Packaging device, preparation method thereof and electronic equipment

A technology for packaging devices and electronic components, which is applied in the field of electronics and can solve the problems of increasing the area of packaging devices and detrimental to the lightweight of electronic equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

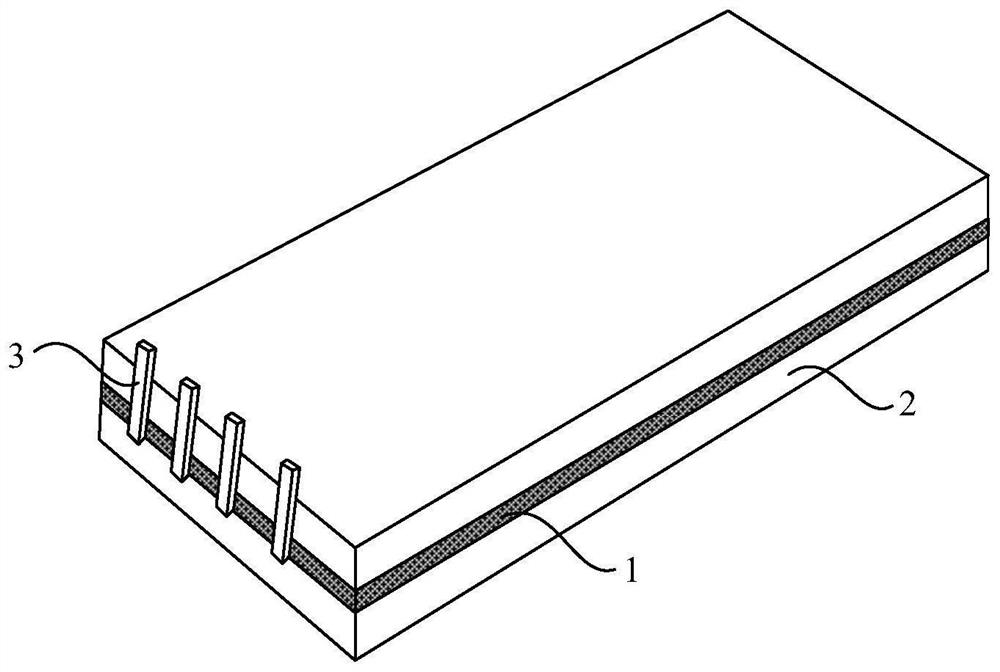

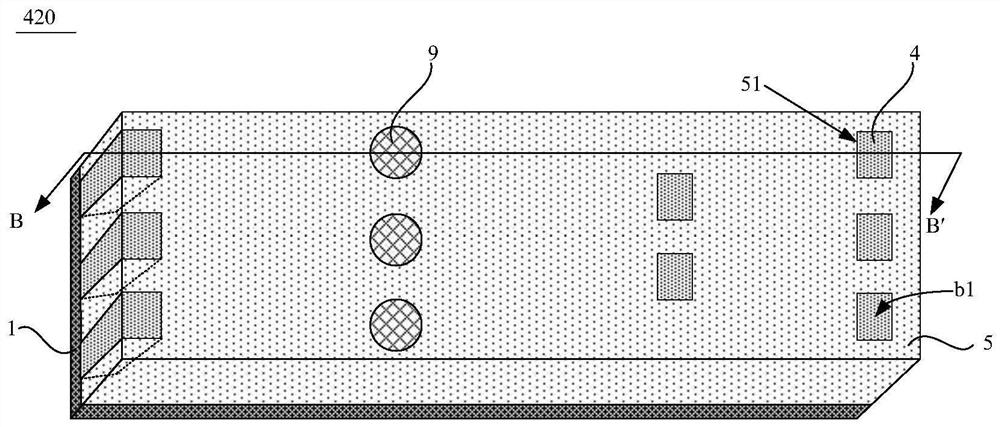

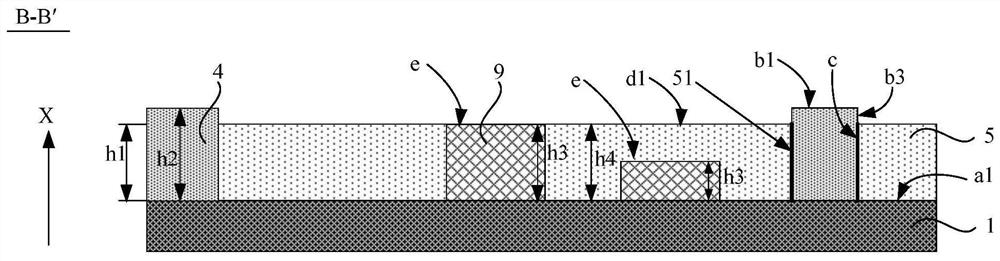

[0087] like image 3 As shown, the packaging device 420 includes a circuit board 1 , a first pin 4 , a first electronic component 9 , and a first plastic packaging layer 5 .

[0088] The circuit board 1 has a first surface a1.

[0089] The first plastic sealing layer 5 covers the first surface a1 ; the first plastic sealing layer 5 includes at least one first channel 51 , and the first channel 51 penetrates the first plastic sealing layer 5 along the first direction X.

[0090] The first channel 51 is a through hole, and the first channel 51 is located in the area surrounded by the side d2 of the first plastic sealing layer 5 .

[0091] It can be understood that the first passage 51 here is a through hole relative to the first molding layer 5 , that is to say, the first passage 51 penetrates the first molding layer 5 . However, for the entire packaged device, the first channel 51 is a blind hole, and the first channel 51 does not penetrate the circuit board 1 . Wherein, the...

example 2

[0123] like Figure 8a and Figure 8b (along Figure 8a As shown in the cross-sectional view in the D-D' direction), the difference between the second example and the first example is that the first passage 51 for placing the first pin 4 includes a connected first sub-channel 511 and a second sub-channel 512. The second sub-channel 512 is arranged closer to the circuit board 1 than the first sub-channel 511 .

[0124] like Figure 9a As shown, the first pin 4 and the first electronic component 9 are independently arranged in a first channel 51 .

[0125] like Figure 9b (along Figure 9a As shown in the cross-sectional view in the E-E' direction), there is a gap z between the surface of the first pin 4 facing the inner wall c1 of the first sub-channel 511 and the inner wall c1 of the first sub-channel 511 .

[0126] In some implementation manners, the above-mentioned gap z can be formed on the basis of the first plastic encapsulation layer 5 of Example 1 by means of lase...

example 3

[0134] like Figure 11a As shown, the difference between Example 3 and Example 1 and Example 2 is that the first channel 51 is a through groove, and the first channel 51 is located on the side d2 of the first plastic sealing layer 5 .

[0135] In this case, the groove wall c of the through groove serves as a side d2 of a part of the first plastic sealing layer 5 .

[0136] The side d2 of the first plastic encapsulation layer 5 not only intersects the first surface a1 , but also intersects the upper surface d1 of the first plastic encapsulation layer 5 away from the circuit board 1 .

[0137] In some embodiments, such as Figure 11a As shown, along the first direction X, the cross-sectional area of the through groove does not change. like Figure 11b (along Figure 11a As shown in the view in the Y direction), along the first direction X, the projection of the groove wall of the through groove is two parallel lines.

[0138] In some embodiments, such as Figure 12a As s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com