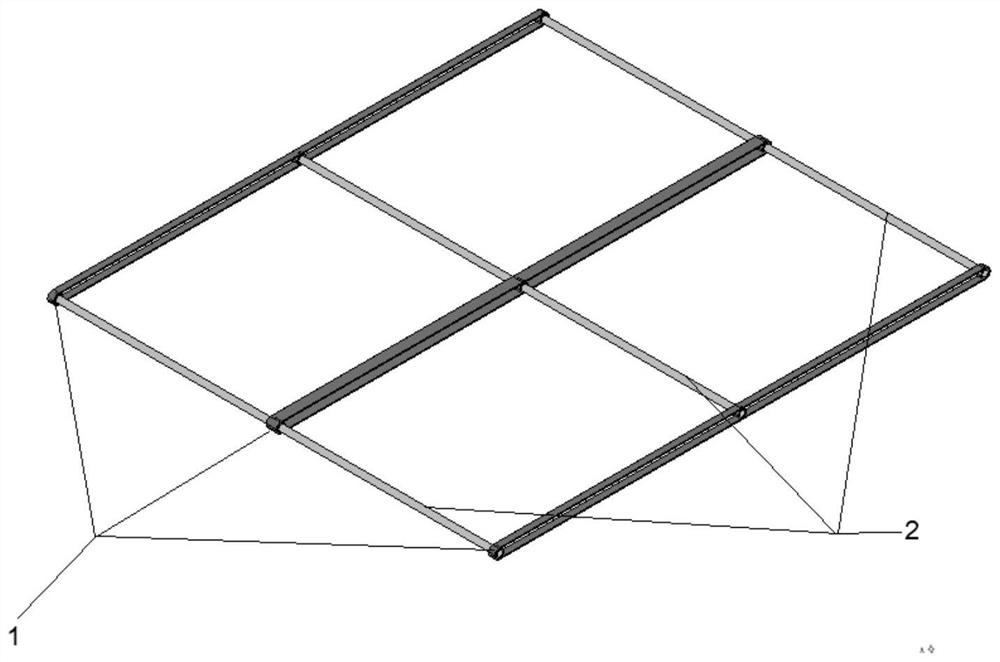

[0027] This embodiment provides a transmission device suitable for the thermal process of cadmium telluride battery thin-film solar cells, which includes several transmission units arranged adjacent to each other in sequence. The transmission unit includes a steel belt, a roller, a servo motor and a speed reduction mechanism; A steel belt is slidingly sleeved at both ends and the middle of the shaft; the two ends of the steel belt are slidably supported by rollers, and the middle of the steel belt is slidingly sleeved to connect with a roller; the surface of the steel belt is provided with anti-skid patterns; the roller and the servo motor Electromechanical connection, servo motor and reduction mechanism electric connection; the material of the steel belt is 316L.

[0028] As a preferred embodiment, the steel belt width is 10mm; the distance between two adjacent steel strips is 0.8m; the length of the steel strip is 1.8m; the distance between two adjacent rollers is 1.0m; the l...

Embodiment 2

[0031] This embodiment provides a transmission device suitable for the thermal process of cadmium telluride battery thin-film solar cells, which includes several transmission units arranged adjacent to each other in sequence. The transmission unit includes a steel belt, a roller, a servo motor and a speed reduction mechanism; A steel belt is slidingly sleeved at both ends and the middle of the shaft; the two ends of the steel belt are slidably supported by rollers, and the middle of the steel belt is slidingly sleeved to connect with a roller; the surface of the steel belt is provided with anti-skid patterns; the roller and the servo motor Electromechanical connection, servo motor and reduction mechanism electric connection; the material of the steel belt is 316L.

[0032] As a preferred embodiment, the steel width is 8mm; the distance between two adjacent steel strips is 0.8m; the length of the steel strip is 1.8m; the distance between two adjacent rollers is 0.9m; the length ...

Embodiment 3

[0035] This embodiment provides a transmission device suitable for the thermal process of cadmium telluride battery thin-film solar cells, which includes several transmission units arranged adjacent to each other in sequence. The transmission unit includes a steel belt, a roller, a servo motor and a speed reduction mechanism; A steel belt is slidingly sleeved at both ends and the middle of the shaft; the two ends of the steel belt are slidably supported by rollers, and the middle of the steel belt is slidingly sleeved to connect with a roller; the surface of the steel belt is provided with anti-skid patterns; the roller and the servo motor Electromechanical connection, servo motor and reduction mechanism electric connection; the material of the steel belt is 316L.

[0036] As a preferred embodiment, the steel width is 9mm; the distance between two adjacent steel strips is 0.9m; the length of the steel strip is 1.7m; the distance between two adjacent rollers is 0.9m; the length ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap